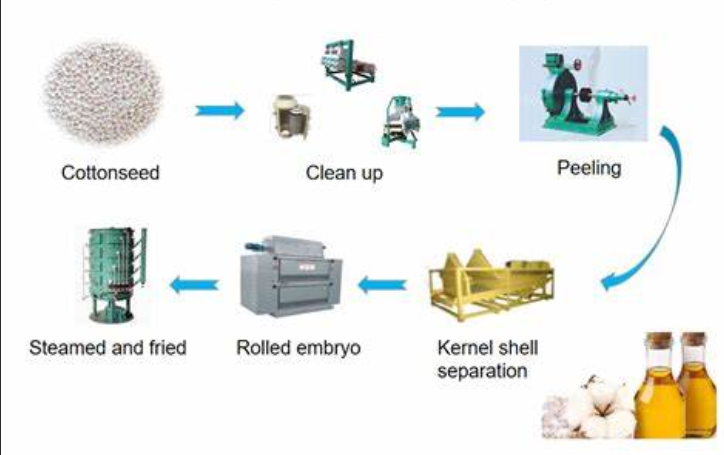

Cottonseed oil is an oil extracted from cottonseed. The traditional cottonseed oil extraction process involves pressing or extraction. The common cottonseed oil processing flow: cottonseed – cleaning – shelling – shell kernel separation – embryo rolling – high moisture steaming – pre-pressing – solvent extraction.

Cottonseed oil contains a large amount of essential fatty acids, among which linoleic acid has the highest content, which can reach 44.0-55.0%. In addition, cottonseed oil also contains 21.6%-24.8% palmitic acid, 1.9-2.4% stearic acid, 18%-30.7% oleic acid, and 0-0.1% arachidic acid. Cottonseed oil can be used for cooking and consumption. It can generally produce soap, glycerin, ink, lubricating oil, and pesticide solvents in industry.

We have exported a large number of cottonseed oil press machine to many countries. In addition, we also undertook many cottonseed oil mill project worldwide, like Afghanistan. If you want to know the cost to setup a copmlete cottonseed oil mill plant, or the price of a single cottonseed oil processing machine, please contact us directly. Here, you can only the a satifying feedback.

Small Cottonseed Oil Milling Plant

This small small oil mill is not only suitable for cotton seeds, it is also ideal choice for extracting oil from many other oil seeds and nuts, such as mustard seed, peanut, flaxseed, linseed, poppyseed, groundnuts, sesame seed, canola seed, sunflower seed, soybeans, etc. The equipment for running a small scale oil-pressing mill may include screw elevator, cotton seed oil expeller, cleaning sieve and filter press. The following is our HOT Sale vegetable seeds oil pressing line. It is advantageous if you have space, economic or labor constraints.

- Cottonseeds Pretreatment – Cleaning, Dehulling, Softening, Flaking

Cotton seeds are cleaned by air, magnetic separation or cleaning machine, and then fed evenly into the dehulling machine (sheller) by quantitative feeder. The husking process requires neat cotton kernel size and low level of husked powder. After kernel separation, the hull content of in the cotton kernel should not exceed 10%. The softening effect will have direct effect on the oil extraction process as well as the quality of final cottonseed oil. So, it is very important to control the softening temperature, time and moisture. Cottonseed generally USES three or four layers of vertical steam frying pan. The flaking process requires the flake thickness should not exceed 0.5mm and lower fines content. The final flakes are dried.

- Cottonseed Oil Pressing – Small to Medium Scale Oil Mill Plant

Most of small and medium cottonseed oil mill plant uses screw oil press machine to press oil out from the cottonseed kernels by mechanical pressure so as to improve the oil yield and reduce the investment cost. Screw oil mill plant is also used to pre-press oil before starting solvent extraction.

- Cottonseed Oil Extraction – Medium to Large scale Oil Processing Plant

For large scale cottonseed oil processing plant, the most widely used method for cottonseed oil extraction is solvent extraction, which can meet the large production demand for cottonseed oil. But it usually requires very large investments.

- Cottonseed Oil Refining – Medium to Large scale Oil Processing Plant

Before the oil can be used, the extracted cotton seed oil has to be refined to remove waxes, gums, pigment and other impurities. The main types of refining include degumming, neutralizing, decolorizing, deodorizing and dewaxing. To choose what process to use for refining, it will depend on the type of raw material.

Our cottonseed oil mill machinery (oil press machine & refiney machine) engineered to be compact, durable, reliable and efficient is ideal for anyone who desires to set up their own oil mill plant and produce cooking / edible oil for business purpose or own use. Feel free to inquire for more details of our equipment or ask for a customized equipment list depending on your situation and the cheapest price!

Large Scale Cottonseed Oil Processing Plant

The complete cotton processing plant includes cottonseeds pretreatment and pressing workshop, cottonseed cake solvent extraction workshop and crude cottonseed oil refinery workshop. There are two main extraction methods of cottonseed oil: one is the pretreatment pressing method, and the other is the solvent extraction method. Different extraction methods use different cotton seed oil processing machine, so this article will introduce the complete cotton seed oil processing plant.

Pretreatment and Pre-pressing of Cotton Seeds

- The Delinting Machine / Flanneler

Cottonseeds that have lint will have to go through the delinting machine to remove the lint.

- Cleaning of Cottonseeds

To remove impurities, the cottonseeds will have to go through a cleaning process that includes the use of a vibrating screen, magnetic separator, and winnower. The magnetic separator is used for removing tiny metallic materials. The vibrating screen is needed to remove large impurities. The winnower can get rid of dust and other light impurities.

- Removing the Hulls

Hulls makeup about 40% to 55% percent of cottonseeds and also has 0.3% to 1% oil. You can get 14% to 25% oil from cottonseed and 30% to 40% oil from the kernels. The hulls also have residue wax, pesticide, brown pigment, and lint, which can compromise the quality of cottonseed products. Hence, removing the hulls is very important. The hulls, on the other hand, can be used as livestock feed and growing medium for mushrooms.

The common choice of equipment for removing cottonseed hulls is a toothed roller crusher. It has a huge capacity, high kernel rate, good hulling rate, better production, easy low maintenance, and low power consumption.

- Separating of Hull and Kernel

Separating the hulls and kernels can improve the quality of the meal and oil. The vibrating screen is used by cottonseed oil mill plant for this. The hulls go through the hull beater to remove residual kernel pieces.

- Flaking the Cottonseeds

This converts cottonseeds into flakes as well as removes the cell walls that decrease oil yield and its yielding speed. Processing plants use flaking rollers to get ensure that the thickness of the flakes is uniform. These rollers are durable and high-performance.

- Cooking the Flakes

A vertical cooker is used by a cottonseed oil mill plant to cook the flakes. The flakes go straight from the flaking roller to the vertical cooker. The temperature and moisture of the flakes are adjusted in the cooker to reduce gossypol content and improve crude oil quality.

Cottonseed Oil Pressing & Filteration

- Cottonseed Oil Pressing / Expelling (by using Mechanical Screw type Oil Press)

Cottonseeds can be pre-pressed before they get sent directly to the refinery plant. To handle 20 tons of cottonseed per day, the solvent extraction method is used with cottonseed oil prepress to take parts of the oil. The machine used for the job has a large capacity and its cake leaves less residual, which makes it easy for the solvent to penetrate.

- Oil Filtering

Residual oil can be collected with the use of an oil residue scraper. Leaf Filter is used for filtering the oil from the cottonseed. The leaf filters used by processing plants are precise and can easily remove oil residue. The oil will then be pumped into the crude oil tank while the pre-pressed cake is taken for solvent extraction.

Cottonseed Cake Solvent Extraction Workshop

- Extracting Oil from Cottonseed Cakes by Solvent

The extraction of oil involves using an organic solvent, which allows the extraction of oil from the cake inside the extractor. Other extractors such as rotocel extractor, towline extractor and loop type extractor for better production. The solvent with the wet meal and miscella are collected after oil extraction. To remove the fines, the miscella will be pumped into the hydrocyclone. Next, the miscella is taken to the miscella tank.

- Removing the Solvent

To remove the solvent from the meal, the wet meal goes through the DTDC desolventizing in the plant.

- Solvent Recovery

After entering the condensing system, the recycled solvent goes through the holding tank for circulation. Water is extracted and taken to a water tank. The gas from the plant goes through a mineral oil system to have the solvent recovered from it. Recovering the solvent can help lessen the consumption of solvent and make production safer.

Fractionation and Refining Crude Cottonseed Oil

Refining crude cottonseed oil to produce edible / cooking oil. It involves bleaching, De-acidification, deodorization, and degumming. Fractionation can get solid and liquid oil through solid and liquid separation and cooling crystallization.

We can offer all kinds oil oil machinery including oil mill, filter press, oil refinery machine and so on. Our cottonseed oil mill machinery has been used in numerous reputed cooking and vegetable oil plant, solvent extraction plants and refineries all across the nation. Welcome inquiry the details of our machinery!

Major Cottonseed Oil Producing Countries

Cottonseed includes hull and kernel, as hull contains fibers and linters, and the kernel is full of protein, carbohydrate, vitamins, minerals and sterols. Cotton seed oil is one of the most unsaturated edible oils. Though cotton cultivation dates back to several centuries, the cottonseed oil production is relatively new branch in world industry. In 1793 the first oil processing plant emerges, but it was only in the twentieth century that it was utilized for commercial purposes. Nowadays, cottonseed oil takes the fifth place in all edible oils.

| TOP 10 Countries of Cottonseed Oil Production (1000 MT) | |

|---|---|

| China | 1,382 |

| India | 1,370 |

| Brazil | 592 |

| Pakistan | 469 |

| United States | 277 |

| Turkey | 244 |

| Uzbekistan | 189 |

| Australia | 100 |

| Mexico | 96 |

| Mali | 63 |