The Palm Fruit Oil Press Machine is specifically designed for extracting oil from palm fruit with maximum efficiency. Our Palm Fruit Oil Press Machine combines cutting-edge technology with robust engineering to meet the needs of modern palm oil producers. Designed for efficiency, reliability, and high yield, this palm oil press machine is the ultimate solution for extracting premium-quality palm oil. Whether you’re a small-scale palm oil producer or an industrial large palm oil production plant, this machine is tailored to maximize productivity while maintaining sustainability and cost-effectiveness.

| Palm Fruit Oil Press Machines | |||

| Model | Picture | Specification | |

| 0.5TPH Palm Fruit Oil Press |  |

Processing capacity (FFB) TPH | 0.5 |

| Number of screws | Single screw | ||

| Spindle speed (r/min) | 25~35 | ||

| Feed temperature (℃) | 90-95 | ||

| Cake residual oil (%) | ≤8 | ||

| Palm kernel damage rate (%) | ≤15 | ||

| Motor power (kw) | 5.5 | ||

| Dimensions (mm) (L×W×H) | 1562×720×1298 | ||

| Weight(kg) | 450 | ||

| 1TPH Palm Fruit Oil Press |  |

Processing capacity (FFB) TPH | 1 |

| Number of screws | Single screw | ||

| Spindle speed (r/min) | 15~20 | ||

| Feed temperature (℃) | 90-95 | ||

| Cake residual oil (%) | ≤8 | ||

| Palm kernel damage rate (%) | ≤15 | ||

| Motor power (kw) | 7.5 | ||

| Dimensions (mm) (L×W×H) | 2410×850×930 | ||

| Weight(kg) | 620 | ||

| 2TPH Palm Fruit Oil Press |  |

Processing capacity (FFB) TPH | 2 |

| Number of screws | Single screw | ||

| Spindle speed (r/min) | 15~20 | ||

| Feed temperature (℃) | 90-95 | ||

| Cake residual oil (%) | ≤8 | ||

| Palm kernel damage rate (%) | ≤15 | ||

| Main motor power (kw) | 11 | ||

| Dimensions (mm) (L×W×H) | 2900×1050×1245 | ||

| Weight(kg) | 1137 | ||

| 3TPH Palm Fruit Oil Press |  |

Processing capacity (FFB) TPH | 3 |

| Number of screws | Twin screw, hydraulic compression | ||

| Spindle speed (r/min) | 11 | ||

| Feed temperature (℃) | 90-95 | ||

| Cake residual oil (%) | ≤7 | ||

| Palm kernel damage rate (%) | ≤10 | ||

| Main motor power (kw) | 11 | ||

| Hydraulic pump station motor power (kw) | 1.5 | ||

| Dimensions (mm) (L×W×H) | 3100×1300×790 | ||

| Weight(kg) | 1800 | ||

| 5TPH Palm Fruit Oil Press |  |

Processing capacity (FFB) TPH | 5 |

| Number of screws | Twin screw, hydraulic compression | ||

| Spindle speed (r/min) | 11 | ||

| Feed temperature (℃) | 90-95 | ||

| Cake residual oil (%) | ≤7 | ||

| Palm kernel damage rate (%) | ≤10 | ||

| Main motor power (kw) | 15 | ||

| Hydraulic pump station motor power (kw) | 1.5 | ||

| Dimensions (mm) (L×W×H) | 3900×1500×850 | ||

| Weight(kg) | 2500 | ||

| 10TPH Palm Fruit Oil Press |  |

Processing capacity (FFB) TPH | 10 |

| Number of screws | Twin screw, hydraulic compression | ||

| Spindle speed (r/min) | 10.5 | ||

| Feed temperature (℃) | 90-95 | ||

| Cake residual oil (%) | ≤7 | ||

| Palm kernel damage rate (%) | ≤10 | ||

| Main motor power (kw) | 22 | ||

| Hydraulic pump station motor power (kw) | 1.5 | ||

| Dimensions (mm) (L×W×H) | 4250×1550×900 | ||

| Weight(kg) | 3600 | ||

| 15TPH Palm Fruit Oil Press |  |

Processing capacity (FFB) TPH | 15 |

| Number of screws | Twin screw, hydraulic compression | ||

| Spindle speed (r/min) | 10.5 | ||

| Feed temperature (℃) | 90-95 | ||

| Cake residual oil (%) | ≤7 | ||

| Palm kernel damage rate (%) | ≤10 | ||

| Main motor power (kw) | 30 | ||

| Hydraulic pump station motor power (kw) | 1.5 | ||

| Dimensions (mm) (L×W×H) | 4450×1650×960 | ||

| Weight(kg) | 4500 | ||

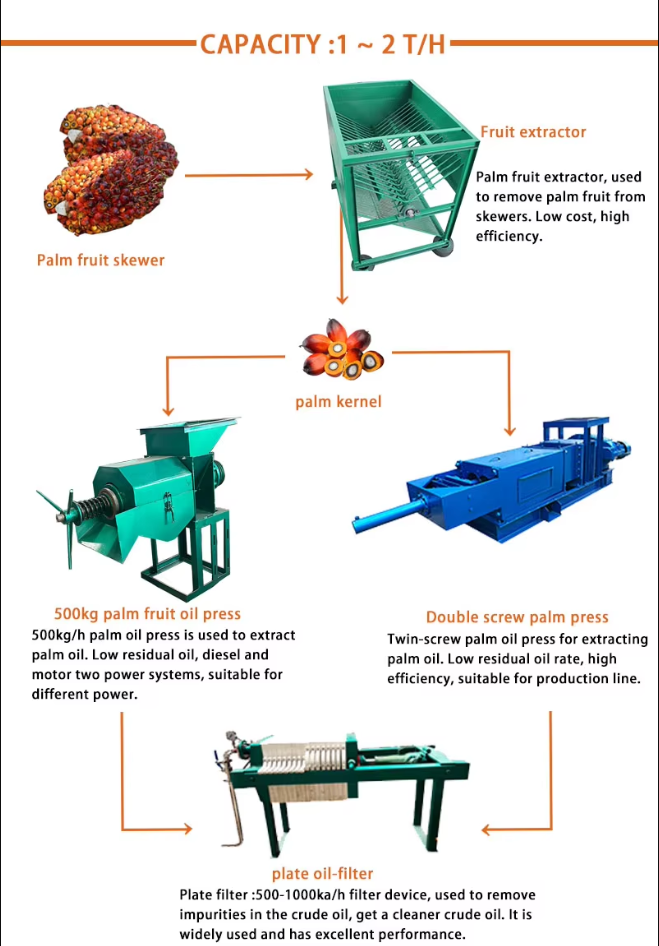

1-2T/H Palm Oil Production Line

The process of the 1-2t/h palm oil production line is close to the advanced process of large palm oil factories. The required palm oil processing machine mainly includes palm fruit sterilization machine, palm fruit threshing machine, palm fruit digesting machine, palm oil pressing machine, palm oil clarification machine and plate and frame filter. Steam sterilization is used for palm fruit sterilization process, which can shorten the time and improve efficiency. However, the loading and unloading of fruits during the sterilization process still require manual operation, which is a semi-automatic configuration in the front and fully automatic configuration in the back. This hybrid palm oil processing machine is also a reliable choice.

5T/H Fully Automated Palm Oil Production Line

The configuration of the 5t/h fully automatic palm oil production line is completely based on the technology of large palm oil factories. It has a fully automatic vertical steam sterilization tank, which not only has a short sterilization time but also can complete automatic feeding and discharging. The palm fruit bunch conveyor adopts a scraper conveyor, which saves labor and can produce continuously for 24 hours.

10-100T/H Large Scale Palm Oil Production Line

More than 10t/h large scale palm oil production line will be designed in full accordance with the palm oil processing process of large palm oil factories. Not only can the entire palm oil processing process be automated, and the palm oil processing machine is more complete, but the heavy oil pollution from the clarification link will be re-processed, and the remaining crude oil will be recovered to achieve the effect of making the best use of it. The more than 10t/h large scale palm oil production line will let your crude oil yield higher and make more profit!

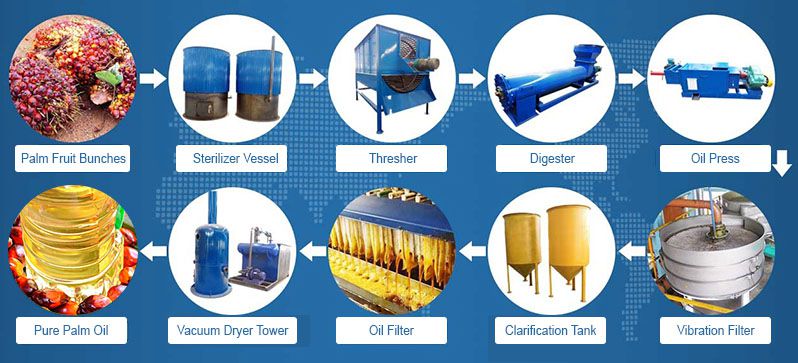

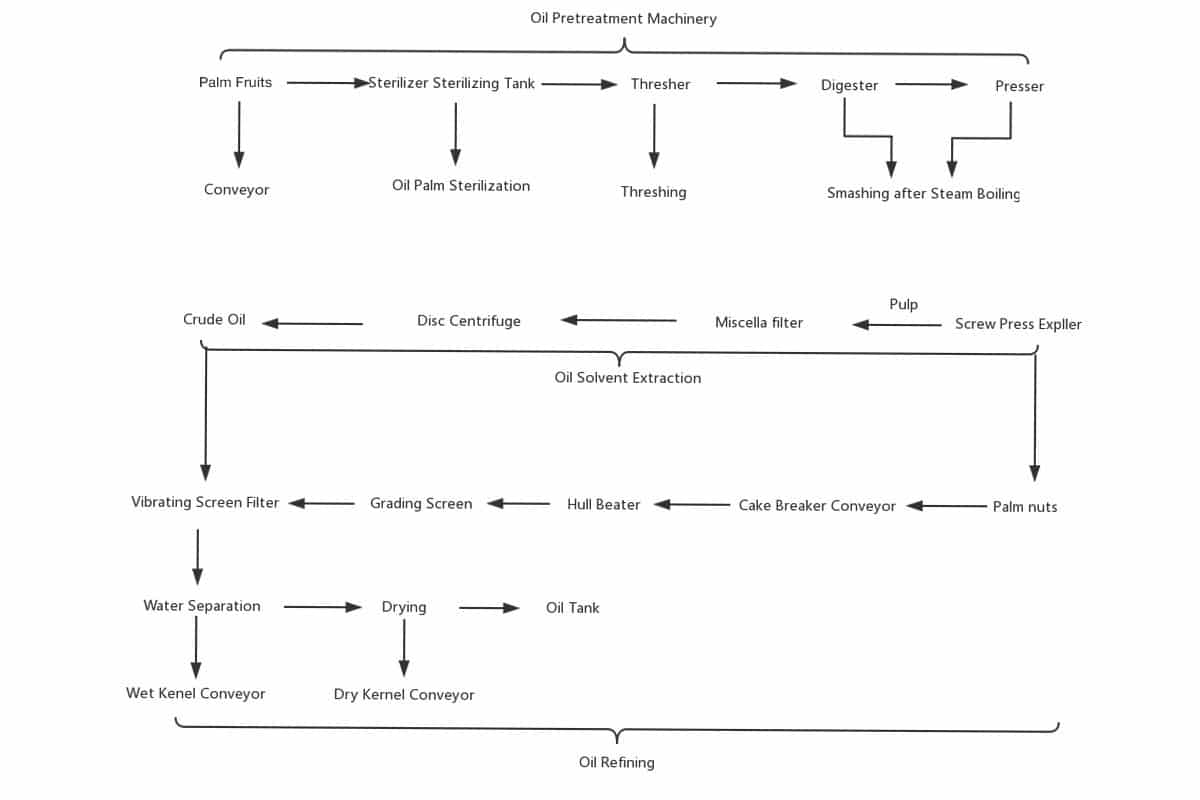

Flow chart of palm oil production line:

1.Raw materials reception section

1.1 The FFB bunch are transported to plant by truck, after be weighed by weighbridge, the FFB will be loaded down to FFB loading area.

1.2 FFB will fall down to the FFB loading conveyor through the FFB loading hopper then conveyed to sterilizing station

2. Sterilizing section

The FFB are transported to sterilizer for sterilizing. It use high temperature to soften the fruit and kill the bacteria, this will increase the moisture content of fruit and separte the fruit and separate the fruits easily, so finally it will easy to get oil and separate palm kernel, also avoid the raising of free fatty acid. From picking to sterilizing station, the time shall not over 24 hours.

3. Threshing section

The palm fruit proportion is about 60% of the FFB. In this section, we always use rotating drum thresher to separate palm fruit from the bunches.

The FFB are transported to sterilizer for sterilizing. It use high temperature to soften the fruit and kill the bacteria, this will increase the moisture content of fruit and separte the fruit

4. Pressing Section

Transport the palm fruits to the digester to mix and cook again to separate the palm pulp and nut, the use double screw presser to get crude palm oil, which improve the production efficiencey greatly.

5. Clarification section

The pressed CPO contains some water and other impurities, we need to clarify the CPO into sludge oil and pure oil. The pure oil will be dried then transport to crude oil tank, while the sludge oil will through centrifuge for recovery.

6. Palm kernel recovery section

The pressed palm fiber cake gets into the cake breaker then get into the winnowing system to separate the fiber and nut. Then nut will be crushed to get shell and kernel. Through winnowing and washing system to separate the shell and kernel. The shell ca be used as fuel for boiler, the kernel will be dried for storage.

If you are interested in palm oil processing machine or palm oil production line, feel free to contact us and we will supply the good-quality equipment and sweet service for you.