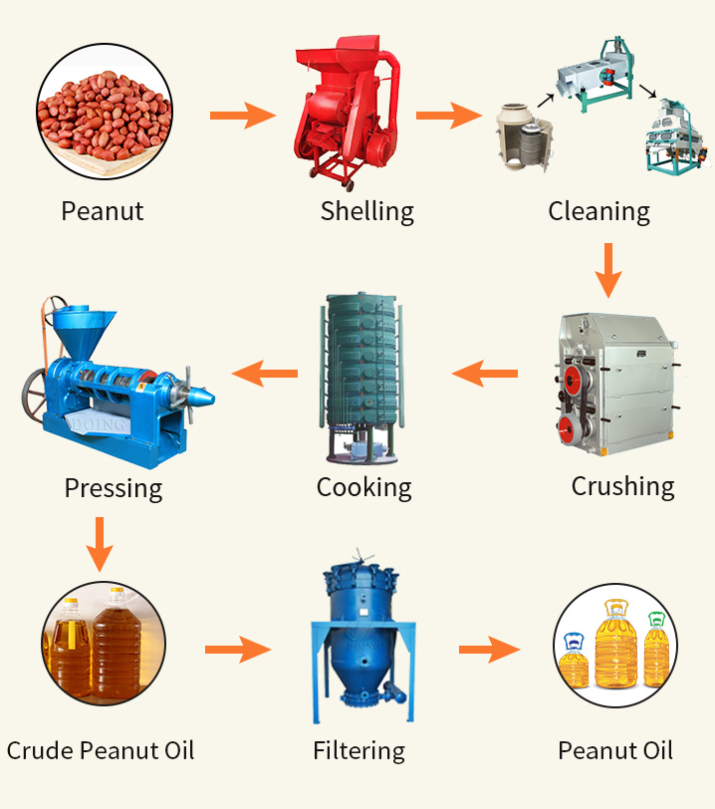

Peanut oil, also known as groundnut oil, can be extracted by pressing, pre-pressing and solvent extraction, etc. Among them, the most widely used extraction method is pressing. The processing of peanut oil is mainly based on hot pressing, because the hot pressing process can get rich peanut flavor and keep the nutritional components and physiological active components in peanut to the maximum extent. Next, we will introduce the production process of extracting peanut oil by pressing technology.

Peanut Oil Press Machine

Type 1: Screw Peanut Oil Press Machine

| Machine Advantages:

* Automatic |

|

Capacity:1t/d, 3t/d, 5t/d, 8t/d, 10t/d, 10-20t/d, 30t/d

Suitable for:sunflower seed, peanuts, flax seed, sesame,rapeseed, cottonseed, soybean and more than 30 kinds of oil seeds

Type 2: Peanut Oil Press Machine With Filter

| Machine Advantages:

* Multipurpose |

|

Capacity: 2t/d, 3t/d,4t/d, 5t/d, 6t/d, 8-10t/d

Suitable for:sunflower seed, peanuts, flax seed, sesame,rapeseed, cottonseed, soybean and more than 30 kinds of oil seeds

Type 3: Large Peanut Oil Press Machine

| Machine Advantages:

* Automatic |

|

Capacity:9-10t/d, 10-50t/d, 50-80t/d, 80-150t/d, 150-300t/d,300t/d

Suitable for:sunflower seed, peanuts, flax seed, sesame,rapeseed, cottonseed, soybean and more than 30 kinds of oil seeds

Peanut Oil Production Line

Small Scale Peanut Oil Pressing Line

This small scale peanut oil pressing line is fully adopted mechanical driven, it connects each oil processing machinery together to extract oil with higher oil yield and at the same time, change the single machines by manual into the semi continuous production line to liberate the workforce. It is really an ideal investing item with little investment, high production efficiency and high profits!

Features of the Peanut Oil Pressing Line

★ Easier to operate, easier to install and commissioning.

★ Need small investment, fewer land space, but with the complete function of the production.

★ Wide application that can make many other kinds of vegetable seeds and nuts, such as rapeseeds, cotton seeds, sunflower seeds, corn germ, palm kernel, sesame seeds and so on.

★ Need fewer labor than the single machines, only 2~3 persons can run the whole line

★ The semi-continuous can avoid the unstable material feeding caused by manual and can make the worker safety more under the higher temperature working situation.

Large Scale Peanut Oil Production Line

We offer you complete peanut oil production solutions. No matter small peanut oil plants from 1 TPD to 50 TPD, or large-scale peanut oil plants up to 5,000 TPD, we will work with you to make the best solution. Our peanut oil production line is a comprehensive, multi-stage setup designed to extract and refine oil from peanuts. Each stage, from cleaning and dehulling to oil extraction and refining, is critical to ensure high-quality, pure peanut oil that meets commercial standards. Small-scale setups rely on mechanical pressing for simplicity, while large-scale production lines utilize solvent extraction and advanced refining techniques to maximize output and meet market demand.

The main equipment for peanut oil production includes: cleaning equipment, crusher, flaking machine, cooker, oil press, extractor, desolventizer, refining equipment, as well as automatic filling and packaging equipment.

Our Process

- Advanced peanut pretreatment and pressing process, including sunflower seed cleaning – crushing – rolling – steaming and frying – pressing – three-stage filtration, etc., to maximize the oil yield.

- Solvent leaching process is used to improve the oil extraction rate, reduce production costs, and obtain maximum benefits.

- Physical refining and chemical refining processes can be selected to improve oil quality and remove impurities and free fatty acid.

Complete Set Groundnut Oil Refinery Plant

Peanut oil refinery plant is a set of machines, with which we can get standard edible peanut oil for cooking. In the production process of peanut oil refinery plant, we utilize the physical methods and chemical processes according to the different usage and requirements to get rid of the harmful impurities and needless substance in the crude peanut oil.

Refining Process of the peanut oil refinery plant

1>Degumming:Degumming removes gums as preparation for subsequent refining processes.

2>Deacidification:Deacidification removes FFA (free fatty acid) in crude oil.

3>Decolorization: Decolorization removes pigments in crude oil by adding white clay, which can improve the oil quality.

4>Deodorization : Deodorization removes odor in crude oil, which can improve the flavor, stability, color and quality of the oil.

Features of peanut oil refinery plant

- High-quality oil

The groundnut oil process used in a refinery plant ensures that the oil is of high quality and free from impurities. The extraction machines used ensure maximum yield and minimum waste, resulting in pure and healthy oil.

- Longer shelf life

Refining groundnut oil extends its shelf life, making it more stable and resistant to oxidation. A high-quality groundnut oil extraction machine enhances the oil’s overall quality, making it ideal for long-term storage.

- Increased profitability

Setting up a groundnut oil refinery plant for the groundnut oil process can be a lucrative business venture. The high-quality oil produced attracts a premium price, and the efficient extraction machines used in the process reduce production costs, increasing overall profitability.

- Health benefits

Refined groundnut oil is a rich source of healthy fats, vitamins, and antioxidants. These nutrients have various health benefits, including reducing inflammation, improving heart health, and supporting brain function.