Soybeans are quite important in the world today since it is an important source of food, protein, and oil. Soyabean oil is one of the most common products gotten from the soyabean crop. It is the most commonly used cooking oil in the US and in other countries around the world. This is because it is very nutritious and has lots of health benefits. Soyabean oil has low saturated fats, polyunsaturated fats, and omega-3 fatty acids. This makes it one of the healthiest choices of cooking oil available. Therefore, soybean oil is in high demand in the food industry. It also finds applications in the production of paints, solvents, adhesives, biodiesels, lubricants, and biocomposites. The increasing demand for soybean oil in food processing industry and the growing trend of soybean oil in biofuels has been the market forces of soybean oil production industry. If you are interested in soybean oil processing business, a reliable and experienced oil mill machinery supplier can help to to avoid detours and loss, lower soybean oil processing plant cost.

We are the leading oil processing machine manufacturer and supplier of best soybean manufacturing oil machines. Generally, the equipment for soybean oil production includes screw pressing machinery and solvent extraction equipment. In order to meet more customers’ needs, we provide one-stop service to help customers build up their own soybean oil processing plant for household or commercial uses, including equipment selection, manufacturing, installation and after-sale service, etc.. If you are interested in buying the best soybean oil machine at factory price, please contact us directly!

Soybean oil processing machine designed by our factory is the advanced edible oil processing machinery, characterized by the high oil output rate with good quality, simple design, easy to use and continuous operation. They can use for various raw materials, such as peanut, beans, rape and cottonseeds, sesame, olive, sunflower, coconut, grass seed etc.

Small Soybean Oil Production Line Setup Cost

soybean oil is indispensable in people’s daily life. In recent years, with the rapid development of the world soybean oil market, investing on soybean oil production line and establishing soybean oil plant are good choice for many investors.

However, many people do not know how to start a small scale soybean oil production line? They may have many questions, such as, How Much It Would Cost? What Equipment It Needed? How to Operate It Correctly? and more. In order to help more people to setup their own oil pressing line at low cost, Our company specially designed the small scale oil production line with capacity of 1tpd to 30tpd for optimal choice.

Small Soybean Oil Pressing Lines Setup Advantages

Oil pressing and production can be done in soybean oil mill plant. Usually there are three types of oil mill, small scale, medium scale and large scale. The conditions of starting a small scale soybean oil pressing line is relatively simple and easy, especially for novice in oil processing industry.

The small soybean oil pressing line we designed and built also can process cotton seeds, palm kernels, coconut, peanut, almond, prickly pear seeds, rapeseeds, mustard seeds, flaxseeds, sunflower seeds and more other oil-bearing plants and nuts. If you are searching for a reliable supplier to be your own oil mill plants, We won’t let you down. We have very rich experiences and professional technical personals in this sector.

- High oil output can get returns quickly

- It is versatile for various vegetable seeds

- It also features short cycle of installation and construction

- The whole oil pressing process is automated and can operate consistently

- Small scale oil pressing line usually requires small investment, less factory spaces and less labors. It is ideal and safe choice to enter into oil making business

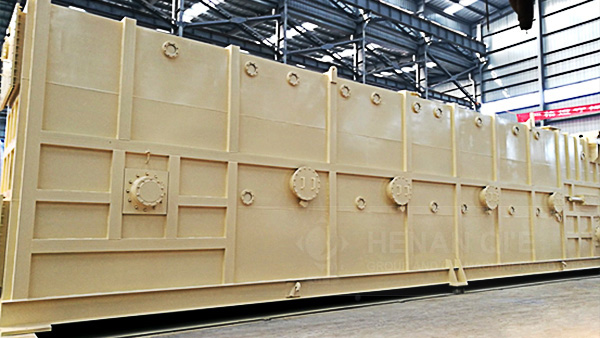

Large Soybean Oil Production Line

The soybean oil production line is a process in which soybeans are treated by pressing or solvent extraction method to obtain crude soybean oil and then refined to obtain edible soya oil.

The two oil production methods have different application scenarios and advantages and disadvantages, please contact us to provide you with a more suitable and complete soybean oil production line solution.

Section Introduction:

Pretreament workshop — solvent extraction workshop– Oil refinery workshop– Oil Filling workshop

Pre-treatment process feature:

1) Different combinations of process can oil processing various oil plants in one workshop.

2) Use special intensified pre-treatment technology for aroma soybean oil to make it more aroma.

3) Adopt advanced and reliable shelling technology to meet higher requirements for protein content in meal.

4) Extrusion treatment is used for raw materials with hard extraction, large-sized powder, and large capacity, which can reduce residual oil and solvent consumption, and increase the capacity by 50-80%.

5) The new technology of shelling and low-temperature treatment can ensure high protein and least denaturation.

Extraction workshop Brief Introduction:

In our design, the Extraction line is mainly made up following systems:

Oil Extraction system: for extracting oil from pressed cake to get Miscella which is mixture of Oil and Hexane;

Wet Meal Desolventizing System: for removing Solvent from Wet Meal as well as to toast and dry Meal for getting proper finished Meal Product qualified for animal feed;

Miscella Evaporation System: for evaporating and separating Hexane out from Miscella under negative pressure;

Oil Stripping System: for thoroughly removing residual Solvent to produce standard Crude Oil;

Solvent Condensing System: for recovering and circulating use of Hexane;

Paraffin Oil Recovering System: further recovering residual Hexane gas remains in vent air by means of Paraffin Oil to reduce Solvent consumption;

Oil Refining Advantage:

1) After refining the impurity of oil must be less than 0.2% ;

2) Recycling system save power and money ;

3) Lower oil waste.

4) No solid sediment in low temperature.

Start soybean oil production line – factory price oil processing equipment for soybean oil making: buy soybean oil making machine from oil mill equipment manufacturer or supplier at factory price, get FREE technical instruction of soybean oil production process and business plan to set up soybean oil mill plant project in Mexico, Panama, Pakistan, Thailand, Kazakhstan, etc., at low cost.