Sunflower oil is extracted from sunflower seeds. It’s a highly nutritious edible oil, rich in nutrients such as linoleic acid and vitamin E. It benefits the immune system, can prevent cancer, and due to its antioxidant and anti-inflammatory properties, it can also help prevent asthma. As a result, sunflower seed oil finds extensive commercial and household applications, especially in the food industry.

Sunflower Oil Press Machine

Type 1: Screw Sunflower Oil Press Machine

| Machine Advantages:

* Automatic |

|

Capacity:1t/d, 3t/d, 5t/d, 8t/d, 10t/d, 10-20t/d, 30t/d

Suitable for:sunflower seed, peanuts, flax seed, sesame, rapeseed, cottonseed, soybean and more than 30 kinds of oil seeds

Type 2: Sunflower Oil Press Machine With Filter

| Machine Advantages:

* Multipurpose |

|

Capacity: 2t/d, 3t/d,4t/d, 5t/d, 6t/d, 8-10t/d

Suitable for:sunflower seed, peanuts, flax seed, sesame, rapeseed, cottonseed, soybean and more than 30 kinds of oil seeds

Type 3: Large Sunflower Oil Press Machine

| Machine Advantages:

* Automatic |

|

Capacity:9-10t/d, 10-50t/d, 50-80t/d, 80-150t/d, 150-300t/d,300t/d

Suitable for:sunflower seed, peanuts, flax seed, sesame, rapeseed, cottonseed, soybean and more than 30 kinds of oil seeds

Sunflower Oil Production Line

Small Scale Sunflower Oil Pressing Line

- Production Output: 1-20ton/day

- Main Equipment: Cleaning/screening machine, seeds cooker, oil expeller, oil filter press and conveyors.

This sunflower oil manufacturing unit is effective, automated and affordable which makes it ideal choice for small scale sunflower oil factory. It is capable of continuous cooking oil processing plant.

Advantages of small scale sunflower seed oil press machine

- Lower price and more acceptable: although the price of small sunflower seed making machine will vary from the functional configuration and the machines capacity, they are generally cheaper that large-scale oil press machine hence more acceptable to a majority of customers.

- Fewer requirements for operation: Both large and small oil pressing machines performs all the function necessary for edible oil production. However, small scale sunflower seed oil press machine are more convenient because they require fewer operation conditions like small space of operation.

- Less labor requirement: Most small scale oil pressing machines only requires 2 to 3 person to run the whole line

- Functional: small-scale oils pressing machines for sunflower seed are capable of handling both hot and cold pressing, other than that, they can also be used to press other types of oil seeds.

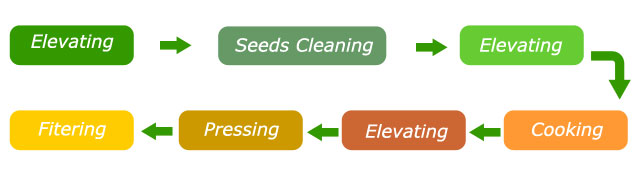

Flow Chart of the Sunflower Oil Pressing Line

Elevating – Seed Cleaning – Elevating – Cooking – Elevating – Pressing – Filtering

Or you can choose an integrated oil press machine to press and filtrate oil at one time.

Features of the Sunflower Oil Pressing Line

★ Easier to operate, easier to install and commissioning.

★ Need small investment, fewer land space, but with the complete function of the production.

★ Wide application that can make many other kinds of vegetable seeds and nuts, such as rapeseeds, cotton seeds, sunflower seeds, corn germ, palm kernel, sesame seeds and so on.

★ Need fewer labor than the single machines, only 2~3 persons can run the whole line

★ The semi-continuous can avoid the unstable material feeding caused by manual and can make the worker safety more under the higher temperature working situation.

Large Scale Sunflower Oil Production Line

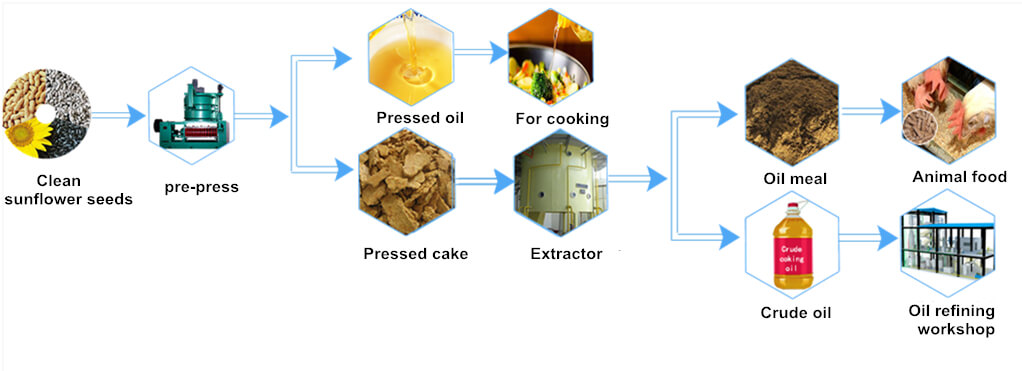

Large scale sunflower oil production line consists of sunflower seeds pretreatment and pre-pressing plant, sunflower oil solvent extraction plant and sunflower oil refinery plant.

In the whole sunflower oil production line, sunflower seeds should be shelled, cleaned, cooked and pressed. If you want high oil yield, sunflower oil solvent extraction plant is necessary. Through sunflower oil solvent extraction plant, the oil residue will be less than 1%, and the meal will be more suitable for animal feed.

If you want standard sunflower oil, which can be sold in supermarket, you should have sunflower oil refinery plant. The final production, sunflower oil, is able to meet the first grade oil standard after the whole sunflower oil production line.

1. Sunflower seeds preparation and oil pre-pressing line

Sunflower seeds preparation is through a series of machines to deal with sunflower seeds in order to adjust the shape, temperature and humidity of sunflower seeds to extract sunflower oil easily.

Sunflower oil pre-pressing machine can extract about a half sunflower oil from sunflower seeds, then sunflower seeds cakes will be sent to the next part–sunflower oil solvent extraction line.

2. Sunflower oil solvent extraction line

Generally, the capacity more than 30 tons per day, the sunflower oil solvent extraction line is recommended to add into the whole sunflower oil production line. Sunflower oil solvent extraction line uses n-hexane to dissolve sunflower oil from sunflower seeds cakes. Then, through evaporating and stripping, the n-hexane is evaporated from the mixed oil, to get sunflower oil.

The biggest advantage of sunflower oil solvent extraction line is the high oil yield. Because the sunflower seeds cake from sunflower oil solvent extraction line only contains less than 1% residual oil. It is also the biggest advantage of large sunflower oil production factory.

3. Sunflower oil refining line

In big scale sunflower oil production line, the sunflower oil refining line is usually automatic and continuous. Full-continuous sunflower oil refining machine contains four main processes: Degumming & Deacidification — Decolorization — Deodorization.

The sunflower oil refining line is mainly to remove the impurities from crude sunflower oil, to get refined sunflower oil, which is with light and bright colors, good flavor. But the last step — sunflower oil dewaxing is important for the customers who want to sell their refined sunflower oil in the supermarket.

4. Sunflower oil dewaxing line

Sunflower oil dewaxing line is to remove wax content in sunflower oil. High wax content will influence the flavor of sunflower oil. Through heating, cooling & crystallization, and filtration three steps finish the dewaxing process of sunflower oil.

A complete sunflower oil production line also contains sunflower oil packing and filling line. There are also a series of machines in sunflower oil packing and filling line. Such as Blow moulding machine, Unscrambler machine, Filling machine, Screw cap machine and Labeling machine.