Sunflower Oil Extraction Process, Methods – A Full Guide

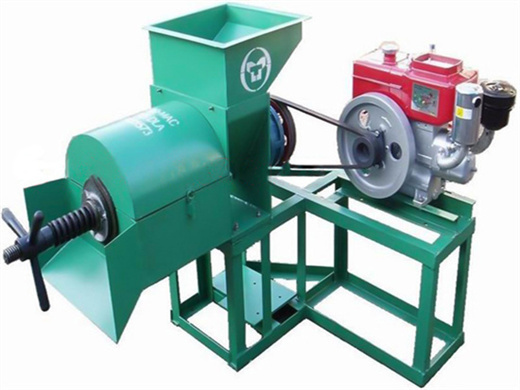

- Type: sunflower oil processing equipment

- Usage/Application: sunflower

- Egg capacity (pcs): 3168

- Voltage: 220V-240V AC 50/60HZ

- Weight: 175kg, 175kg

- Dimension (L*W) *H): 1790*850*1680mm

- Power (W): 600 w

- Country: afghanistan

Cost of Sunflower oil extraction machine: Cost of automatic Sunflower oil extraction machine approximately, Rs 1.45 Lakh/Piece. Benefits of Sunflower oil. May enhance oral health. Sunflower oil is extremely useful for oil pulling. Sunflower oil reduces plaque-related gingivitis.

From Seed to Oil: Unveiling the Sunflower Oil Extraction Process

- Type: sunflower oil processing machine

- Voltage: 380 V

- Power (W): mill to make cooking oil

- Certification: CE and ISO

- Weight: mill to make cooking oil

- Dimension (L*W*H)): mill to make cooking oil

Here are the ten most frequently asked questions (FAQs) about the sunflower oil extraction process, quality, and applications, along with their answers: 1. What is the best extraction method for sunflower oil? Mechanical pressing and solvent extraction are the most common methods used for sunflower oil extraction.

Sunflower is treasure all over. Sunflower seed kernel has high oil content around 45%~55% and can be used for oil extraction. Sunflower seed oil is called "advanced nutrition" or "health oil" at home and abroad and is a best-selling product in the international market.

A Step-by-Step Guide on How Sunflower Oil is Made

- Usage: sunflower oil

- Production capacity: 10 to 500 tpd cooking oil production

- Voltage: 220V /380 V/440 V

- Weight: 850 KG

- Dimension (L*W*H): 5432*2636*2345

- Power (W): depends on capacity

Solvent extraction is the part of the sunflower oil making process in which almost every last drop of oil is extracted from the sunflower seeds. Hexane is the most widely used solvent for this. The process begins with the pouring of hexane over the leftover cake from expeller pressing.

Cooking Oil: Sunflower oil is known for its premium characteristics such as light colour, bland flavour, rich unsaturated fatty acids, low linoleic acid and high smoke point. From improving heart health and keeping the skin glowing from within to boosting energy and strengthening the immune system, the goodness of sunflower oil can help take

HOW IS SUNFLOWER OIL EXTRACTED? - Grainvest

- Type: cooking oil extraction machine

- Production capacity: 100TPD

- Dimension (length x width x height): 420mm x 180mm x 280mm

- Voltage: AC220V, AC220V

- Weight: 9.2 kg

- Main components: motor, olive oil processing machine

Sunflower oil production has the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extraction of crude oil from these seeds and then further refining the oil obtained before packaging. A volatile hydrocarbon like hexane is used as a solvent to extract the oil. Cleaning; De-hulling; Grinding; Pressing

The purpose of grinding is to increase the surface area to be heated during extraction. Sunflower Oil Extraction; The heated sunflower seeds meal is continuously added to the sunflower oil making machine that has slotted barrel at highly progressing pressure from 69000 to 200000 kilopascals. The oil is squeezed out and recovered through the

How Is Sunflower Oil Made? (The Step-by-Step Process)

- Raw Material: sunflower

- Production capacity: 50-1000 kg/h

- Dimension (L*W*H): 2120*1200*1500

- Voltage: 220V/380V

- Weight: 450 KG

- Main components: motor, pressure vessel, pump, PLC, others, Gear, bearing, motor, gearbox, cooking oil processing machine

Overall, making sunflower oil is a complex process that involves several steps. The quality of the oil depends on the quality of the seeds and the method of extraction used. Cold-pressed sunflower oil is generally regarded as the highest quality, as it retains all of its beneficial compounds.

Following this, the obtained sunflower oil is refined to remove impurities. The solvent extraction process is the most widely used treatment method in the world today for the extraction of sunflower oil. Benefits: Solvent extraction allows for a significant yield, potentially reaching up to 97%.