Peanuts Mechanical Methods of Oil Extraction from

- Type: peanut oil plant

- Usage/Application: peanut, groundnut

- Production capacity: 15-20 kg per hour small oil press

- Voltage: 220v 50hz single phase

- Main components: motor, pump, gear, bearing, gearbox

- Weight: 126 KG

- Dimension (L*W*H): 700* 700*900 mm

- Country: zimbabwe

techniques for oil extraction from peanuts are grouped into three main sections: extrusion and screw pressing, cold pressing, and hydraulic pressing. oil extraction mechanical methods defatting peanuts defatted peanuts peanut proteins texturization MEPSI 1. Introduction Peanut, or

Peanut Oil Processing Technology - ScienceDirect

- Type: peanut oil processing machine

- Outgoing video inspection: provided

- Machinery test report: not available

- Weight: 0.77 kg

- Main components: filter

- Main components marketing warranty: 1 year

The conditioned peanut kernels are transported by a conveyor to the twin-screw press for cold pressing; the cold-pressed crude oil and cold-pressed peanut meal with low denaturation will be obtained. After the cold-pressed crude oil is filtered with frame filter, product oil is obtained, which will be packaged by a filling machine to form cold

This review elucidates the methods used for extracting peanut oil, including mechanical and chemical processes that have been combined with biological or physical pre-treatment techniques.

PROCESSING OF PEANUT OIL - NIFTEM

- Usage: peanut oil

- Production capacity: 5TPD-100TPD

- Voltage: 220V/380V

- Main components: Motor

- Weight: 140 KG

- Dimension (L*W*H): 1500*680*1400mm

• The peanut oil market size has an immense potential to grow by approximately USD 1.9 billion during 2020-2024. • The growth momentum will probably accelerate progressing at a CAGR of 3% during the forecast period. • The report on peanut oil market provides a wholistic approach and analysis

To commercially extract cold-pressed peanut oil, a twin-screw press is used, and the pressing is performed at specific temperatures that do not exceed 60 °C. The oil yield was not evaluated in this study, but the researchers were very interested in utilizing the by-product of this extraction (i.e., the meal), knowing that 70 kg of PDPM was

(PDF) A comparative study of various oil extraction

- Type: cooking oil extraction machine

- Production capacity: 100% vegetable oil distillation

- Power (W): 5.5-22 KW

- Voltage:220V/380V/440V

- Dimension (L*W*H)):48m*12M*15M(30TPD)

- Weight:30 tons

extraction of edible oils from plant sources is hexane. This is due to its low boilin g temperature and easy rec ov - ery and since most oils are sol uble in hexane.

processed` but in groundnut oil extraction about 10% by weight of husk should be added back to the nuts to allow oil to escape more freely from the press. Coconut is dehusked and split by skilled operators as this is faster than the available small-scale machines. Most nuts need grinding before oil extraction to increase the yield of oil.

Groundnut Oil Manufacturing Process With Flowchart - Goyum

- Raw Material: peanut

- Production capacity: 50~140 ton/day

- Dimension (L*W*H): Depends

- Voltage: 380V/440V

- Weight: 24500 KG

- Warranty: One year warranty against manufacturing defect.

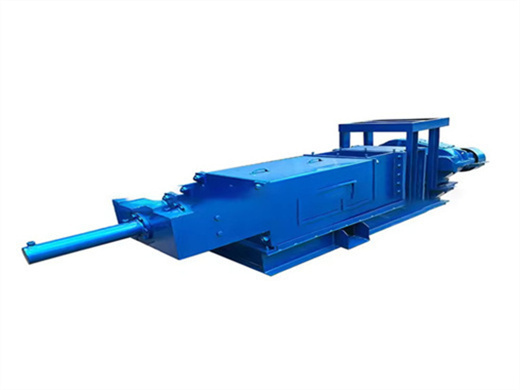

Step 4: Pressing. The peanuts are transfer by conveyor and fed through the hopper of screw press machine. Continuous transport of material by the screw shaft causes pressure to increase to a level needed, which increases friction inside the screw press and generates heat which lowers viscosity of the oil in the crushed seeds thereby increasing the oil flow rate.

Groundnuts solvent extraction process. Generally, the Groundnut or peanut solvent extraction is a procedure which involves extracting oil from oil-bearing materials by treating it with a low boiler solvent as opposed to extracting the oils by mechanical pressing methods that are expellers, hydraulic presses, etc.