Palm Oil Machine - Palm Oil Production Line

- Type: palm oil production line machine

- Usage/Application: palm fruit, palm kernel

- Production capacity: 98%

- Voltage: 380V, depends on capacity

- Weight: depends on capacity

- Dimension (L*W*H): depends on capacity, depends on capacity

- Power (W): depends on capacity, depends on capacity

- Country: afghanistan

Hongde Oil Machinery is leading professional manufacture and supplier of palm oil production line equipment includes palm fruit oil press, palm kernel oil extraction machine, CPO Refinery, and palm oil fractionation plant. Our team offer turnkey production solution for complete palm oil processing project with competitive cost!

Palm Oil Processing Production Line

- Type: palm oil processing machine

- Surface Treatment: Factory Finished

- Alloy: Non-Alloy

- Component: Aluminum

- Delivery time: Future goods: 25-35 days, ready products: 7-10 days

- Tolerance: 1%

Sterilization as the first step in palm fruit pressing is critical to the quality of the final production-- palm oil. The purpose of sterilization process is, inactivate the activity of lipase and prevent the rise of free fatty acids; make the palm fruit easier to fall off from the fruit bunch; and soften the peel and make the oil easier to separate out.

Palm oil production line. Hongde Oil Machinery is a leading company in the field of palm oil pressing and palm kernel oil processing and equipment, we can provide completely set of 5-120tph palm oil production line. Our company offers a range of products and services for the palm oil extraction, palm kernel oil extraction, crude palm oil

Hongde palm oil machine / FFB oil mill - Palm Oil Production Line

- Usage: palm oil

- Voltage: 220V/380V/440V

- Power (W): 22kw

- Certification: ISO CE

- Weight: 30 tons

- Dimension (L*W*H): 48m*12M*15M(30TPD)

[rev_slider alias=”slider3″ slidertitle=”Slider 2″][/rev_slider] COMPLETE PALM OIL PRODUCTION LINEPalm Oil Engineering Project Specialist PALM OIL MILL PLANT Hongde palm machinery provides a range of palm oil making machines to extract oil from fresh fruit bunches of oil palm. The following is the typical palm oil manufacturing process which might be useful for new investors of […]

The Batch type is the ideal choice for small-sized palm oil production (1-20TPD), while the Semi-continuous Refinery plants are the best choices for middle-large size production lines (20-50TPD), a fully continuous refinery line(50-600TPD) is most used in large palm oil production plants.

palm oil processing equipment/palm oil refinery plant/palm

- Type: cooking oil extraction machine

- Production capacity: 200 kg/h-2000 kg/h-100%

- Dimension (L * W*H): Depends on capacity

- Voltage: 220 V/380 V/440 V

- Weight: 560 KG

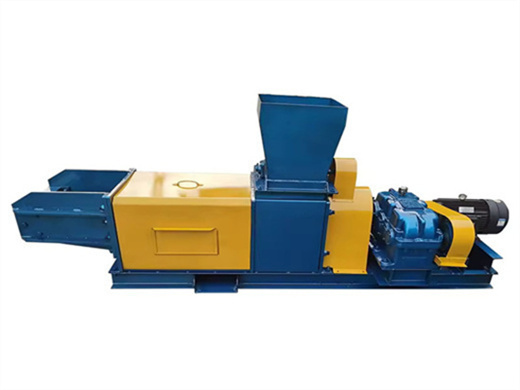

- Main components: motor, pressure vessel, gear, motor, gearbox

ABOUT Hongde GROUP. Hongde Group is a large-sizd joint-equity enterprise specializing in the production of edible oil mechanical equipment. It integrates scientific research, manufacturing and sales, and provides complete set of equipment for palm oil and palm kernel oil production.

Hello, sir. We can supply compete palm kernel oil production plant from 1tpd to 400 tpd. A 10 tons per day palm kernel oil production line will cost about is $ 60,000 around. The required equipment is palm kernel crushing and separating machine, palm kernel oil extraction machine, oil filter machine, palm kernel oil refining machine, etc

Palm Oil Mill Plant Production Line - Hongde OIL MACHINE

- Raw Material: palm

- Production capacity: 1-500T/D

- Dimension (L*W*H): Up to the capacity of oil refinery

- Voltage: 380v or 220v

- Weight: 1100 KG

- Warranty: 2 years, 12 months

We can offer you a whole line of palm oil pretreatment equipment, palm oil extraction machines, and palm oil refinery machines, and build a palm oil turnkey project from A to Z for you. And we sell single machines too, palm fruit oil pressing machines, palm fruit crushing machines, palm fruit oil fraction machines and so on. GET A QUOTE

Palm oil mill process includes 6 parts: Palm fruits receiving, sterilizing, threshing, digesting and pressing, crude oil clarifying and palm kernel recovery. SterilizationThe main purpose of sterilization is to destroy the lipase in the pulp, so as to prevent the free fatty acid content in the oil from increasing. We offer both horizontal and vertical […]