(PDF) Defatting and Defatted Peanuts: A Critical Review on

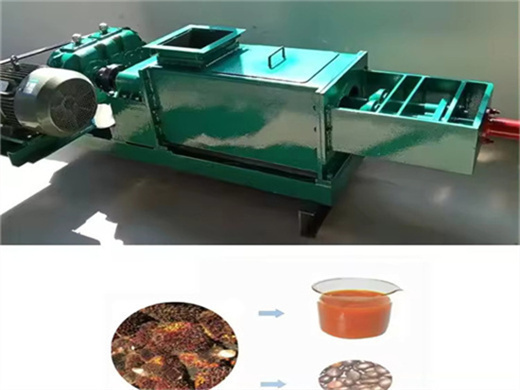

- Type: peanut oil extraction machine

- Usage/Application: peanut, groundnut

- Production capacity: 250-300 KG/H

- Voltage: 380V

- Weight: 2200kg

- Dimension (L*W*H): 2000x1200x2500mm

- Power (W ): 3KW

- Country: zimbabwe

This review elucidates the methods used for extracting peanut oil, including mechanical and chemical processes that have been combined with biological or physical pre-treatment techniques

Peanuts Mechanical Methods of Oil Extraction from

- Type: peanut oil refinery machine

- Production capacity: 5TPD-100TPD

- Voltage: 380V/50HZ/Three-phase

- Raw material: cotton seeds, sunflower, soybeans, rapeseed

- Weight: 4500 kg

- Dimension (L*W*H): 2900*1120*1850mm

techniques for oil extraction from peanuts are grouped into three main sections: extrusion and screw pressing, cold pressing, and hydraulic pressing. oil extraction mechanical methods defatting peanuts defatted peanuts peanut proteins texturization MEPSI 1. Introduction Peanut, or

A study carried out in 2019 by Suri et al. examined how peanut oil quality characteristics were affected by a combination of dry air roasting and mechanical extraction using screw pressing . The researchers found that optimal conditions for air roasting were 180 °C for 10 min, followed by cooling at room temperature.

Peanut Oil Processing Technology - ScienceDirect

- Usage: peanut oil

- Voltage: 380v

- Dimension (L*W*H): 1580*430*1190mm

- Oil type: Various oil materials

- Main components : Engine

- Weight: 80KG

It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology. At the end of the chapter, it discusses the peanut oil production line and the relevant key equipment.

Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method. According to mechanical pressing technology, you can divide the peanut oil production process into three phases. These are peanuts preparation, pressing and crude oil refining.

Groundnut Oil Making Process (Peanut), Business Plan

- Type: cooking oil refining machine

- Production capacity: 5T~10T/D

- Power ( W): according to capacity

- Voltage:220V/380V

- Dimension (L*W*H)):5432*2636*2345

- Weight:2000kg

Therefore, it is essential to equip the peanut oil production plant with professional edible oil refinery equipment to get them off and obtain the refined high-quality peanut oil. Groundnut Oil Processing Flowchart. Cost of Groundnut oil extraction machine: Generally, the cost of Groundnut oil extraction machine will be approximately Rs 1.8

Peanuts, being crucial crops of global importance, have gained widespread recognition for their versatility and nutritional value. In addition to direct consumption, either with or without treatment, peanuts can be the subject of diverse applications focusing mainly on two distinct objectives: oil extraction and defatting processes. As a result of the first process, a solid matrix is generated

What is the basic principle of peanut oil solvent extraction?

- Raw Material: peanut

- Production capacity: 400~600 kg/h

- Power (W): 18.5 kW

- Voltage: 220V/380V

- Dimension (L*W*H): 1500*1600*2500mm

- Weight: 2000kg

The solvent extraction of peanut oil is a process of extracting peanut oil with n-hexane as extraction solvent. The process consists of four systems: solvent extraction system, wet meal desolventizing system, mixed oil evaporation system, and solvent condensation recovery system. Here I will introduce how these systems works.

The results showed that peanut oil and protein extraction rates peaked at 90 °C, 92.21%, and 77.02%, respectively. The roasting temperature did not change OBE composition but affected its stability.