100-200Tpd Cotton Seed Crude Oil Refining Machine in bangladesh

- Type: cottonseed seed oil extraction machine

- Usage/Application: cottonseed

- Production capacity: 7-10T/24 hours

- Voltage: 380V/50HZ

- Color: Optional

- Weight: 5000kg

- Dimension (L*W*H): 2900*1850*3240 mm

- Country: bangladesh

bangladesh’s Downstream Industry Sees String of New Investments If current feasibility studies are favorable, the project could connect up to 125 billion barrels of crude oil and 1.6 trillion cubic feet of natural gas reserves with the global economy by 2030, positioning bangladesh at the center of a major regional downstream hub.

Cottonseed Oil Mill / Oil Extraction Plant Manufacturers

- Type: cottonseed oil processing machine

- Product key word: sunflower seed screw oil press

- Solvent: n-hexane

- Dimension (L*W*H): according to capacity</td

- Extractor type: rotocel extractor

- Voltage: 380V or 440V

Undecorticated Cottonseed obtained after Delinting process can be used as a raw material for Cottonseed Oil Extraction Plant. Cottonseed contains 18 – 20 % oil content. After a single stage pressing, about 6 – 7 % residual oil is left in the cottonseed meal which is an excellent source of Cattle Feed. The working principle of the cotton

Our oil extraction machines are engineered with the latest innovations to ensure your cottonseed oil production meets the industry standards and you gain a competitive edge. Global Reach With a robust global presence, we serve clients worldwide with timely delivery, comprehensive support, and service excellence, regardless of your location.

Cottonseed Oil Mill Plant

- Usage: cottonseed oil

- Voltage: 380v/440v or local voltage

- Power (W): According to the capacity of daily cooking oil extraction machine price

- Certification: ISO9001

- Weight: According to the capacity of cooking oil extraction machine price

- Dimension (L*W*H): 1200*400*900mm3

Cottonseed Oil Pressing / Expelling (by using Mechanical Screw type Oil Press); Cottonseeds can be pre-pressed before they get sent directly to the refinery plant. To handle 20 tons of cottonseed per day, the solvent extraction method is used with cottonseed oil prepress to take parts of the oil.

Features of Cottonseed Oil Processing Plant. 1. Cottonseed oil mill plant has high automation degree, continuous operation, saving labor. 2. The pre-pressed cake has low residual oil rate and is easy for solvent penetration. 3. Cottonseed oil extraction plant has multiple oil extractors for selection and advanced mineral oil system. 4.

Cottonseed Oil Press Oil Extraction Oil Refinery Plant

- Type: cooking oil extraction machine

- Production capacity: 1-2000TPD

- Power (W): Depends

- Voltage: Local voltage

- Dimension (L*W*H): 2000x1400x1850mm

- Weight: 30tons

1. cottonseed oil press→ cottonseed oil refinery 2. cottonseed oil pre-press→ cottonseed oil extraction→cottonseed oil refinery. Normally for input capacity more than 20 tons per day, it's better to adopt the second Cottonseed Oil Processing Plant processing method with better cost performance. Here we will introduce you the second method.

This integrated cottonseed oil expeller machine is ideal choice for movable oil making store, small oil factory, small oil production lines and more. We have many oil pressing plant projects that was set up with this integrated oil extraction expeller, like 10 tons per day sunflower oil production plant in Moldova .

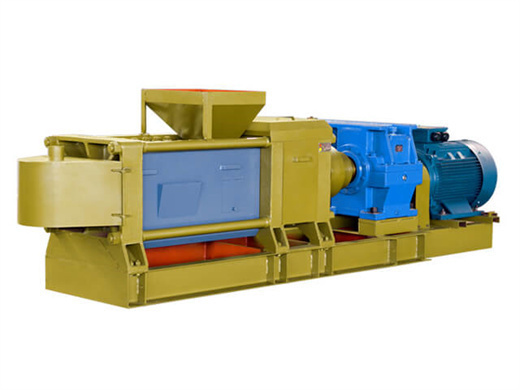

Serviceable 100-200TPD cotton seed cooking oil pressing

- Raw Material: cottonseed oil

- Production capacity: 1-100T/DAY

- Dimension (L*W*H): 2320*700*780mm

- Voltage: 220V/380V

- Weight: 700 KG

- Main components: Engine oil

Buy Serviceable 100-200TPD cotton seed cooking oil pressing machinery / pre-pressing extraction production for sale with CE approved from Expeller Pressed Machine,1-20TPD Small Scale Oil Refining Line Distributor online Service suppliers.

Brief Overview of Cottonseed Oil Production Line. 1. The cottonseed oil production process is advanced, with full consideration of low cost, energy saving, environmental protection, and thermal energy recovery and reuse. 2. The process can achieve fully automated control. 3.