Sunflower oil processing plant

- Type: sunflower oil processing plant

- Usage/Application: sunflower

- Production capacity: 5TPD

- Voltage: 220V/380V

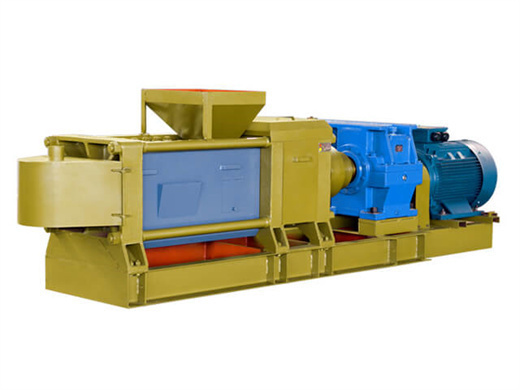

- Main components: motor, pump, gear, Motor, Gearbox

- Weight: 950 kg

- Dimension (length x width x height): 900*850*1550mm

- Country: nairobi

Modern full-cycle sunflower processing production that meets international standards. The plant has everything required for the efficient work: a shop for sunflower processing and vegetable oils production, warehouses for storing raw materials, cake, oil storage tanks, an elevator for 125 thousand tons of grain, an accredited laboratory, qualified personnel.

Sunflower seed oil production manufacturing process analysis

- Type: sunflower oil processing machine

- Production capacity: 35-550kg/h hydraulic cooking oil press

- Voltage: 380V or local voltage

- Weight: 1000KG

- Dimension (L*W*H): 900*850*1550mm

- Power (W): according to the capacity of the hydraulic cooking oil press

4. Use sunflower oil pre-pressing machine to obtain a part of sunflower oil form sunflower seeds. Sunflower oil solvent extraction plant: Machines used in sunflower oil solvent extraction plant. 1. Sunflower cakes are sent into extractor, then soaked in solvent, at last the mixed oil will flow out of the extractor. 2.

IMARC Group’s report titled “Sunflower Oil Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a sunflower oil manufacturing plant. It covers a comprehensive market overview to micro-level information such as

Sunflower Oil Production Plant Process Flowchart - GOYUM GROUP

- Usage: sunflower oil

- Customized: Customized

- Equipment Material: Carbon Steel

- Technology: Solvent

- MOQ: 1

- Warranty: 12 months

Cooking Oil: Sunflower oil is known for its premium characteristics such as light colour, bland flavour, rich unsaturated fatty acids, low linoleic acid and high smoke point. From improving heart health and keeping the skin glowing from within to boosting energy and strengthening the immune system, the goodness of sunflower oil can help take

The oilseeds are prepared and pressed to get the maximum amount of sunflower oil with the minimum amount of effort. KMEC is a leading company in sunflower oil processing. We are able to design a complete sunflower oil plant and offer quality sunflower oil processing machinery. We are your trusted sunflower oil processing plant manufacturer in

Sunflower Oil Production Line

- Type: cooking oil extraction machine

- Voltage: 220V/380V

- Dimension (L*W*H): standard

- Power (W): standard

- Weight : standard

- Certification: CE ISO

The oil is extracted directly from the sunflower seeds by a screw type oil press machine. Sunflower seeds are cold-pressed (or hot pressed) at a certain temperatures, and the protein-rich cake that remains after the seeds are processed into oil is used as animal feed, retaining 99% of the nutrients in sunflower oil without the use of chemical solvents.

Sunflower oil is a mixture mostly of the polyunsaturated fat, linoleic acid (59% of total), and the monounsaturated fat, oleic acid (30% of total). In sunflower oil plant breeding and manufacturing, four types of processed oil containing different amounts of the main fatty acids are produced.

How is Sunflower Oil Processed?

- Raw Material: sunflower

- Production capacity: 100TPD

- Dimension (L*W*H): customized

- Voltage: 380V/50HZ 3 phases (customize according to your local power)

- Weight: 1000 KG

- Main components warranty: More than 5 years

Sunflower oil processing involves many process that will decide the equipment and machinery for a sunflower oil processing plant. For small scale sunflower oil processing line, the equipment may be relatively simple and easy to operate. Of course, the investment cost for small scale oil factory is low but the profits is considerable. If you are

Solvent extraction is the part of the sunflower oil making process in which almost every last drop of oil is extracted from the sunflower seeds. Hexane is the most widely used solvent for this. The process begins with the pouring of hexane over the leftover cake from expeller pressing.