Soybean Oil Process Machine

- Type: soybean oil machine

- Usage/Application: soybean

- Production capacity: 1-100T/D

- Voltage:380V/440v

- Weight: depends on capacity

- Dimension (L*W*H): depends on capacity

- Power (W) : 20-50KW

- Country: uganda

It undergoes filtration to remove larger particles before moving to the refining stage. Types of Soybean Oil Process Machines: 1. Soybean Oil Press Machines: - These are mechanical screw presses used for squeezing oil from soybeans. They are used in small and medium-scale processing plants. They are easy to operate and offer moderate oil yields. 2.

Equipment to Start a Small Scale Soya

- Type: soybean oil processing machine

- Production capacity: 1-500T/D

- Voltage:220V/380V/440V

- Weight:1050KG

- Dimension(L*W*H):1610x615x1260mm

- Power (W): According to capacity

The cost of land for a small scale soyabean oil mill will not be very high. You can have cheaper land if you buy/rent it in a rural area. The main thing that will consume most of the budget will be soybean oil mill machines. Generally, the cost of establishing a mini/small scale small scale soybean oil plant ranges from $5,500 to $35,000.

The oil press residue is about five to seven percent. The final user after processing by oil press can get crude soybean oil as well as soybean cakes. These soybean cakes can be used for making the feed of animal. (Related project: 25TPD Small Scale Soybean Oil Mill Plant in Ghana >>) Soybean Oil - Solvent Extraction Machine

How to Start Mini Soybean Oil Mill Plant | 1~30 Tons/Day

- Usage: soybean oil

- Production capacity: 60%

- Voltage: 220V/380v

- Main components: Motor

- Weight: 800-2000 KG

- Dimension (L*W*H): 1200*780*1100 mm

Our mini soybean oil mill can perfectly meet all your expectations about soybean oil manufacturing. It just connects necessary soybean oil processing machine together by conveyors to form continuous and automatic soybean oil production. The common capacity of our mini soybean oil mill is about 1~30 tons per day. Estimates of the total cost

Squeezing: The soybeans that have been processed through the previous steps are transported to the soybean oil press machine for compression, and soybean oil can be obtained. The above-mentioned soybean oil production process and the equipment used in the steps are the standard version of the soybean oil production line. According to your needs

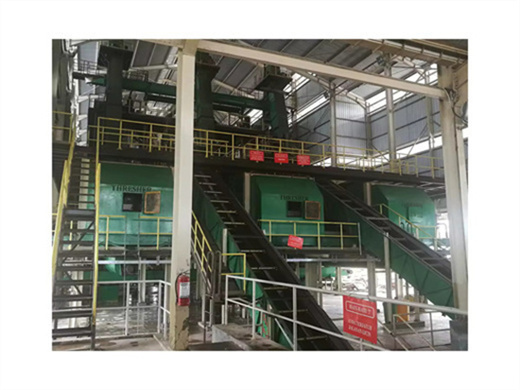

Soybean Oil Mill / Oil Extraction Plant Manufacturers

- Type: cooking oil extraction machine

- Main components: PLC, motor, bearing, gearbox, motor, pressure vessel, gear, pump

- Power : 226 kw

- Voltage: 380V/50Hz

- Weight: 5 KG

- Dimension (L *W*H): 35*3*3m

Soybean Oil Extraction Process. Soybean oil extraction plant require a series of automated processing steps. Normally, the basic process of a soybean oil production plant is seed cleaning, destoning, oil pressing, Cake / Meal Conditioning, oil filtration. Every process has the respective soybean oil processing equipment to fulfill its functions.

The above are small-scale soybean oil production line. If the small-scale soybean oil mill plant has a processing capacity of less than 20 tons, it is recommended to use the above steps. If the processing capacity is large, it is recommended to use more complete soybean oil production machines to obtain more and cleaner soybean oil.

Small scale soybean oil extraction machine

- Raw Material: soybean

- Production capacity: high

- Dimension (L*W*H): 1700*1250*1650 mm

- Voltage: 380 V

- Weight: 760 KG

- Main components: motor, pressure vessel, Pump, gear, bearing, motor, gearbox

Screw soybean oil press machine with capacity 200-300kg/h. 3.Soybean oil filter machine: This soybean oil filter machine is to remove the impurities from crude soybean oil, so you can get clean soybean oil. Soybean oil filter machine is the major equipment in soybean oil extraction machine. Small scale soybean oil filter press machine

Generally, a small scale soybean oil mill that adopts simple oil extraction process and equipment will cost about $7,000 ~ $10,000. However, the exact cost may be varied from the capacity, equipment and process. Firstly, it is very important to completely understand the right and efficient soybean oil manufacturing process. Generally, the