Steps of Cottonseed Oil Processing Process - Oil Mill Machinery

- Type: cottonseed oil line

- Usage/Application: cottonseed

- purpose: cooking

- Description: Semi-continuous

- trodor: no unpleasant smell

- color: fresh bright

- Material: Stainless steel

- Country: south africa

Within the cottonseed oil processing plant, oils extracted from cottonseed must be refined to remove gossypol, a naturally occurring toxin that protects the cotton plant from insect damage. Cottonseed meal is a good source of protein. It is the byproduct remaining after cotton is ginned and the seeds crushed and the oil extracted.

Title: -PROJECT PROPOSAL ON EDIBLE OIL PROCESING COMPANY

- Type: cottonseed oil refinery machine

- Voltage: According to customer demand

- Power (W) : According to project

- Certification: ISO9001-2008, CE, BV

- Weight: According to customer demand

- Dimension(L*W*H): According to project

The following summarizes prices used: Table: 3.2 Product prices Unit of Measure Refined oil – south africa seed -Cotton Seed Oil cake – south africa seed -Cotton seed Price per unit product Litres 63 Litres 62 Tons 5000 Tons 4500 3.5 Price Assessment The saleable items of the project are refined oil which is the principal product and oil cake which come

Cottonseed oil contains a large amount of essential fatty acids, among which linoleic acid has the highest content, which can reach 44.0-55.0%. In addition, cottonseed oil also contains 21.6%-24.8% palmitic acid, 1.9-2.4% stearic acid, 18%-30.7% oleic acid, and 0-0.1% arachidic acid. Cottonseed oil can be used for cooking and consumption.

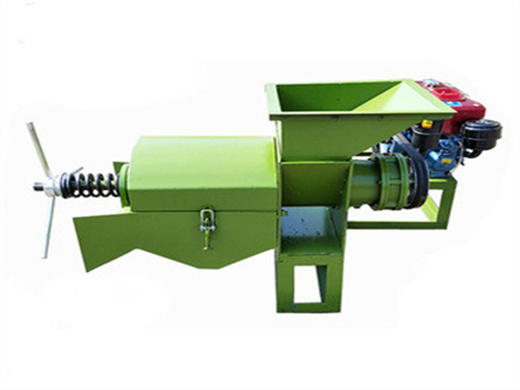

Cotton Seed Processing, Oil Extraction & Refining Plant

- Usage: cottonseed oil

- Production capacity: 45 kg per hour / 1080 kg per day

- Voltage: 220V/240V

- Warranty: 2 years

- Weight: 67kg

- Dimension (L*W) *H): 840* 240*540

Cottonseed could either be processed by the traditional crude method of crushing seed without Delinting in un-decorticated form or by scientific processing used for Cotton Seed Processing, which involves removal of De-linters, decortication, separation of hull, expelling, solvent extraction and refining of oil. Scientific processing of Cotton

Cottonseed oil is extracted from the seeds of cotton plants. Refined cotton seed oil is edible. India, China, Pakistan, USA and Brazil are among the top producers of cotton seed oil in the world. Let us now know about the various aspects of cottonseed oil plant - it's manufacturing process, world market status and other features.

A Complete Guide to Cottonseed Oil Processing - Anderson

- Type: cooking oil refining machine

- Product processing Cultivation Use: Cooking

- Purity (%): 100

- Packaging: Glass bottle, bulk, Drum, Plastic bottle

- Volume (L): 5

- Grade: amazing

What’s Inside the eBook In this guide to cottonseed oil processing, we’ll examine the history of cottonseed production, various processing methods, and diverse product applications as we explore the global potential of this plant. Once they have been delinted and dehulled, the small black cottonseeds contain about 30% fat and the oil is used in…

The extraction process ensures that the oil content in seeds is separated efficiently and can be further processed for consumption or other uses. Why is refining seed oils considered a necessary step? Refining seed oils is essential to remove impurities, enhance flavor, and extend shelf life.

Title Project Proposal ON Edible OIL PRO - St. Mary’s

- Raw Material: cottonseed oil

- Production capacity: 100TPD

- Dimension (L*W*H): 540*250*360 mm

- Voltage: 220 V

- Weight: 11 kg

- Main components: Motor

The new oil processing plant will have a capacity to process 20 tons of two kinds of oil seeds including south africa seed and cotton seed. The technology selected offers greater opportunity to produce edible oils from any of the given oil seeds variety based on the prevailing market situation.

Cottonseed oil production is rife with challenges, though. The fluffy white fibers and abrasive hulls can be difficult to separate from the oil-rich kernels; the seeds also contain a toxic substance called gossypol that processors must deactivate. Without the right equipment, cottonseed processing can cause a mess and can even pose a safety hazard.