Cottonseed Oil Extraction Machine in indonesia

- Type: cottonseed oil extraction machine

- Usage/Application: cottonseed

- Production capacity: 30-200 tpd

- Voltage: 220V/380V/440V

- Weight: 2000--5000 tons

- Dimension (L*W*H): 1000m*800m*30m

- Power (W): 40 kw/h

- Country: indonesia

Complete 200 TPD Cotton Seed Oil Processing Plant installed in indonesia. Recently, our client in indonesia ordered a 200 TPD high-capacity oil processing line to process cotton seeds. The main equipment involved in the cotton oil Processing plant are Seed Cleaner, cooker, Screw press, Neutralizer, bucket elevator and screw conveyor.

Automatic 200 TPD Cottonseed Oil Processing Plant installed

- Type: cottonseed oil processing machine

- Production capacity: 10T-5000TPD

- Voltage: 220V/380V

- Weight: 2T-20T

- Dimension (L*W*H): 2500mm*2000mm*3000mm

- Power (W): 25kw-44kw

Recently, our client in indonesia ordered a 200 TPD high-capacity oil processing line to process cotton seeds. The main equipment involved in the cotton oil Processing plant are Seed Cleaner, cooker, Screw press, Neutralizer, bucket elevator and screw conveyor.

The working principle of the cotton seed oil expeller machine is to forcefully push the cottonseeds through the chamber by the action of the rotating screws. As the cottonseeds move towards the discharge end, the screw pitch reduces thereby causing compression.

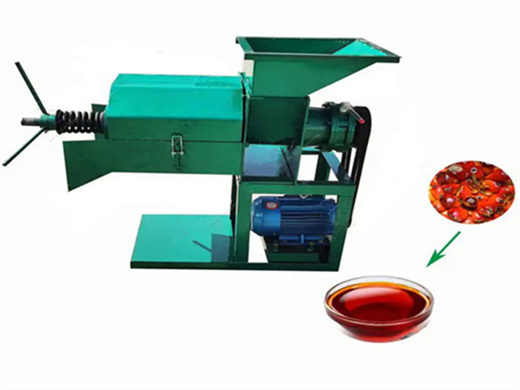

fully screw press oil expeller design in indonesia

- Usage: cottonseed oil

- Production capacity: 300-400kg/h

- Voltage: 220V/380V

- Main components: motor, pump, bearing, others

- Weight: 1500 KG

- Dimension (L*W*H): 2300x1300x2200mm

What is a screw press oil expeller? The document describes the design and fabrication of a small-scale screw press oil expeller. Key features include a feeding hopper, cylindrical casing housing an interrupted screw drum, oil and cake outlets. In operation, the screw drum conveys, crushes and presses oilseeds, extracting oil through perforations. Can a mechanical […]

Cottonseed oil is a cooking oil extracted from the seeds of cotton plant of various species, mainly Gossypium hirsutum and Gossypium herbaceum. Cotton grown for oil extraction is one of the big four genetically modified crops grown around the world, next to soy, corn, and rapeseed (canola), mostly Monsanto products. Once processed, cottonseed oil has a mild taste and appears generally clear with a light golden color, the amount of color depending on the amount of refining. Cottonseed oil has a relatively high smoke point as a frying medium. Like other long-chain fatty acid oils, cottonseed oil has a smoke point of about 450 ℉ (232 ℃).

Oil Press Machine, Oil Extraction Machine in indonesia - Goyum

- Type: cooking oil extraction machine

- Production capacity: 10 -5000TPD

- Voltage: 380v 440v

- Weight: As cooking oil extruders by capacity

- Dimension (L*W*H): As cooking oil extruders by output

- Power (W): As daily production of cooking oil extruders

Note: The above mentioned Capacity Range includes single pressing as well as pre-pressing. Further capacity differs as per the oil content and density of oilseeds and nuts too. Are you looking for the most suitable and cost effective Oil Press Machine or Oil Mill Plant to start your own Oil Manufacturing Business, then you are in the right place.

Automatic 200 TPD Cottonseed Oil Processing Plant installed in indonesia. Complete 200 TPD Cotton Seed Oil Processing Plant installed in indonesia. Recently, our client in indonesia ordered a 200 TPD high-capacity oil processing line to process cotton seeds. The main equipment involved in the cotton oil Processing plant are Seed Cleaner, cooker, Screw press

cotton seed oil production machine line in indonesia

- Raw Material: cottonseed oil

- Production capacity: 100 kg/h

- Dimension (L*W*H): 1700 *1100*1600mm

- Voltage: 220 V/380 V

- Weight: 1200 KG

- Main components: Others

We offer cotton seed oil processing plant for either small scale or big scale according to differnet needs of our customer. The small scale cotton seed oil processing plant involves several processes like entry into the shaker room, where the cotton seeds are cleaned, the cleaned cotton is send through the grin sand where linter’s are removed from the cotton seed. The next step is passing them through hullers, where the tough seed coats are removed.

Learn about these points before you start your own cotton seed oil mill plant: Conduct thorough research on the what you require for cottonseed oil business in terms of market size, capital and trends. Know your competitors. Make a business plan and write down your planned location, finances and target market. Learn about the rules and regulations. Employ candidates those who are experienced in the cooking oil manufacturing process.