Cottonseed Oil Production Line | Cotton Seed Oil Extraction

- Type: cottonseed oil refining equipment

- Usage/Application: cottonseed

- Production capacity: 450 kg/h

- Voltage: 380V50hz

- Main components: motor, pressure vessel

- Weight: 850 kg

- Dimension (L*W*H): 800*700* 1400 mm

- Country: johannesburg

Cottonseed oil deodorization. The purpose of oil deodorization is to remove odor-causing substances and other easily volatile substances in the oil, improve the odor and color of the oil, and improve the stability of the oil. Cottonseed oil refinery machines are divided into three types: batch type, semi-continuous, and full-continuous.

Leader in Grain and Oil Machinery Manufacturer - Hongde Group

- Type: cottonseed oil refinery machine

- After-sales service: spare parts, field service

- Voltage: 380V

- Custom: Custom

- Press Series: Second

- Press Materials: Sunflower, Soy, Coconut, Peanut, Mustard

Hongde Group is a quality partner of China's top 500 companies. 37 years of innovation and development have forged Hongde Group's leadership in the manufacturing industry, and it is committed to becoming the world's most trusted grain and oil equipment and solution provider.

The main processes of oil refining workshop: degumming, dehydration, bleaching, deacidification, deodorization, dewaxing, degrease. Pressed crude oil E-mail:info@Hongdeoilplant.com TEL:0086 372 5319308

Hongde Provides Turnkey Oil Mill Plant, Oil Pressing Machine

- Usage: cottonseed oil

- Plate Type: Flatbed Printer

- Color and Page: Multicolor

- Weight: 930 KG

- Dimensions (L*W*H): 210*108*150cm

- Voltage: 220 V/380 V/ 110V

Cotton Seed Oil Refinery Plant. Oil Refining is the progress of removing impurities such as phospholipids, FFA, pigment, and off-flavor in cruel oil before edible application. An oil refining machine is used for producing the first or second-grade edible oil. We are able to supply the professional oil refining plant and related oil refining

Henan Hongde Cereals And Oils Machinery Co.,Ltd. is a large-scale oil machinery manufacturing enterprise. Professional oil equipment manufacturer Hongde Machinery specializes in the production of large-scale oilseed pretreatment and pressing, oil extraction, oil refining equipments.

Supply Turnkey Cottonseed Oil Mill Project-Hongde Cereals

- Type: cooking oil refining machine

- Production capacity: 30 kg/h

- Dimension (L*W*H): 3340x2100x2160<br /Weight: 6400 KG

- Voltage: 220 V

- Main components: Pump, PLC

- Oil type: Cooking oil, animal fat oil

The Cottonseed Oil Refining Process: Crude cottonseed oil needs to be refined and impurized by cottonseed oil refining machine to remove various impurities and trace elements such as colloid-soluble impurities, free fatty acids, pigments, moisture, wax, and cotton phenol in the crude oil to obtain the finished first-grade leached cottonseed oil.

The main business scope of Henan Hongde Cereals and Oils Machinery Co., Ltd. complete oil pressing production line, complete solvent extraction production line, complete oil refining fractionation production line, high/low-temperature soy protein production line; grains processing project, corn deep processing project, wheat flour processing project, feed machinery, biodiesel equipment and so on.

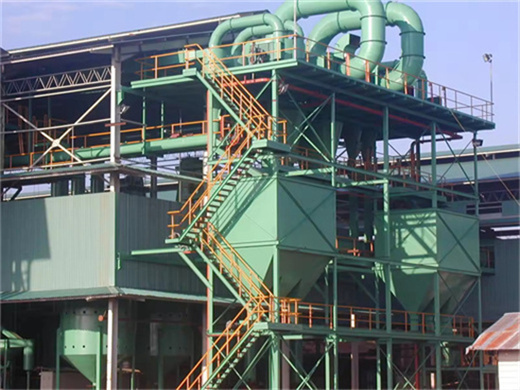

Crude Oil Refinery Section - Hongde Oil Machinery

- Raw Material: cottonseed oil

- Production capacity: 5TPD-100TPD

- Dimension (L*W*H): 700*800*780mm

- Voltage: 220V/380V

- Weight: 240 KG

- Main components: Motor

Soybean oil, sunflower seed oil, Rapeseed Oil, cottonseed oil, peanut oil, palm oil, copra oil, rice bran oil, animal oil all refined oil. Production capacity of refining workshop:10-1000T/day We have more than 200 running oil processing plant around the world and have extensive experience in oil mill construction.

Hongde machinery has developed projects including large scale oilseed pretreatment and pressing, oil extraction, oil refining and oil fractionation production line project,conveyor equipment project,corn/maize flour, grits, germ milling machines and corn processing lines,biodiesel technology,cottonseed, rice bran and soybean protein technology