Sunflower Oil Refining Machinery - Find Oil Refinery

- Type: sunflower oil machine

- Usage/Application: sunflower

- Production capacity: 2-2000 T/D

- Voltage: 400/380/220V

- Weight: 18600KG

- Dimension (L*W*H): 19*12*15M

- Power (W): electricity

- Country: lagos

The oil bleaching is also named decolorization in oil refinery processes. This process’s main purpose is to remove the product of oxidation, pigments, phospholipids, soap materials from the oil. In the oil refinery plant, this process can improve the oil color as well as supplies high quality oil for the deodorization process. Deodorization

Sunflower Oil Refinery Plant

- Type: sunflower oil processing machine

- Production capacity: 100% sunflower seed pressing machine

- Voltage: 220V/380V/440V

- Weight: According to processing capacity

- Dimension (L*W*H): 1200*400*900mm3

- Power (W): 10-50kw

Our Batch Type Sunflower Oil Refinery Plant will give High-Quality Refined Sunflower Oil as Output. Functions of Sunflower Oil Refining Equipments – Neutralization Reactor: For acid refining, alkali refining and water washing. Decolorization Reactor: To Bleach the Oil and remove pigment from oil.

Bleaching. This is one the important stage in total refining process. Where the oil is heated to 100°C to 105°C and mixed with Bleaching earth chemical ( Acid Activated Clay) and also activated carbon in a vessel under vacuum at 70 mmHg where the stirring continues for specific designated time and then filtered the oil to remove the clay and carbon.

Oil Press & Refinery Solution - SINODER

- Usage: sunflower oil

- Production capacity: 50-500kg/h

- Voltage: 220V/110v

- Main components: motor, pressure vessel, pump

- Weight: 11 kg

- Dimension (L*W*H): 450*160*300m

Some kinds of oil like sunflower, maize germ or corn oil have waxes inside, if these impurities are not removed, the oil will freeze easily under low temperature, thus effecting oil quality and appearance. so this process is necessary in extremely cold areas. Some Edible Oil Refining Equipment Instruction 1. Decoloring tank: bleach pigments

Home > Products > Oil refining process Sunflower oil refining machine technology. Contact Us. Phone: 008613526627860 whatsapp: +8613526627860 Tel: +8613526627860

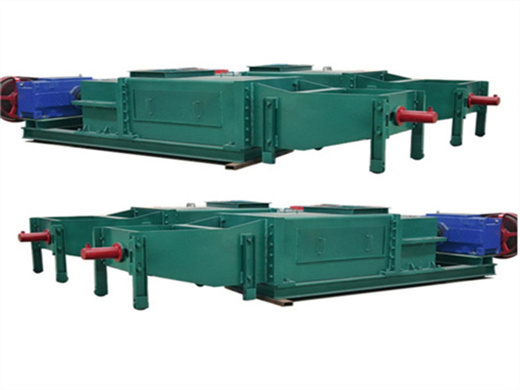

HIBLEACH, Bleacher- Edible Oil Bleaching Plant Manufacturers

- Type: cooking oil extraction machine

- Production capacity: according to essential oil pressing machine specifications

- Power (W): according to the specifications of the essential oil press machine

- Voltage: 220V/380V

- Dimension (L*W*H): according to the specifications of the oil press machine essential

- Weight: according to the specifications of essential oil press machine

HIBLEACH ® Bleacher is equipped with mechanical agitation and steam sparging for better contact between oil and bleaching earth. It operates under vacuum of 710 mm Hg and hasretention time of 40 – 60 minutes for efficient contact and adsorption of color pigments and other impurities on to the Bleaching earth.

Sunflower oil deodorization machine (2584 products available) Previous slide Next slide. Small refining and deodorizing sunflower oil equipment machine for hemp oil.

crude cooking oil refinery machine – sunflower

- Raw Material: sunflower

- Production capacity: 100% cooking oil press machine

- Power (W): 5.5 ~ 18.5 KW

- Voltage: 220V/380V/440V

- Dimension (L*W) *H): 1950*1300*1900, according to capacity

- Weight: 950KG

Sunflower oil refinery plant includes a series process, such as degumming, neutralization, bleaching, deodorization and dewaxing Oil. Sunflower oil refining machine from crude oil to first grade. Sunflower oil refining machine from crude oil to first grade An industrial sunflower oil refining machine ( cooking oil refinery equipment) is

Oil bleaching is carried out before deodorization in an edible oil refinery. The process removes color, as well as residual phosphatides, metals and soaps. To do this, clay is added to the oil then heated, upon which it absorbs pigmentation. Lastly, the oil-clay mixture is filtered and the spent cake is dried to remove the oil.