Oil Packing Machine | Automatic Oil Pouch Fill Seal Machine

- Type: peanut oil machine

- Usage/Application: peanut, groundnut

- Production capacity: 1 ton/day

- Voltage: 220 V/380 V/440 V

- Main components: Gearbox

- Warranty: One year warranty against manufacturer defect.

- Dimension (L*W*H): 4.26 *1.55 * 3.52 ft<br /Weight: 0 KG

- Country: rwanda

There are mainly three kinds of oil packaging machines, automatic liquid oil bag packaging machine, small semi-auto oil filling machine, and multi-head oil filling and packing machine. The first type is one kind of vertical pouch packaging machine. The second one is a small filler, occupying a small space.

Automatic Peanut Butter Liquid Vertical Form Fill And Seal

- Type: peanut oil processing machine

- Production capacity: 1-5000T/D

- Voltage: 220V, 380V

- Type of supplier: Cooking oil extraction machinery manufacturer

- Certification: ISO9001

- Power (W): according to its capacity

Automatic Peanut Butter Liquid Vertical Form Fill And Seal Machine(LD-320L), it is suitable for filling liquids and pastes of any fluidity in various industries. Examples: coconut milk, soysauce, sauce, Paste, Ketchup, syrup, peanut butter, juice, honey, jam, oil, etc. Kindly Reminder:

Spout pouch filling machine is a specialized tool designed to efficiently package oil products. This machine utilizes advanced technology to create visually appealing and secure pouches that are perfect for retail packaging. Landpack spout pouch filling machine is capable of producing a wide range of pouch sizes and shapes.

Automatic Oil Pouch Packing Machine - Makwell

- Usage: peanut oil

- Production capacity: 1TPD-1000TPD

- Voltage: 380V

- Weight: changed with capacity

- Dimension (L*W*H): various with capacity

- Power (W): according to capacity

A fully automatic oil packaging machine can make bags, weigh, seal, and cut efficiently. This machine is also affordable and has a small size or footprint. Automatic Oil Pouch Packaging Machine Price. The price of an automatic oil pouch packaging machine will depend on the type of machine, and its size.

At AD Packaging, we specialize in designing, manufacturing, and exporting state-of-the-art oil pouch packing machines that are engineered to meet the diverse needs of our clients worldwide. Our machines are crafted with precision and efficiency to ensure optimal performance and reliability in various production environments.

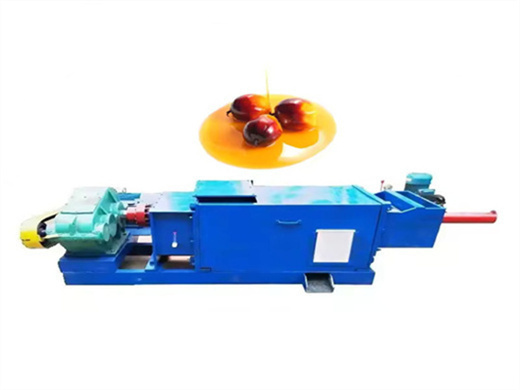

Liquid Full Automatic Peanut Oil Packaging Machine

- Type: cooking oil extraction machine

- Main components: Motor

- Power: 3 kW

- Voltage: 220 V/380 V

- Weight: 150 kg

- Dimension (length x width x height): 1000*700*950 mm

Oil Packing Machine | Automatic Oil Pouch Fill Seal Machine. Peanut Oil Filling And Packaging Machine. Accutek Packaging Equipment | Automatic Packaging Machines. Best Oil Filling Machine For Sale - TopFillers. Edible oil filling machine, machines for the packaging of. Peanut Oil Filling And Packaging Combi-block - Combiblock. Liquid Filling Machine, Automatic Liquid Pouch Packaging

peanut-packing-machine . Application: Vertical Full Automatic Packaging Machine is suitable for packing the high accuracy and easy fragile material such as: puffy food, crispy rice, jelly, candy, pistachio, apple slices, dumpling, chocolate, pet food, small hardwares, medicine, etc. Kindly Reminder:

Machines for Oil Packaging, Techniques, Machinery,

- Raw Material: peanut

- Production capacity: 100%

- Power (W): 15KW

- Voltage: 380V/50HZ

- Dimension (L*W*H): 1700*1100*1600mm

- Weight: 1200kg

This article provides an overview of various methods and machinery for packaging different types of oils. It covers the nuances of packaging edible oils such as olive and peanut oils, as well as non-edible oils like petroleum. The importance of selecting the right packaging machinery is discussed, ranging from semi-automatic filling machines to fully automatic packaging lines, ensuring an

Air Fill Peanut Packaging Machine PLC Control. Peanut Packaging Machine Features: Siemens PLC control system, the output signal is more stable and accurate, bag making, metering, filling, printing and cutting complete by one machine. Independent pneumatic and power control circuit box, low noise and more stable. Servo motor pulls the film with