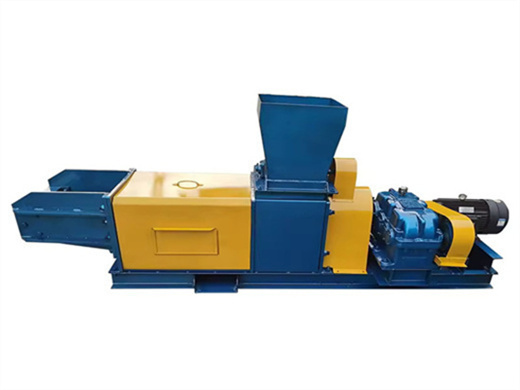

Palm Kernel Oil Expeller for Cold Pressing of Palm Kernel Oil

- Type: palm kernel oil press machine

- Usage/Application: palm fruit, palm kernel

- Production capacity: 93%

- Voltage: 380V/Others

- Main components: motor, pump, gear, bearing, Motor, gearbox

- Weight: 160kgs

- Dimension (L*W*H): 900X550X700mm

- Country: zimbabwe

The palm kernel oil expeller machine is also added with the seed frying and automatic heating function which changes the traditional heating method of cake grinding press, so as to shorten the preparatory work time, reduce the energy consumption & the abrasion of the machine and prolong the service time of expeller.

1tph palm oil refining machine – easy sourcing Chad

- Type: palm oil processing machine

- Production capacity: 50-600 kg/h

- Voltage: 220/380 v

- Main components: motor, pump, gearbox

- Weight: 280 KG

- Dimension (L*W*H): 140*86*126 mm

Palm oil refining machine - Palm oil processing machine. Palm kernel oil processing machine (1-1000tpd) Because of palm nut shell is hard, if pressing directly without kernel and shell separation, machine will wear very fast. So we need to palm kernel cracker and separater machine to crack and separate palm nut more effective.

Our palm kernel oil press is composed of feeder, gearbox, pressing cage, screw shaft ,and machine stand etc. It has better results to press palm kernels. It utilizes the screw shaft that is set-up with different styles of screws and rotates when machine is running to push the material into chamber.

Palm kernel oil extraction machine

- Usage: palm oil

- Production capacity: 10-500 tons/day

- Voltage: 220 V 380 V

- Pressing method: Press screw squeezed

- Oil item: safflower oil pressing machines

- Dimension (length x width x height): 1.2 x 0 .78 x 1.1 m Weight: 300 kg Main components: motor, Pressure vessel, PLC

Palm kernel oil extraction machines are specialized equipment designed to efficiently extract oil from palm kernel seeds. With a growing demand for palm kernel oil

What vegetable seed can your oil press machine process? Our oil expeller machine can process a wide range of plant seeds such as peanut, soybean, sunflower seeds, sesame seed, cottonseed, rapeseeds, corn germ, coconut, palm kernel, jatropha seed, hemp seed etc. How does your oil press work? The seed is placed into the feeder either by labor

Palm Kernel Oil Manufacturing Process With Flowchart - Goyum

- Type: cooking oil extraction machine

- Production capacity: 140-280 kg/h

- Dimension (L*W*H): 1800* 1300*1680 mm

- Voltage: 380 V

- Weight: 1100 KG

- Main components: as the picture shows

The cleaned Kernels are fed to a palm kernel oil expeller machine, which consists of a main shaft and worms, which rotates within a stationary perforated cylinder called a cage or barrel. As the main shaft turns, there is a decrease in volume resulting in pressure in the cage.

After bunch reception, bunch sterilizing, threshing and digesting, the palm fruits are pressed into a screw palm oil press. Mixture of oil and cake will be extracted by use of palm oil press machine. Besides, nuts and fibre or press cake will also be discharged as palm oil pressing residues. Palm Oil Pressing Machine (Oil Extraction)

Palm Oil Equipment,Palm Kernel Screw Press,Oil Expeller - MBL

- Raw Material: palm

- Production capacity: 100TPD

- Dimension (L*W*H): according to capacity

- Voltage: 380V

- Weight: 60000 KG

- Main components warranty: 5 years

Palm Kernel Oil Expellers / Palm Kernel Screw Press are screw type machines that presses oil seeds in order to extract the oil in the seeds. These seeds are fed from one side of the press, which then enters into the pressing chamber. The palm-kernel machines uses pressure and friction from the screw drives to move as well as to compress the oil

Before extracting oil, the palm fruits need to be crushed in digester machines. To augment oil yield, the fruit pulp is also warmed in this process. The mesocarp and nuts can be squeezed together in palm oil making/pressing machine. But if you plan to make Grade A Palm Oil, the palm nut/kernel should be removed before oil pressing section.