peanut oil press machine for sale/large peanut oil processing

- Type: peanut oil processing plant

- Usage/Application: peanut, groundnut

- Production capacity: 20 tons/day

- Voltage: 380V/440V

- Warranty: One year warranty against manufacturing defects.

- Weight: KG

- Dimension (L*W*H): Depends

- Country: uganda

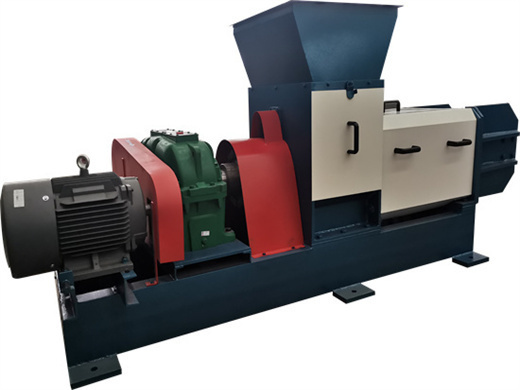

The peanut oil press adopts the row method to greatly reduce the gap of the oil line, increase the pressure of the press chamber, and increase the oil yield. The commercial screw peanut oil expeller machine uses electronic temperature control technology to ensure the best temperature for the oil output rate of the press chamber.

Peanut Oil Production Line,Peanut Oil Pressing Plant - Oil mill

- Type: peanut oil processing machine

- Voltage: 220V/380V/440V

- Power (W): According to capacity

- Certification: ISO9001

- Weight: 1050 KG

- Dimension (L *W*H): 1610x615x1260mm

Medium-scale peanut oil plant (10-50 TPD): More advanced pressing equipment, potentially combined with solvent extraction and semi-automated refining systems. Large-scale peanut oil plant (50+ TPD): Full automation, large capacity pressers, complete solvent extraction plants, and continuous refining units.

The oil content of peanut is approximately 42% to 52% oil. Peanut oil is mainly used for cooking purpose as it contains lots of protein and 80% unsaturated fatty acids like oleic acids and linoleic acids. Peanut oil is in light yellow transparent color and has a fragrant smell, and their taste is very delicious. Groundnut / Peanut Oil Making

Peanut Oil Production Plant Investment Costs Analysis

- Usage: peanut oil

- Production capacity: 100% oil press machine

- Voltage: 220V/380V/440V

- Weight: 950KG

- Dimension (L*W* H): 1950*1300*1900, according to capacity

- Power (W): 5.5 ~ 18.5 KW

The general capacity we can provide for peanut oil processing plant ranges from 5 to 400 tons per day. Taking the smallest peanut oil production line (5TPD) as example, the totally investment for a complete automatic peanut oil production line is $ 8,500 around (Not include the oil refining equipment). Please note all the equipment included in

For small scale peanut oil production plant, we can offer 50kg/h to 500kg/h peanut oil press machine. One kind is single screw oil presser, and the another is single screw oil presser with filter. Using the single screw peanut oil presser, you process about 10 tons of peanut kernels per day, and you will get around 4-5 tons crude peanut oil.

Complete Facility of Peanut Oil Processing Mill | Edible Oil

- Type: cooking oil extraction machine

- Production capacity: 96%

- Dimension (L*W*H): 55*30*35cm

- Voltage: 220v/110v

- Weight: 12 KG

- Main components: motor, pressure vessel, pump, others, gears, bearings, motor, gearbox

Small oil mill adopts screw oil expeller to extract oil, so it has all the merits of screw peanut oil press. So, it is very easy to operate and maintain. Reliable Peanut Oil Mill Supplier. 5TPD Peanut Oil Processing Plant Exported to Sudan. Above is a customized small scale peanut oil mill exported to Suda. This is the picture we taken in our

The screw peanut oil or Groundnut oil machine can ensure the original cell structure of the peanut is destroyed under mechanical force to obtain a pressed crude oil. During processing, press the conditioned oil seeds or oil-bearing material using a lever press, hydraulic press or a mechanical expeller to remove the oil.

Choose Right Groundnut/Peanut Oil Extraction Machines

- Raw Material: peanut

- Production capacity: 20~2000T/D

- Power (W) : up to specification

- Voltage: 380v/50Hz

- Dimension (L*W) *H): 1360*950*1170mm

- Weight: as per specification

Above is the main peanut oil extraction methods that are widely used in commercial vegetable oil processing plant to improve the oil production efficiency and oil quality. Before starting the peanut oil extraction process, the peanut/groundnut should be pretreated to ensure high oil output.

(1) Peanut oil is extracted by pure physical pressing method, and the whole peanut oil processing process completely avoids the contact between raw materials and chemical solvents; (2) During peanut oil processing, unfavorable refining processes such as solvent leaching, alkali refining, deodorization, etc., which affect the quality of refined