Mechanical Methods of Oil Extraction from Peanuts

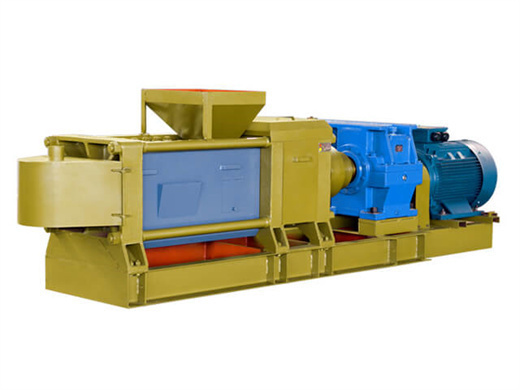

- Type: peanut oil extraction machine

- Usage/Application: peanut, groundnut

- Voltage: 220 V/380 V/440 V

- Power (W): depends on capacity

- Certification: ISO9001

- Weight: 850 KG

- Dimension (L*W) *H): 5432* 2636*2345

- Country: kenya

They include organic solvent extraction, such as hexane S. Aqueous enzymatic extraction of peanut oil and protein hydrolysates. Food Bioprod. Process. 2010, 88

Peanut Oil Processing Technology - ScienceDirect

- Type: peanut oil processing machine

- Voltage: 380V/50HZ

- Power (W): 22kw

- Certification: CE ISO

- Weight: 10 tons

- Dimension (L*W*H): 48m*12M*15M(30TPD)

The mixed oil produced from leaching comprises volatile solvent, nonvolatile oil dissolved therein, and 0.4–1.0% solid meal powder. The purpose of the procedures is to separate the solvent from the mixed oil and remove the solid meal powder to obtain relatively pure crude oil.

This review elucidates the methods used for extracting peanut oil, including mechanical and chemical processes that have been combined with biological or physical pre-treatment techniques.

Groundnut Oil Manufacturing Process With Flowchart - Goyum

- Usage: peanut oil

- Voltage: 380 V

- Power (W): 30 KW

- Warranty: 12 months

- Certification: CE

- Dimension (L*W *H): 10500 *1440*1750mm

Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method. According to mechanical pressing technology, you can divide the peanut oil production process into three phases. These are peanuts preparation, pressing and crude oil refining.

extraction of oil from groundnuts. In the present study celluclast 1.5L was used for the pre-treatment. The effect of enzyme concentration (5-10%), temperature (50-60⁰C), pH (5.0-6.0), reaction time (1-7 h) on free oil liberated was studied. Residual oil was collected by subjecting the treated meal to soxhlet extraction for 4 h.

What are the common extraction methods of extracting peanut

- Type: cooking oil extraction machine

- Production capacity: 5TPD-100TPD

- Voltage: 220V/380V

- Main components: motor, pressure vessel, Pump, PLC, Gear, Bearing, Motor, Gearbox

- Weight: KG

- Dimension (L*W*H): According to specifications

The dry meal will be packaged for sale as animal feed. Usually, by using the peanut oil extraction method, the residual oil in the cake will be less than 1%. But different with peanut oil pressing method is that peanut oil obtained by solvent extraction method must be refined before it can be eaten.

Peanut oil is an organic edible vegetable oil, obtained by pressing peanut kernels, which contain about 50% oil. Peanut oil has high energy and very good lipid profile. Its smoke point is very high, so it’s widely used in deep frying. What’s more, peanut oil is one of the healthiest cooking oils as it is low in saturated fats, free from

Various methods for extracting oil from groundnut

- Raw Material: peanut

- Voltage: 380V

- Dimension (L*W*H): Various with capacity

- Power (W): According to capacity

- Weight: Changed with capacity

- Oil yield rate: 12 -18%

Groundnut oil pre-pressing machine can extract most of groundnut oil, the groundnut oil solvent extraction plant can recover almost all the oils and leaves behind only 0.7% to 1% residual oil in the raw material. In the case of mechanical pressing the residual oil left in the oil cake may be anywhere from 6% to 14%.

The remaining oil is then extracted using the solvent extraction method. If using mechanical pressing technology, the oil production process consists of three key stages: preparation of peanuts, pressing, and refining of crude oil. The overall extraction process involves five steps: cleaning, dehulling, cooking, pressing, and filtering.