(PDF) Defatting and Defatted Peanuts: A Critical Review on

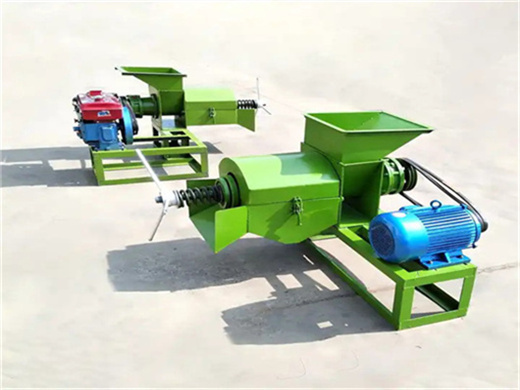

- Type: peanut oil extraction machine

- Usage/Application: peanut, groundnut

- Production capacity: according to capacity

- Voltage: 110V, 220V, 380V , 440 V

- Weight: 1050 KG

- Dimension (L*W*H): 1610x615x1260mm

- Power (W): according to capacity

- Country: johannesburg

This review elucidates the methods used for extracting peanut oil, including mechanical and chemical processes that have been combined with biological or physical pre-treatment techniques.

Groundnut Oil Manufacturing Process With Flowchart - Goyum

- Type: peanut oil processing machine

- Production capacity: 5~15TPD(24 hours), 5~15TPD

- Voltage: according to capacity

- Power: 14KW

- Dimension (L *W*H): 1200*400*900mm3

- Power (W): 2.2 KW

Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method. According to mechanical pressing technology, you can divide the peanut oil production process into three phases. These are peanuts preparation, pressing and crude oil refining.

The peanuts are then crushed into smaller pieces, which helps release the oil. After crushing, the peanut pieces are passed through rollers to form thin flakes. This increases the surface area and makes the oil extraction process more efficient. 5. Oil Extraction. There are two main methods for extracting oil from the peanut flakes: a.

The Extraction of Peanut Oil and Its Diverse Uses - LinkedIn

- Usage: peanut oil

- Voltage: 220V/380V

- Dimension (L*W*H): 2000*1100*1950mm3

- Oil type: Cooking oil

- Main components: motor, pressure vessel, pump, PLC, gear, bearing, Motor, Gearbox

- Weight: 450 KG

The use of peanut cake in animal feed contributes to the sustainability of the peanut oil extraction process by ensuring that all parts of the peanut are utilized. 3.5. Traditional and Cultural Uses

It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology. At the end of the chapter, it discusses the peanut oil production line and the relevant key equipment.

Peanuts Mechanical Methods of Oil Extraction from

- Type: cooking oil extraction machine

- Production capacity: 20-100T/D corn oil press factory

- Power (W): Capacity

- Voltage: match local voltage, Math with local voltage

- Dimension (L*W*H): according to factory capacity corn oil press

- Weight: 1000 kg

M e cha nica l M e tho ds o f Oil Ex tra ctio n f ro m P e a nuts | Ency clo pe dia . pub https: / / e ncy clo pe dia . pub/ e ntry / 48924 1/ 14 Mechanical Methods of Oil Extraction from Peanuts Subjects: Engineering, Industrial Contributor: Freddy Mahfoud , Jean Claude Assaf , Rudolph Elias , Espérance Debs , Nicolas Louka

filtered groundnut oil: filtered groundnut oil is an excellent choice for this process as its purity and clarity ensure optimal oil extraction. The absence of impurities in double-filtered oil prevents gumming up the machinery and contributes to a smoother extraction process. 4. Pressing . Objective: To extract the oil from the cooked peanuts

Groundnut Oil Making Process (Peanut), Business Plan

- Raw Material: peanut

- Production capacity: 1-500t/24h

- Dimension (L*W*H): According to your capacity

- Voltage: customized

- Weight: KG

- Main components: Pressure container

Therefore, it is essential to equip the peanut oil production plant with professional edible oil refinery equipment to get them off and obtain the refined high-quality peanut oil. Groundnut Oil Processing Flowchart. Cost of Groundnut oil extraction machine: Generally, the cost of Groundnut oil extraction machine will be approximately Rs 1.8

Peanuts are the main oil crops and contain high nutrition, but the quality, color, taste and even the oil yield of the peanut oil extracted by different peanut oil extraction machine are different. These are inseparable from the causes of the press, but they are also related to the different processing methods.