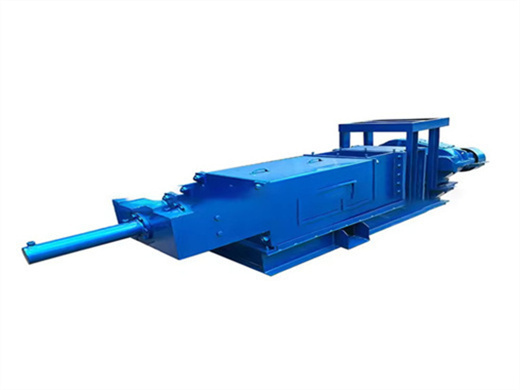

Sunflower Oil Extraction Process, Methods – A Full Guide

- Type: sunflower oil refining machine

- Usage/Application: sunflower

- Production capacity: 5-500 TPD

- Voltage: 440 V

- After-sales service provided: Engineers available to service machinery abroad.

- Certification: ISO,CE

- Weight: 500 TONS

- Country: lagos

Sunflower seeds from the oil-type contain about 20% to 30% hulls that are sometimes removed before oil extraction to ensure the quality of both oil and sunflower meal. De-hulling is completed when the seed has a moisture content of 5% after cleaning.

Sunflower Seed Preparation and Oil Extraction - ScienceDirect

- Type: sunflower oil refinery machine

- Production capacity: 100-180 kg/h

- Voltage: 220v / 380v / 415v

- Warranty: 2 years

- Weight: 155 KG

- Dimension (L*W*H): 1700mm x 1300mm x 1750mm

Because sunflower oil has a substantially higher economic value than sunflower meal, process economics improve significantly as the oil recovery yield increases. Therefore, prepress solvent extraction, with the highest oil recovery yield, is the process method utilized today for the majority of the sunflower seed that is crushed globally.

Factors Affecting Sunflower Oil Extraction Yield. The yield of sunflower oil extraction can be affected by various factors, including seed quality, processing conditions, and extraction methods. The quality of the seeds used for extraction is a crucial factor that can significantly impact the yield of the oil.

Extracting and refining steps of sunflower oil. | Download

- Usage: sunflower oil

- Production capacity: 30--80hg/h

- Voltage: 220V/380V

- Key selling points: Automatic

- Warranty: 1 year

- Dimension (L*W*H): 1220*820*1220mm<br /Weight: 268 KG

Figure 1 represents schematically the main steps of sunflower oil extraction and refining. There are five main stages where there is a potential leak of minor components: Degumming, neutralization

One of the factors of sunflower oil is its typical properties of wax. Sunflower oil contains wax from 1000 ppm to 1500 ppm based on the variety of seeds. The wax give haziness to the oil after refining. Hence it becomes necessary to remove the wax to avoid haziness of the oil and also stickiness of the Oil.

Sunflower Seed Preparation and Oil Extraction - ResearchGate

- Type: cooking oil refining machine

- Production capacity: 30kg-30t/day

- Power (W): Depends on the machine you choose

- Voltage: 380V or designed according to your needs

- Dimension (L*W*H): Depends on the machine you choose

- Weight: Depends on the machine you choose

Rukmana (2004) states that the content of sunflower oil's content ranges from 23 to 45%. 11.7% oleic acid and 44-72% linoleic acid are both present in sunflower oil.

sunflower seed oil indicates that it is combustible oil rather than flammable oil. Specific gravity (S.G) of the sunflower oil obtained is 0.9157 ± 0.0002. This value was the ratio of the density of the sunflower oil to the density of equal volume of water at the same temperature. The value obtained indicates that the

PHYSICAL REFINING OF SUNFLOWER OIL

- Raw Material: sunflower

- Automatic Grade: Semi-automatic

- Voltage: 220V/380V

- Production capacity: 1TPD-1000TPD

- Power (W): 7.5kw

- Dimension (L*W*H): 1.5*2.6*3.6M

Sunflower oil has a high nutritional value, having 62-70% linoleic acid content (essential fatty acid) but on the other hand this high polyunsaturated fatty acid content makes this oil sensitive to oxidation. Crude sunflower oil, which has reached a certain level of oxidation is difficult to refine. There are two main difficulties: 1.

This process concentrates the polyunsaturated fatty acids in fish oil. Winterization of sunflower oil conducted at 6 • C for 10 h (Suliman et al., 2013) and 15 • C for 4 h (Pal et al., 2015