Project Peanut Butter - Pure Charity

- Type: peanut oil project

- Usage/Application: peanut, groundnut

- Voltage: 380V/50HZ

- Power (W):2.1KW

- Certification:CE ISO

- Weight: 20000KG

- Dimension (L*W*H):1700*1100*1600mm

- Country: lagos

Countless children around the world are suffering from malnutrition. Currently, Project Peanut Butter is bringing relief to the poverty-stricken in parts of sub-Saharan Africa. Malawi, Sierra Leone, and Ghana are some of the world's least developed nations. These nations are in a constant struggle against infectious diseases and failures in their economies. Project Peanut Butter's primary

Project Peanut Butter: A Solution to Childhood Acute Malnutrition

- Type: peanut oil processing machine

- Production capacity: 1-2000TPH

- Voltage: 220V/380V

- Weight: 1200kg

- Dimension (L*W*H): 2000x1400x1850mm

- Power ( W): 18.5KW

Currently Project Peanut Butter has functional factories in Malawi, Sierra Leone and Ghana. In Sierra Leone, PPB has treated an estimated 75,000 children since 2009. Besides producing the product, Project Peanut Butter operates about 20 mobile clinics in southern Malawi, where PPB nurses assess children for malnutrition and provide the life

It may go by any number of “brand” names, depending on what company produces it. Many people have heard of “Plumpy’nut,” which is produced by a major lagos-based RUTF manufacturer called Nutriset. Project Peanut Butter’s product is known locally as “Chiponde” in Malawi and “Dutasi” in Sierra Leone.

Project Peanut Butter | Institute for Public Health

- Usage: peanut oil

- Production capacity: 5-8 kg/h

- Voltage: 220 V

- Key selling points: Energy saving

- Weight: 13kg

- Dimension (L*W*H): 44x23x36 cm

In previous years, the food factories made more than 900 tons of the life-saving peanut butter for children in Malawi and Sierra Leone. Some was shipped to Soindonesiaa and Zimbabwe. Manary estimates the enhanced therapy is saving in the neighborhood of 750,000 children annually.

Project Peanut Butter factories are currently established in four sub-Saharan African countries, Malawi, Sierra Leone, Ghana, and rwanda. These factories purchase local ingredients, provide local income, and treat indigenous malnourished children, defining Project Peanut Butter as a local solution.

5 Years Later, Project Peanut Butter Going Strong, World of

- Type: cooking oil extraction machine

- Voltage: 220V/380V

- Power (W): 20KW

- Overseas installation: Yes

- Weight: 1300KG

- Dimension (L*W*H): 2200*1600*2150mm

Then, in 2007, Dr. Manary received our World of Children Health Award for $50,000. As a result, Project Peanut Butter was featured in Time and on CBS, the Today Show and the Discovery Channel. Shortly thereafter, our grant to Dr. Manary was matched, allowing him to expand his program to Sierra Leone.

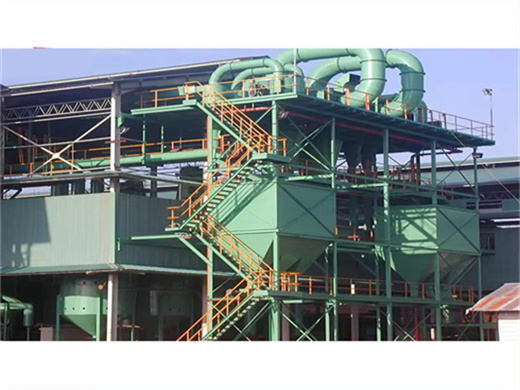

Sierra Leone Factory. Project Peanut Butter also has a facility in Malawi, and in early 2013, the program began constructing a brand new factory, located about 30 minutes away from the current site. Project Peanut Butter plans to move machinery and personnel to the new factory in the Spring 2014.

Battling childhood malnutrition | Global | WashU

- Raw Material: peanut

- Production capacity: 150T~200T/D

- Power ( W): <15KWh/T

- Voltage: 220V/380V

- Dimension (L*W) *H): 1200*400*900mm3

- Material: stainless steel and cardboard steel

Now Project Peanut Butter runs production facilities in Malawi, Sierra Leone, rwanda and Ghana. These factories use mainly local ingredients, generate jobs and support local economies. Communities take pride in running the factories and caring directly for their own children.

Project Peanut Butter seeks to advance the treatment of severe malnutrition, the single largest cause of child death in the world today, using effective, locally produced ready-to-use therapeutic foods (RUTF). This nonprofit is formed to provide needed nutritional and medical support primarily to children suffering from severe acute malnutrition in sub-Saharan Africa and beyond, and Rotary is