Cottonseed oil mill plant manufacturers

- Type: cottonseed seed oil extraction machine

- Usage/Application: cottonseed

- Voltage: 220 V

- Weight: 590 KG

- Keyword: Seed Oil Pressing Machine

- Oil type: cooking oil

- Main components: pump, PLC

- Country: zambia

Cottonseed Oil Extraction Process. Our cottonseed oil extraction plant uses a well-structured process to extract premium oil from cotton seeds. With precise cleaning, dehulling, and solvent extraction, we ensure maximum yield and purity for various industrial and edible applications.

Cottonseed Oil Processing Machines Set up Complete Oil Mill Plant

- Type: cottonseed oil processing machine

- Production capacity: 5.50 kg/h

- Voltage: 110-220 V

- Main components: Motor, PLC

- Weight: 11 KG

- Dimension (L*W*H): 53x27x35cm

Small Cotton Seed Oil Processing Plant. The pre-treatment equipment used in cotton seed oil pressing plant for cottonseed includes cleaning equipment (magnetic separator, cleaning screen and destoner), sheller, shell separating screen, embryo flaking machine, steam frying pan or cooking machine, and a series of other equipment.

Application of Cottonseed Oil. The cottonseed oil is cholesterol free and extracted from the seeds of various cotton plants. More than 95% of the cottonseed oil is primarily used as cooking oil. Cottonseed oil is light golden color with light mild taste. It is used primarily in the form of mayonnaise or in addition to salads.

Cottonseed Oil Mill Plant

- Usage: cottonseed oil

- Residual oil in flour: less than 1%

- Solvent consumption : less than 2 kg/t

- Crude oil moisture and volatile matter: ≤ 0.30%

- Moisture of finished food: ≤ 13% (adjustable)

- Energy consumption: no more than 15 KWh /T

Cottonseed oil is extracted from the seeds of cotton plants. Refined cotton seed oil is edible. India, China, Pakistan, USA and Brazil are among the top producers of cotton seed oil in the world. Let us now know about the various aspects of cottonseed oil plant - it's manufacturing process, world market status and other features.

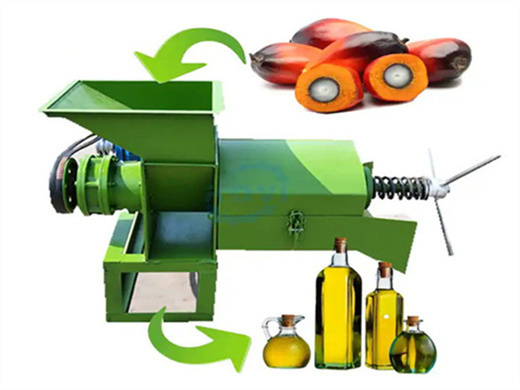

A Cotton Seed Oil Expeller is a machine designed to extract oil from cotton seeds using mechanical pressure. Operating with mechanical efficiency, it ensures a thorough extraction process without the use of heat or chemicals. The resulting cotton seed oil maintains its natural properties, making it suitable for various applications.

Cottonseed Oil Expeller / Extraction Machine Manufacturers

- Type: cooking oil extraction machine

- Production capacity: 98%

- Power ( W): 11 KW

- Voltage: 220 V/380 V/440 V

- Dimension (L*W*H) : 1.5*2.6*3.6M

- Weight: 0.5-10T

The Goyum MK-IV extruder is an advanced cotton seed oil expeller which is developed according the market demands. The GOYUM oil expeller machine capacity is starting from 1 ton per day, and today GOYUM expellers are universally used for the continuous mechanical oil extraction.

The whole oil making machine includes: oil pretreatment machine, oil extraction plant, oil refining line. Pretreatment and prepressing section is a very important section before extraction.It will directly affect extraction effect. Cottonseed oil pre-pressing&extraction craft flow: cottoneseed → clean→seperate → seed ↓ cottonseed hull

Cottonseed Oil Processing Plant | Extraction Flow

- Raw Material: cottonseed oil

- Production capacity: 50-1000TPD

- Power (W): As output of sunflower oil dewaxing machine

- Voltage: 380v 440v

- Dimension (L*W*H): As production of sunflower oil dewaxing machine per day

- Weight: Depends on the production of the sunflower oil dewaxing machine

Cottonseed Oil Decolorization. The main purpose of bleaching is to remove pigments from cottonseed oil to improve the color and appearance of the oil. First, we need to heat the degummed (or deacidified) cottonseed oil to 110-120°C. Second, add 0.5-1.5% of an adsorbent such as activated carbon or clay.

What can we do for oil seeds? Our Process. Cottonseed pretreatment process: delinting → cleaning → shelling → conditioning → flaking→ extruding → cooling; After the cotton kernel is conditioned and flaked, the oil extraction rate and crude oil quality will be greatly improved.