Goyum Screw Press - Oil Processing Machine Manufacturer

- Type: cottonseed oil processing machine

- Usage/Application: cottonseed

- Production capacity: 100% cooking oil expeller

- Voltage: 220V/380V/440V

- Weight: 950KG

- Dimension (L*W*H): 1950*1300*1900, according to capacity

- Power (W): 5.5 ~ 18.5 KW

- Country: zimbabwe

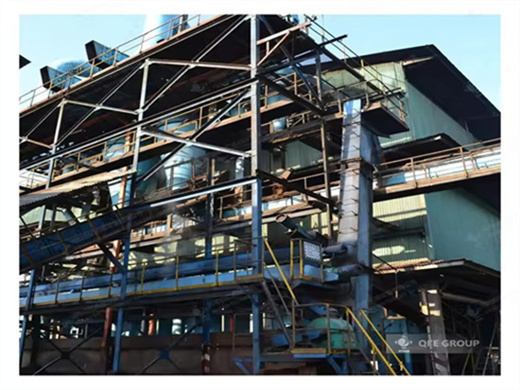

GOYUM SCREW PRESS is a leading Project Engineering Company established in 1971 and now a prominent name in the Oilseed's Oil Extraction Plant, Edible & Non-Edible Oil Processing Plants & Allied Industry.

Cottonseed Oil Mill Plant

- Type: cottonseed oil processing machine

- Voltage: 380V

- Power (W): according to capacity

- Certification: CE and ISO

- Weight: changes with capacity

- Dimension (L*W* H): various with capacity

Cottonseed oil is extracted from the seeds of cotton plants. Refined cotton seed oil is edible. India, China, Pakistan, USA and Brazil are among the top producers of cotton seed oil in the world. Let us now know about the various aspects of cottonseed oil plant - it's manufacturing process, world market status and other features.

Oil expeller machine is the soul equipment of the pressing process, it can be divided into small oil press and high capacity oil press according to its capacity. The top features of cotton seed oil expeller machine are based on the traditional product but include a variety of enhancements, implemented after-in-depth research on cotton seed oil

Steps of Cottonseed Oil Processing Process - Oil Mill Machinery

- Usage: cottonseed oil

- Production capacity: 100%

- Voltage: 220V/380V/440V

- Raw material: FFB, palm kernel

- Weight: 1000 kg

- Power (W): 11 KW Dimension (L*W*H): According to machine capacity

Cracking: Adopting the toothed cracking roller to make the cotton seeds kernel into a right uniform pcs which can keep a moderate block size for squeezing out the oil. Flaking: To make cracked Cotton seeds kernel pcs into uniform smaller flakes with thickness ≤ 0.5mm, less powder, non-oil spilled, pinching softly by hand and the ratio of

Business Scope of Cooking Oil Processing Machine: 1-2000tpd oilseeds pretreatment & pressing processing plant; 30-2000tpd cooking oil solvent extraction plant; 1-1000tpd crude edible oil refinery plant; Other single equipment.

Performance analysis of double screw press - Chuantai

- Type: cooking oil extraction machine

- Production capacity: 200-380 kg/h

- Dimension (length x width x height): 2430x1250x2850 mm

- Voltage: 220 V

- Weight: 1680 kg

- Main components: motor, pressure vessel, pump

The oil flows out through the oil outlet, and the residue is squeezed to the other end of the oil pressing chamber and discharged. 2. Performance advantages of double screw press. High efficiency: Compared with traditional manual oil pressing and single screw press, the double screw press has higher oil extraction efficiency.

Complete set cottonseed oil processing machine are generally divided into three processes, They are: cottonseed oil pretreatment and pre-pressing machine, cottonseed oil solvent extraction plant and cottonseed oil refinery plant. Here we focus on introduction the cottonseed oil processing process, which from cottonseeds to crude cottonseed oil and refined cottonseed oil.

Cottonseed Oil Expeller Manufacturer, Seed Cleaning Machinery

- Raw Material: cottonseed oil

- After-sales service: Technical support

- Voltage: 380V

- Warranty: 12 months

- Appearance: Horizontal

- Press materials: Palm

Established in 2004, Mitsun Engineering is an exporter and manufacturer of engineering machinery such as Oil Expellers, Cottonseed Oil Expeller, Cotton Seed Expeller, Seed Cleaning Machinery. Our company has the capability to supply various types of machines as per the drawings of the clients and their specific requirements.

Double screw press, also known as a twin screw press, is a machine used for extracting juice or liquids from materials with high fiber content. It is designed with two screws rotating in opposite directions. This design makes it ideal for processing various materials such as grapes, gingers, herbal residues, sugarcane, and pulp.