Cottonseed Oil Refinery Plant Oil Making Machine in lusaka

- Type: cottonseed oil processing machine

- Usage/Application: cottonseed

- Warranty: 3 months

- Model: EB-177 ELEMENT inline filter EB177 Compressor part

- Diameter (inches): 3-4.4

- Length:25 inches

- Minimum order quantity: 3 pieces

- Country: lusaka

Complete Equipment and Machinery for Cottonseed Oil Mill Plant. Removing the Hulls. Hulls makeup about 40% to 55% percent of cottonseeds and also has 0.3% to 1% oil. You can get 14% to 25% oil from cottonseed and 30% to 40% oil from the kernels.

Cottonseed Oil Extraction Plant

- Type: cottonseed oil refinery machine

- Production capacity: 10T-100T/D

- Voltage: 220V/380V

- Weight: According to the actual situation

- Dimension (L*W*H): According to the actual situation

- Power (W) : According to the actual situation

Cottonseed kernels contain 0.5%-2.5% of gossypol. After processed by the cottonseed oil refinery plant, the gossypol content in the oil is less than 0.01%. The products of the cottonseed oil processing plant are cottonseed oil, cottonseed meal, cottonseed hull, and soapstock. Features of Cottonseed Oil Processing Plant. 1.

The company has attained prominent leadership in the field of Complete Vegetable Oil Extraction Mill, Solvent Extraction Plant & Edible / Cooking Oil Refinery Plant. Why Us We are serving our valued customers to their complete satisfaction through efficient management and excellent workmanship, which we continue to maintain with our untiring

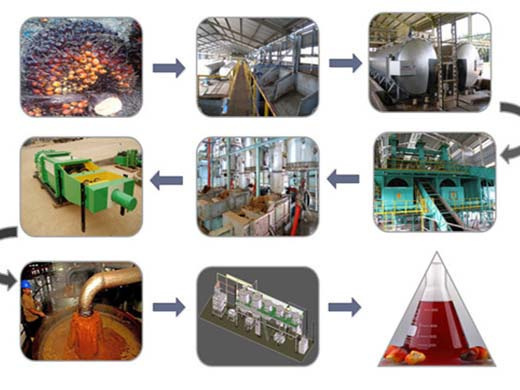

Steps of Cottonseed Oil Processing Process - Oil Mill Machinery

- Usage: cottonseed oil

- Production capacity: over 98%

- Voltage: 220 V/110 V

- Main components warranty: 2 years

- Weight: 23 kg

- Dimension (length x width x height): 560 x 200 x 380 mm .

Within the cottonseed oil processing plant, oils extracted from cottonseed must be refined to remove gossypol, a naturally occurring toxin that protects the cotton plant from insect damage. Cottonseed meal is a good source of protein. It is the byproduct remaining after cotton is ginned and the seeds crushed and the oil extracted.

Fractionation and Refining Crude Cottonseed Oil. 30ton/day Cottonseed Oil Refinery Plant. Refining crude cottonseed oil to produce edible / cooking oil. It involves bleaching, De-acidification, deodorization, and degumming. Fractionation can get solid and liquid oil through solid and liquid separation and cooling crystallization.

Cottonseed Oil Press Machine Cotton Seeds Oil Refinery Plant

- Type: cooking oil refining machine

- Production capacity: 10% residual oil cake

- Dimension (L*W*H): 320*700*850mm

- Voltage: manual

- Weight: 320 kg

- Main components: Motor

3.Cottonseed oil Refinery Plant : A.Flow chart: Degumming →Deacidification →Decoloration → Deodorization →edible oil B. Points for cottonseed oil refining plant ♦ Cottonseed oil refinery can be divided into batch refining (50 t/d) depending on capacity.

Undecorticated Cottonseed obtained after Delinting process can be used as a raw material for Cottonseed Oil Extraction Plant. Cottonseed contains 18 – 20 % oil content. After a single stage pressing, about 6 – 7 % residual oil is left in the cottonseed meal which is an excellent source of Cattle Feed. The working principle of the cotton

Cottonseed Oil Processing Plant | Extraction Flow

- Raw Material: cottonseed oil

- Production capacity: over 98%

- Dimension (L*W*H): 65*30*45 cm

- Voltage: 110 V

- Weight: 20 KG

- Warranty: 1 year

Cottonseed oil contains a large amount of essential fatty acids, among which linoleic acid has the highest content, which can reach 44.0-55.0%. In addition, cottonseed oil also contains 21.6%-24.8% palmitic acid, 1.9-2.4% stearic acid, 18%-30.7% oleic acid, and 0-0.1% arachidic acid. Cottonseed oil can be used for cooking and consumption.

The Cotton Seed Oil is the Oil extracted from cotton seeds which are obtained after removing cotton fiber, lint and hulls. The Kernel in the cotton seed contain oil. The Oil content on delinted seeds will be 15% to 18% and Dehulled Kernels will contain around 34% to 38% oil. The Oil Mainly extracted through expellers followed by solvent