How much does the palm oil processing equipment cost?

- Type: palm oil production line machine

- Usage/Application: palm fruit, palm kernel

- Color: Customized according to customer. Requirement

- Raw material: peanuts

- Used for: vegetable oil manufacturing

- Product Function: cooking oil production

- Technology: negative pressure extraction

- Country: ethiopia

The cost of each stand-alone machine varies from $950-$29,000 depending on the processing capacity; the cost of a small palm oil production line of 1-5 tons per hour ranges from $100,000-$260,000; the cost of a large scale palm oil processing line of 10 tons per hour and above is more than $1,700,000.

Buy Cost Effective Palm Oil Production Equipment to Start

- Type: palm oil processing machine

- Automatic grade: Automatic

- Production capacity: 100%

- Weight: 1200 KG

- Dimension (L *W) *H): 2200*1400*2700mm

- Voltage: 115V/220V/380V

Palm Oil Production. Final Crude Oil and By-products of Palm Oil Production. With the help of palm oil production machine, palm oil is extracted from the fruit of the oil palm 'elaeis guineensis' and palm kernel oil is derived from the seed of the oil palm. Palm oil has been used as a primary cooking ingredient in most countries as it contains

Hongde Oil Machinery is leading professional manufacture and supplier of palm oil production line equipment includes palm fruit oil press, palm kernel oil extraction machine, CPO Refinery, and palm oil fractionation plant. Our team offer turnkey production solution for complete palm oil processing project with competitive cost!

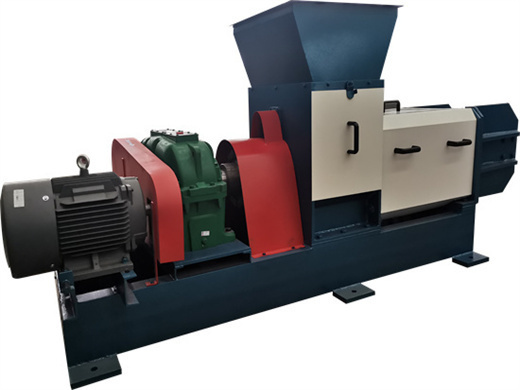

automatic palm kernel oil expeller machine price in Cameroon

- Usage: palm oil

- Production capacity (kg/h): 500 - 1000

- Outgoing inspection video: ProvidedPower (kW): 2.2kw

- Model: small

- Weight: 80 KG

- Main components: Bearing, motor , gear, sieve

On 27th July 2022, Cameroonian customer purchased 500kgph palm kernel oil processing machine, including a 500kgph palm kernel oil press machine and its accessories, 2tph roaster, bucket elevator, electric control. Palm Kernel Expeller Machine for Sales Factory Price. Palm kernel expeller machines are widely used to extract oil from palm kernel.

Main Station of Palm Oil Mill Process( Whether it is a small scale palm oil mill machine or large scale palm oil mill machine all includes the following station): 1) Palm fruit reception station; 2) Palm Fruit Sterilizing station; 3) Palm Fruit Threshing station; 4) Palm fruit Digesting & Pressing station; 5) Crude palm oil clarification station;

Palm Oil Processing Production Line

- Type: cooking oil extraction machine

- Production capacity: 20-2000T/day

- Power (W): 15 KW

- Voltage: 380V

- Dimension ( L*W) *H): standard

- Weight: 30 tons

Palm oil fractionation equipment can separate palm oil into soft fat and hard fat by controlling the cooling and crystallization process of palm oil. The melting point of hard fat is 50°C and the melting point of soft fat is 24°C. There are three common palm oil fractionation temperatures: 18°C, 24°C, and 36°C.

Palm oil production line. Hongde Oil Machinery is a leading company in the field of palm oil pressing and palm kernel oil processing and equipment, we can provide completely set of 5-120tph palm oil production line. Our company offers a range of products and services for the palm oil extraction, palm kernel oil extraction, crude palm oil

Hongde palm oil machine / FFB oil mill - Palm Oil Production Line

- Raw Material: palm

- Production capacity: 5TPD-100TPD

- Dimension (L*W*H): please refer to capacity

- Voltage: 220V/380V/440V/customer

- Weight: 30 KG

- Warranty: 1 year, 18 months

[rev_slider alias=”slider3″ slidertitle=”Slider 2″][/rev_slider] COMPLETE PALM OIL PRODUCTION LINEPalm Oil Engineering Project Specialist PALM OIL MILL PLANT Hongde palm machinery provides a range of palm oil making machines to extract oil from fresh fruit bunches of oil palm. The following is the typical palm oil manufacturing process which might be useful for new investors of […]

Multiple crystallisers are used in the series to maximise the use of filter through good planning. It is important to note that fractionation is quite modular technology and very often results in palm oil mill plant. Several water tanks (two to four), all at different temperatures, can be installed in order to maximise heat recuperation while keeping all cooling medium in a closed loop, but this can just as well be done with a single tank feeding chilled water to the crystallisers while steam is added to supply heat and normal cooling water is fed directly from a clean cooling tower. The fractional crystallisation of triglyceride oil is a slow process. The whole filtration and the squeezing operation can take from 30 to 90 minutes.