Crude palm oil refining methods and palm oil refining process

- Type: palm oil machine

- Usage/Application: palm fruit, palm kernel

- Production capacity: 1-500T/D

- Voltage:380V

- Weight: changed with capacity

- Dimension (L*W) *H): various with capacity

- Power (W): according to capacity

- Country: nigeria

Our company is specialized in palm oil refinery plant. We can provide the palm oil refinery plant from 1 ton to 1000 tons. In general, batch type palm oil refinery plant is with capacity 1-20TPD; The semi-automatic palm oil refinery plant is suggested with capacity from 20-50TPD; And continuous palm oil refinery plant is used for capacity above

Palm Oil Production Line. Tailor-made Palm Oil Mill Plant

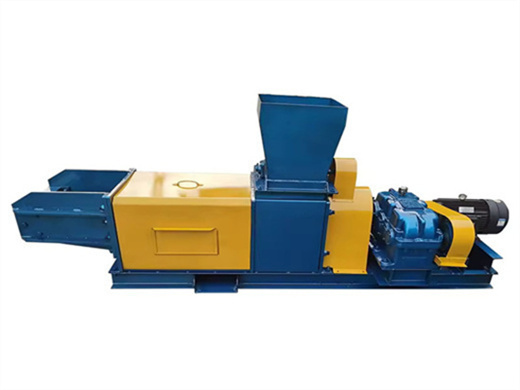

- Type: palm oil refinery machine

- Production capacity: 260-400(kg/h)

- Voltage: 380V, 380V

- Neme brand: YaYuan

- Main components: motor, PLC, bearing

- Dimension (L*W*H): 2050*1550* 1800mm<br /Weight: 2000kg, 2000kg

Palm Oil Refinery is an important process in the palm oil mill plant to ensure the quality and safety of palm oil. It’s recommended to refine crude palm oil through our palm oil refining machines to get high-quality palm oil that is easy to store and can priced high. Refined palm oil can be packed and labeled for the local or global market.

Oil physical refining process, also called as oil steam refining. During the degumming section in the palm oil milling plant, the gum will be removed from palm oil by utilizing phosphoric acid or citric acid. Next to bleaching section, the coloring matter and other metal ions will be absorbed or removed.

Everything You Need to Know About Palm Oil Refinery Process

- Usage: palm oil

- Production capacity: 1-100T/D

- Voltage: 380V/440v

- Weight: depends on capacity

- Dimension (L*W*H): depends on capacity

- Power ( W): 20-50KW

The crude palm oil is gathered from the mesocarp of the palm oil. However, the crude palm oil that has been extracted contains unwanted impurities and requires a refining process to partially or eliminate them to produce edible oil. In the current scenario, palm oil is widely used in tropical countries in South East Asia, Africa, and parts of

Continuous palm oil refinery (50-600tpd) 30TPD ,50TPD,100TPD,200TPD,400TPD (Suitable for industrial scale palm oil mill plant) Middle sized palm oil refinery plant. Recommed reading: 1-10tpd small scale palm oil refinery plant. Continuous palm oil refinery plant. Crude Palm Oil (CPO) is mainly further processed into edible oil for food purpose.

Palm Oil Machine - Palm Oil Production Line

- Type: cooking oil refining machine

- Production capacity: 100 to 500 tpd cooking oil processing

- Voltage: 220V /380 V/440 V

- Weight: 850 KG

- Dimension (L*W*H): 5432*2636*2345

- Power (W): 15 kW

The crude palm oil is refined by palm oil refining machine to remove impurities, sourness and color, and it can become clear edible oil in the supermarket; if the customer needs to produce industrial oil or cosmetic raw materials, the oil can also be separated by distillation equipment according to different melting points.

Reliable Manufacturer of Palm Oil Extraction and Refinery Equipment. As a professional manufacturer of palm oil batch refining plant, Our Machinery will customize the refining machines according to the customer's needs and will provide after-sales service such as installation and commissioning after the equipment arrives at the customer's factory, and will also train the operators to make the

Small Scale Palm Oil Refinery Machine Selection and Process

- Raw Material: palm

- Production capacity: 1TPD-1000TPD

- Power(W): 7.5kw

- Voltage: 220V/380V/440V

- Dimension ( L*W* H): 1200*400*900mm3

- Weight: According to the capacity of the baking press

Besides, for palm oil extraction machine, the oil yield and residual oil ratio are also key points to get more profits. Palm Oil Refinery Plant Cost; The price of palm oil refinery machine is also one of the main concerns of users, but it can only be a reference factor. Do not only look at the price and ignore the quality.

Henan Hongde Cereals and Oils Machinery Co., Ltd. has been rooted in grain and oil equipment manufacturing for 37+ years. It has a modern production base of 100,000 square meters, equipped with cutting-edge equipment such as laser cutting machines, fully automatic welding robots, CNC precision machining centers, and an annual production capacity of more than 200 large-scale edible oil