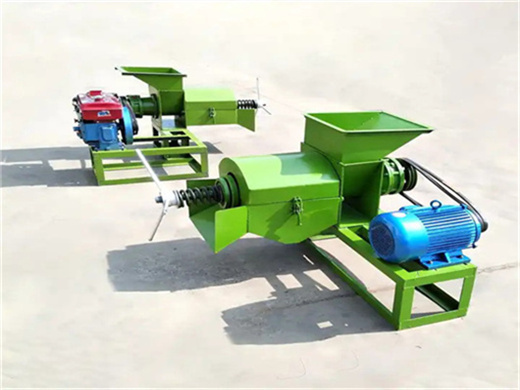

Edible Oil Dewaxing Fractionation Equipment For Edible Oil

- Type: cottonseed oil refinery machine

- Usage/Application: cottonseed

- New and latest technology

- Voltage: local voltage

- Weight: 100 kg - 1200kg

- Dimension ( length x width x height): 2000x1400x1850 mm

- Power (W): 5.5-15.5 kw

- Country: south africa

It is almost necessary to dewax the following products (such as corn oil, rice bran oil, sunflower oil, cottonseed oil, etc.). Oil fractionation is done by using the differences in glycerol’s melting point and solubility contained in various oils to divide the oil into solid fats and liquid oils.

Edible Oil Dewaxing Machine - Henan Hongde Cereals And Oils

- Type: cottonseed oil refinery machine

- Production capacity: 10-3000 tons/day

- Voltage: 220V/380V/440V

- Main components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Motor, Gearbox

- Weight: KG

- Dimension (L*W*H): according to customer

Edible Oil Dewaxing Machine. Overview. In short, oil dewaxing adopts forced cooling to make the high melting point wax solid oil precipitate out from liquid oil and then use the method of filtration or centrifugal separation to remove them. Different oils have different wax content.

Cotton Seed Oil Refinery Plant. Oil Refining is the progress of removing impurities such as phospholipids, FFA, pigment, and off-flavor in cruel oil before edible application. An oil refining machine is used for producing the first or second-grade edible oil. We are able to supply the professional oil refining plant and related oil refining

Edible oil refinery plant and edible oil refining process

- Usage: cottonseed oil

- Production capacity: 1-1000TPD

- Voltage: 220V/380V

- Weight: 30 tons

- Dimension (L*W*H): 1.5*2.6*3.6 M

- Power ( W): 5.5 kW

Henan Doing Mechanical Equipment Co., Ltd's product range includes a wide range of edible oil refineries and vegetable oil refinery plant, which can be divided 1-20tpd batch type edible oil refining machine, 10-50tpd semi-continuous edible oil refinery plant and 30-1000tpd full-continuous edible oil refinery plant by type.

Fractionation and Refining Crude Cottonseed Oil. 30ton/day Cottonseed Oil Refinery Plant. Refining crude cottonseed oil to produce edible / cooking oil. It involves bleaching, De-acidification, deodorization, and degumming. Fractionation can get solid and liquid oil through solid and liquid separation and cooling crystallization.

What is dewaxing process during vegetable oil refinery?

- Type: cooking oil refining machine

- Production capacity: 5TPD

- Dimension (L*W*H): 1.45*0.9*1.1m

- Voltage: 220v

- Weight: 300KG

- Main components warranty: 6 months

So dewaxing process is also called winterization. Henan Doing Company adopts the way of refining first and dewaxing last. So the crude vegetable should be refined in crude vegetable oil refinery plant, and then be pumped into dewaxing workshop. Dewaxing process during vegetable oil refinery has three main steps. Dewaxing process flow chart. 1.

Cottonseed oil refinery plant is a necessary part of cottonseed oil mill plant. Because crude cottonseed oil cannot be directly used by human if without any farther refining process. Cottonseed oil is extracted from cottonseeds, whose fatty acid profile generally consists of 70% unsaturated fatty acids and 26% saturated fatty acids.

Edible oil refinery plant manufacturer supplies oil refining

- Raw Material: cottonseed oil

- Press Series: Second

- Function: Edible Oil Manufacturing

- Customized: Customized

- Raw material: sunflower, kitchen, etc.

- Transportation package: in wooden packaging, according to customer specifications: various

30 tons semi-continuous edible oil refining machine delivery video; 2t/d electric heating cooking oil refining equipment delivery video; 1tph cottonseed oil refining project video in Uganda; Cottonseed oil refining machine video; Small scale cooking edible vegetable oil refining and filling machine running video; Read more>>

It improves the oil's clarity and brightness by removing solids —saturated glycerides or waxes— that are visible at ambient or low temperatures. KMEC's oil dewaxing machinery reduces the content of these solids to less than 10 parts per million, a level necessary for proper stability. Vegetable Oil Refinery