Supply Chain Management - SD Guthrie International

- Type: palm oil mill

- Usage/Application: palm fruit, palm kernel

- Production capacity: 100-6000 kg/hour

- Voltage: 220 V

- Main components: engine

- Weight: 12 kg

- Dimension (length x width x height): 390*150*292 mm

- Country: nairobi

We assess traceability to mill based on volumes supplied to each of our refineries and palm kernel crushers for the following categories: Crude Palm Oil (CPO); Palm Kernel (PK); Crude Palm Kernel Oil (CPKO); and ; Refined Palm Product. A mill is deemed to be traceable if the information listed below is complete: Parent Company name; Mill Name

Palm Kernel Oil Plant - Oil mill

- Type: palm oil refinery machine

- Production capacity: 1-100T/DAY

- Voltage: 220 V

- Main components: Motor

- Weight: 240 kg

- Dimension (L*W*H): 1160*820*1260

We offer complete palm kernel oil production lines and palm fruit oil production lines to meet your large volumes of palm oil production needs. Our patented palm oil processing technology transforms palm kernels into high-quality stable palm kernel oil through an efficient, meticulous, seamless, and sustainable process.

Palm oil and palm kernel oil can be refined and fractionated into, amongst others, olein, stearin and palm mid fractions for different applications. The applications of palm oil are far ranging. In the food sector the principal uses are in cooking oils and frying fats; margarine and spreads; shortenings; confectionery and bakery fats; ice cream

Processing - Wilmar International

- Usage: palm oil

- Certification: ISO, CE, BV

- Product type: automatic oil machine

- Production capacity: 20-2000TPD

- Residual oil in flour: ≤ 1%

- Voltage: 220/380 Or other

From refining crude palm oil, we produce Refined, Bleached and Deodorised (RBD) palm oil which can be further processed into RBD palm olein and RBD palm stearin. RBD palm olein has a lower proportion of saturated oil than RBD palm stearin and is primarily used as cooking oils and in industrial frying of processed foods.

We operate two state-of-the-art palm oil refineries, Unitata Berhad & UniFuji that are responsible for value-adding our Certified sustainable crude palm oil and crude palm kernel oil into high-quality processed products for customers around the world. Our refineries operate based on Global Food Safety Initiative (GFSI) standards and are mainly

Caraga Oil Refining

- Type: cooking oil refining machine

- Method: Physical treatment

- Blender powder: 0.1-1.5

- Screw shaft power: 0.1-4.5

- Total dust: 0.2-6.0

- Cbm: 1-21

Equipped with this expertise and experience, the company has become the leading producer of palm oil and palm oil products in the country. Boasting a daily rated capacity of 150 metric tons for refining, too metric tons for fractionation, and 50 metric tons for palm kernel crushing.

Agricultural Production And Processing. Extraction of crude palm kernel oil (CPKO) and palm kernel cake (PKC) Processing of Refined Vegetable Oil

Palm Oil Production Line - Oil mill

- Raw Material: palm

- Production capacity: 1tpd-1000tpd

- Dimension (L*W*H): please refer to capacity

- Voltage: 220V/380V/440V

- Weight: KG

- Warranty: 1 year, one Year

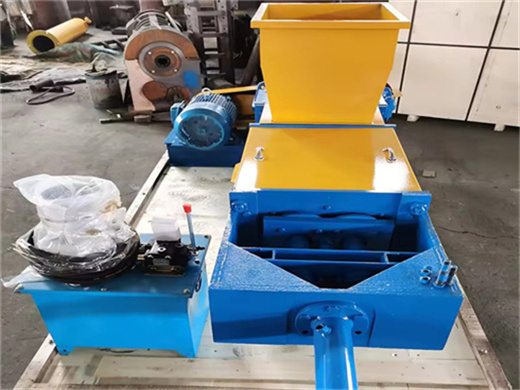

The commonly used palm oil press machine is a double screw expeller. The pressing process maximizes palm oil extraction from the pulp, but the kernels cannot be broken because the crushed palm kernel oil will contaminate the crude palm oil and affect the quality. Using two or more pressing processes can effectively reduce the cracking rate of nuts.

Palm oil processing and palm oil mill Palm oil is an edible vegetable oil derived from the mesocarp (reddish pulp) of the fruit of the oil palms. It is naturally reddish in color because of a high beta-carotene content. Palm mesocarp oil is 49% saturated, while palm kernel oil is 81% saturated fats.