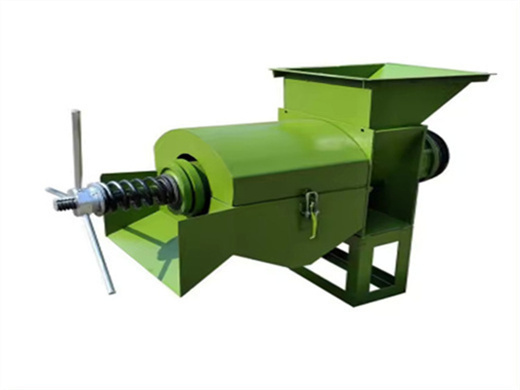

Small Size Peanut Oil Manufacturing Machine in Cameroon

- Type: peanut oil extraction machine

- Usage/Application: peanut, groundnut

- Production capacity: 1tpd

- Voltage: 380v

- Certification: CE

- Weight : 760kg

- Dimension (L*W*H): 200*1500*1200

- Country: cameroon

Small Peanut Oil Manufacturing Machines Ready to Cameroon. Cameroon Peanut Production. Peanut farming began in South America, dating back 7,500 years. In the first century, the plant reached Mexico and expanded to North America, China and Africa. Peanut is a common crop in the world. Cameroon is one of the Top 10 peanut production country.

Peanut Oil Production Line,Peanut Oil Pressing Plant - Oil mill

- Type: peanut oil refinery machine

- Power (W): 4.5

- Voltage (V): 5

- Capacity: 101-200 ml

- App controlled: NO

- Private mold: Yes

Peanut Oil Refining Process: Degumming: The crude peanut oil is mixed with water and heated to remove phospholipids and gums. Neutralization: An alkaline solution (sodium hydroxide) is added to neutralize free fatty acids, forming soapstock, which is then separated. Decolorization: Removes pigments and other coloring agents using bleaching clay.

4. Pressing and Refining: Pre-treated peanut flakes are pressed by the oil press to obtain crude peanut oil. Depending on the required quality grade of the peanut oil, corresponding refining equipment and processes are configured. The crude oil is refined to remove impurities, resulting in finished peanut oil. This is the peanut oil extraction

Formation and reduction of 3-monochloropropane-1,2-diol

- Usage: peanut oil

- Production capacity: 40-50 kg/h

- Voltage: 380 V

- Main components: Motor

- Weight: 200 KG

- Dimension (L*W* H): 950*400*850

As shown in Table 1, deodorization was a critical factor that influenced the formation of 3-MCPD esters in peanut oil among the refining steps. In order to examine if there were any differences in the contents of 3-MCPD esters between different ways of oil production, hot pressing and solvent extracting were introduced for crude oil production.

Next, I will introduce the refining process of peanut oil in the order of the work sections. Crude peanut oil refining machine. Step1. Degumming. In this step, we add hot water to dissolve colloidal impurities in crude peanut oil to remove excess phospholipids and make the color more vivid and obtain purer peanut oil; Step2. Deacidification

Fully Automatic Groundnut/Peanut Oil Production Line

- Type: cooking oil refining machine

- Keyword: AB parts glue encapsulation machine

- Glue speed: 15g/s

- whatsapp: +86 134 2516 4065

- Machine type: Automatic control

- Machine Suitable material: silicone, epoxy, polyurethane resin

Peanut oil sold on the market can be divided into two categories: pressed peanut oil and extracted peanut oil according to the process. The pressing process adopts the principle of physical extrusion to squeeze the oil out of the oil. There are no additives during the pressing process, retaining the inherent flavor and flavor of the peanut oil.

But the widely used commercial oil extraction methods for groundnut oil production for commerical or industrial use are solvent extraction and mechanical pressing due to the high efficiency of oil production, scientific oil extraction process and relatively cost-effective oil extraction equipment. Here just introduces the basic groundnut oil

The Definitive Guide to Peanut Oil Refining Process

- Raw Material: peanut

- Production capacity: 20-2000TPD

- Power (W): Standard

- Voltage: 380V

- Dimension (L*W*H): standard

- Weight: standard

The peanut oil refining process is a critical process to transform crude peanut oil into a high-quality, edible product. (Read more: how to make peanut oil. >>) The refining process consists of four key stages: degumming, deacidification, decolorization, and deodorization. The refining process can be conducted using batch-type, semi-continuous

Peanuts occupy a large proportion of the edible oil market. The pressing process is a traditional and common peanut oil processing method, but it cannot fully extract the oil, leaving a relatively high residual oil in the cake. This has little impact on small and medium-sized oil mills, but for large edible oil processing plants, it is crucial to fully utilize oil resources to reduce production costs and increase profits, allowing the oil plant to stand firm in the fierce market competition.