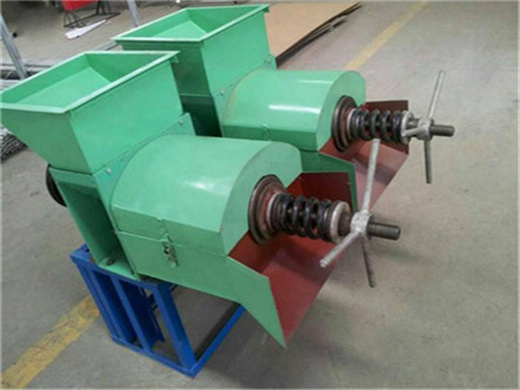

Sunflower Oil Refinery Plant Process - Oil Expeller

- Type: sunflower oil refinery plant

- Usage/Application: sunflower

- Production capacity: hemp seed oil press

- Voltage: 220V/380V/440V

- Weight: 850 KG

- Dimension (L*W*H): 5432*2636*2345

- Power (W): depends on capacity

- Country: indonesia

One of the factors of sunflower oil is its typical properties of wax. Sunflower oil contains wax from 1000 ppm to 1500 ppm based on the variety of seeds. The wax give haziness to the oil after refining. Hence it becomes necessary to remove the wax to avoid haziness of the oil and also stickiness of the Oil.

Sunflower Oil Refining Process Essentials for Optimal Effects

- Type: sunflower oil refinery machine

- Production capacity: 98%

- Voltage: 220V/380V/440V

- Weight: 30 tons

- Dimension (L*W*H) : 48m*12M*15M(30TPD)

- Power (W): 22kw

Start Profitable Sunflower Oil Refining Plant Supported by Professional Techniques. This article focuses on the proven sunflower oil refinery process, providing relatively accurate process parameters, effectively improving the efficiency of sunflower oil refining, reducing oil refining losses and lowering production costs.

Sunflower oil refinery plant: Machines used in large scale sunflower oil refinery plant. Sunflower oil refinery plant has three types, and their processes are different. If you want to know the details, please read the following passages. a. batch type sunflower oil refining machine. b. semi-continuous sunflower oil refinery plant

What Are Sunflower Oil Refining Process Techniques?

- Usage: sunflower oil

- Production capacity: 80%-100%

- Voltage: 380V/50HZ, 480V is optional

- Main components: Motor

- Weight: 260 KG

- Dimension (L*W*H): 1900*840 *2000mm

Semi-continuous Refining. Semi-continuous refining processing line serves a wide range of small to medium-sized sunflower oil plants. Through years of research and development, semi-continuous refining has become better suited for small to medium-tonnage(10-50ton) sunflower oil refining prodcution.

The first step in starting a sunflower oil refinery plant is investment in oil refinery machines. These sunflower oil making machines not only determine production efficiency, but also have a direct impact on product quality and operating costs. Selecting efficient and reliable oil refinery equipment is critical to controlling long-term

The process of chemical refinery for sunflower crude oil

- Type: cooking oil refining machine

- Voltage: 380

- Dimension (L*W) *H): Standard

- Power (W): Standard

- Weight: Standard

- Certification: ISO9001

Sunflower oil machine prices, also known as cold press oil machines, vary according to oil squeezing machines with different volume measurements. For example, the price variability increases depending on the volume of the cold press machine you want to choose for the oil machine. From black cumin to sesame seeds, from flaxseed to dried nuts and from sunflower seeds to seeds, you can obtain sunflower oil by cold pressing.

Refined Sunflower Seed Oil sunflower seed oil refining process. Sunflower oil refining methods can be roughly divided into the mechanical method, chemical method, and physicochemical method. The operation of the sunflower oil refining machine is divided into the following four steps. 1.

10-50tpd sunflower edible oil refinery plant in indonesia | oil

- Raw Material: sunflower

- Production capacity: 500 L/H

- Dimension (L*W*H): 1984*694*1153

- Voltage: 380v 50hz

- Weight: 1300 KG

- Main components: Motor

ABC Machinery is leading oil processing machine manuafacturer and supplier in China. We offer various sunflower oil making machine types at factor price. Sunflower oil making business is profitable around the world, especially in China, India, South Africa, Tanzania, Ukraine, Kazakhstan, Brazil, and more. More and more people can't find out where to buy the most suitable and cost-effective sunflower oil making machine for their business. ABC Machinery is definitely your reliable supplier.

We design and develop complete integrated refinery plant and system specially for sunflower oil. Sunflower oil is considered to be one of the most stable oils for frying. The demand for oils with a lower degree of unsaturation than those of traditional oils has significantly increased the availability of oils of high thermostability.