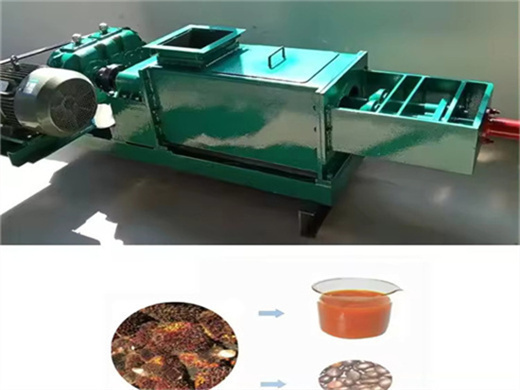

6yl 120b multi function combined oil press machine in rwanda

- Type: palm oil press

- Usage/Application: palm fruit, palm kernel

- Automatic grade: Semi-automatic

- Production capacity: 1TPD-1000TPD

- Dimension (L*W*H): 46*32*36cm

- Power (W): 5.5 kW

- Voltage: 220V

- Country: rwanda

6yl 120b multi function combined oil press machine in rwanda. Use: edible oil; Type: edible oil press machine; Production Capacity: according the capacity; Model Number: 1-200T/D; Voltage: 380V or 440 V; Power(W): according the capacity; Dimension(L*W*H): according the capacity; Weight: according the capacity; Certification: BV and CE

6YL-120 oil press - BTMA

- Type: palm oil processing machine

- Production capacity: 100% cooking oil extraction machine

- Voltage: 220V/380V

- Weight: 1000KG

- Dimension (L*W*H): 900*850*1550mm

- Power (W): 1.5 kW

6YL-120 OIL PRESS. Labor Saving: the same output can save 62% of the labor force, and one to two people can organize production. High Oil Yield Rate: compared with old and traditional oil press, the oil output rate of our oil press machine can be 5 to 8 percentage points higher.

6YL-120 oil press machine 6YL-120 oil press machine can pressed all kinds of plant oil materials such as peanut, soybean, rapeseed, cottonseed, sesame, olive, sunflower, coconut,etc. Suitable for medium-small scale oil factory and private user.

6YL-120 oil press machine|manufacturers 6YL-120 oil press

- Usage: palm oil

- Production capacity: 200 tpd oil press machine

- Voltage: 220V/380V/440V

- Weight: 850 KG

- Dimension (L*W*H): 5432*2636*2345

- Power (W): depends on the capacity

6YL-120 oil press operating principle: 1.When 6YL-120 oil press machine is on work, material enters the extruding chamber from the hopper and then moves forwards by the rotating pressing screw and is pressed. 2. Under high temperature condition in the chamber, there is quite strong friction among press screw, chamber and the oil materials. 3.

Working Princciple and Structure. 1.Working principle:This oil mill machine uses the poer of the space change for the material in the chamber and the driving force from the scre shaft as well as the resistance from the tooth curve in the pressing ring.The friction force from material pressing produces big pressing power,then oil-segregates from the material and discharges from the pressing bar

Screw Expeller,Oil Screw Press,Screw Oil Press,Jatropha Oil

- Type: cooking oil extraction machine

- Production capacity: 10T/24h

- Voltage: 380V

- Main components warranty: 1.5 years

- Weight: 80600kg

- Dimension (L*W*H): 2005*1610*2010mm

6YL-120 oil expeller is an advanced oil screw press, characterized by its simple design, easy to use, wide suitability and continuous operation, high productivity and high oil output rate. Moreover, this screw expeller can be used for various raw materials, such as ground nuts, soybeans, rape seeds, cotton seeds, sesame seeds, sunflower seeds

ZY / ZX28 spiral oil press is a large continuous oil press equipment, through the 09001-2000 Quality System Certification, Suitable for cottonseed,rapeseed, castor, sunflower seeds, peanuts and other high oil content of the press oil.It has the characteristics of large processing capacity, small power consumption, low operating cost, loose and not broken cake structure, easy solvent

Economic and Practical Palm Kernel Oil Press

- Raw Material: palm

- Voltage: 220V/380V/440V

- Dimension (L*W*H): 48m*12M*15M(30TPD)

- Power (W): 22kw

- Weight: 30 tons

- Certification: ISO CE

Hongde Machinery a specialized company with more than 20 years of experience in manufacturing palm oil equipment and constructing the whole process of mills.The quality of our equipment meets the highest standards, ensuring that your production line runs efficiently and reliably. In addition, we offer a full range of services from planning and design to equipment manufacturing and plant construction. With our industry-leading experience, we provide our customers with excellent solutions to help the palm industry take off.

6YL-120 oil press machine oil making press adopts the principle of multi-stage gradual compression to increase the pressure in the barrel quickly and thus maximize press oil out. Oil output rate is greatly improved for the unique design of the oil guide groove in the barrel. It helps separate oil and cake rapidly to avoid oil absorbed by dry meals.