Cottonseed oil mill plant manufacturers

- Type: cottonseed oil extraction plant

- Usage/Application: cottonseed

- Production capacity: 3 tons/day

- Voltage: 380V/440V

- Warranty: One year warranty against manufacturing defect.

- Weight: 0 KG

- Dimension (L*W*H): Depends

- Country: south africa

Cottonseed Oil Extraction Process. Our cottonseed oil extraction plant uses a well-structured process to extract premium oil from cotton seeds. With precise cleaning, dehulling, and solvent extraction, we ensure maximum yield and purity for various industrial and edible applications.

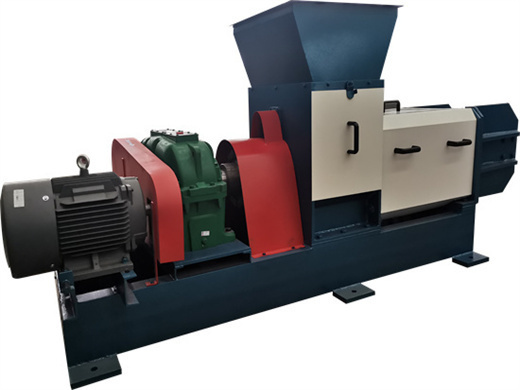

Cottonseed Oil Mill Plant

- Type: cottonseed oil processing machine

- Production capacity: 250-300 KG/H

- Voltage: 380V

- Weight: 2200 kg

- Dimension (L*W*H): 2000x1200x2500 mm

- Power (W ): 3KW

Cottonseed oil is extracted from the seeds of cotton plants. Refined cotton seed oil is edible. India, China, Pakistan, USA and Brazil are among the top producers of cotton seed oil in the world. Let us now know about the various aspects of cottonseed oil plant - it's manufacturing process, world market status and other features.

The crushing of cotton seed to produce oil was documented in very old Hindu medical books. Later years a Chinese cotton seed oil production was noticed with wedge systems. Cotton seed oil is very dominant vegetable oil in United States of America for almost 100 years. It is highly dominated and principal raw material for vegetable oil products.

Cottonseed Oil Extraction Plant

- Usage: cottonseed oil

- Production capacity: 20tpd

- Voltage: 220V/380V/440V

- Main components: motor, pressure vessel, pump, PLC, others, gears, motor, gearbox

- Weight: 30 tons, depends on capacity

- Dimension (L*W*H): 1700*1300*1750mm

The miscella is pumped into the hydrocyclone to remove the fines and then the miscella enters the miscella tank in the cottonseed oil extraction plant. Wet Meal Desolventizing. The wet meal from the oil extractor enters the DTDC desolventizing the cottonseed oil extraction plant.After pre-desolventizing, desolventizing, drying, and cooling, the

Undecorticated Cottonseed obtained after Delinting process can be used as a raw material for Cottonseed Oil Extraction Plant. Cottonseed contains 18 – 20 % oil content. After a single stage pressing, about 6 – 7 % residual oil is left in the cottonseed meal which is an excellent source of Cattle Feed. The working principle of the cotton

Steps of Cottonseed Oil Processing Process - Oil Mill Machinery

- Type: cooking oil extraction machine

- Production capacity: 100% cooking oil making machine

- Power (W): Depends on capacity

- Voltage: local voltage

- Dimension (L*W*H): 2400x1500x1950mm

- Weight: 30 tons

Within the cottonseed oil processing plant, oils extracted from cottonseed must be refined to remove gossypol, a naturally occurring toxin that protects the cotton plant from insect damage. Cottonseed meal is a good source of protein. It is the byproduct remaining after cotton is ginned and the seeds crushed and the oil extracted.

Cottonseed Oil Decolorization. The main purpose of bleaching is to remove pigments from cottonseed oil to improve the color and appearance of the oil. First, we need to heat the degummed (or deacidified) cottonseed oil to 110-120°C. Second, add 0.5-1.5% of an adsorbent such as activated carbon or clay.

Complete Cotton Seed Oil Processing Plant

- Raw Material: cottonseed oil

- Production capacity: 98%

- Power (W): 22kw or according to cooking Capacity of cooking oil making machine

- Voltage: 220V/380V/440V

- Dimension (L*W*H): 2000x1400x1850 mm or according to capacity of cooking oil making machine

- Weight : 30 ton cooking oil making machine

After the mixed oil is evaporated and stripping by the mixed oil treatment system, the solvent is vaporized and discharged to obtain cottonseed oil. Cotton Oil Extraction Plant. Cottonseed Oil Refining; Both the pressed cottonseed oil and the extracted cottonseed oil need to be transported to the oil refinery plant for further treatment. The

Cottonseed could either be processed by the traditional crude method of crushing seed without Delinting in un-decorticated form or by scientific processing used for Cotton Seed Processing, which involves removal of De-linters, decortication, separation of hull, expelling, solvent extraction and refining of oil. Scientific processing of Cotton