Palm Kernel Oil Extraction: Traditional and Modern Methods

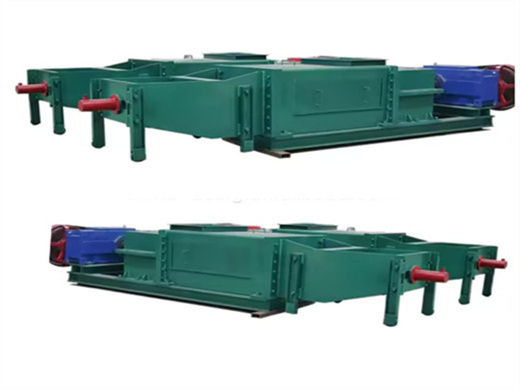

- Type: palm oil extraction equipment

- Usage/Application: palm fruit, palm kernel

- Weight (KG): 7845

- Main components : PLC

- Process: Co2 Extraction Machine/Equipment with Supercritical Fluid

- Material: 303/316

- Function: Extraction machine

- Country: zambia

Explore palm kernel oil extraction methods, from traditional cold pressing to modern solvent extraction. Compare yields, costs, and sustainability to find the best process for your needs. If you want to extract palm kernel oil (PKO), you have several options. Traditional methods like cold pressing and roasting require time and effort but

5. PALM KERNEL OIL EXTRACTION - Food and Agriculture Organization

- Type: palm oil processing machine

- Voltage: 380 V

- Appearance: Horizontal

- Customized: Customized

- Press Series: Quarter

- Press Materials: Jatropha Oil Extraction Machine

5.3 Traditional method of palm kernel extraction. Palm kernel extraction is a specialised operation undertaken by a completely different set of processors. They are usually better organized as a group and are not as dispersed as palm oil processors. The kernel processors have to go around the palm oil processors during the peak season, when

oil from the palm fruit kernel. The extraction of oil from the hard palm kernel is more difficult and less efficient than from pulpy 'flesh. Palm kernel oil has a similar uses to coconut in both the edible and non edible fields, because of their similarity in composition and properties. It is often used in the manufacturing of various

Kembara Insan / Engineer's Blog: Palm Kernel Oil Extraction

- Usage: palm oil

- Production capacity: 10% residual oil cake

- Voltage: manual

- Main components: Motor

- Weight: 320 kg

- Dimension (L*W*H): 320*700*850mm

The traditional oil extraction method is to fry palm kernels in old oil or simply heat the dried nuts. The fried kernels are then pounded or ground to a paste in a motorised grinder. The paste is mixed with a small quantity of water and heated to release the palm kernel oil. The released oil is periodically skimmed from the top.

It is one of the best oils. Palm kernel oil is different from palm oil, which is obtained from the flesh of the fruit. The design objective in this case is to redesign and fabricate a palm kernel oil extraction plant (mechanical) that will produce 200kg of palm kernel oil per day using palm kernel. In the extraction of palm kernel oil, many

EXTRACTION AND PHYSICO-CHEMICAL CHARACTERIZATION OF PALM

- Type: cooking oil extraction machine

- Production capacity: 1-500T/D

- Place of Voltage: 220V-480V

- Weight: 1050 KG

- Dimension (L*W*H): 430*230*350

- Power (W): different

quality considering the peroxide value of 4.1meq/kg. The extracted palm kernel oil was soluble in esters and insoluble in water. Colour of the extracted palm kernel oil was yellow; the odour was a pleasant one. The extracted oil is suitable for soap making. Keywords: Extraction, Palm, Kernel, Oil, Vharaterization. I. INTRODUCTION

The use of mechanized extraction of palm kernel oil results in faster oil production, higher daily processing capacity, and more palm kernels can be processed in a shorter period of time. Through the comparison of the above mechanized and the traditional palm kernel extration method, we can clearly find the advantages of mechanized production

Palm Oil Extraction Process, Methods, Steps | Agri Farming

- Raw Material: palm

- Production capacity: 5TPD-100TPD

- Dimension (L*W*H): 400*500* 850 mm

- Voltage: 220V/380V

- Weight: 520 KG

- Main components: motor, pressure vessel, PLC

Palm oil extraction process: Palm oil is extracted during a carefully monitored series of phases that seeks to make sure that the end product is highly appealing. Palm oil extracting plant generally begins with the harvesting of the fruit. This is the process of palm oil physical extracting (screw pressing) and field factors that determine

To process palm oil, begin by harvesting fresh palm fruit bunches and separating the fruit from the bunches. Then, sterilize the fruit, extract the oil by pressing or using a mechanical extraction method, and finally, refine the oil through processes such as clarification and purification to obtain high-quality palm oil.