Cottonseed Oil Production Line

- Type: cottonseed oil equipment

- Usage/Application: cottonseed

- Production capacity: 100kg/h-550kg/h

- Voltage: 380V

- Weight: 1200 kg

- Dimension (L*W*H): 1700*1100*1600 mm

- Power (W): 5.5 ~ 11 kW

- Country: nairobi

The deodorization process can not only remove the odors from crude cottonseed oil, but also improve smoke point, flavor, steadily and quality of final oil. At last, cottonseed oil refining has a special process -- cottonseed oil fractionation process. It is to seperate the solids and liquids in cottonseed at a specific temperature.

Oil Extraction Plants

- Type: cottonseed oil refinery machine

- Production capacity: 1-1000TPD

- Voltage:220V/380V/415V

- Weight: According to the actual situation

- Dimension (L*W*H): According to the capacity

- Power ( W): 1-30kw

The lint obtained as a byproduct is further subjected to ginning into bales for sale. (Related Post: Cottonseed Oil Mill Project Cost >>) Our cottonseed oil machines are lined with FRP for better corrosion resistance and provide major advantages of high dehull rate and high production capacity. These machines have made the process of obtaining

Cottonseed oil is extracted from the seeds of cotton plants. Refined cotton seed oil is edible. India, China, Pakistan, USA and Brazil are among the top producers of cotton seed oil in the world. Let us now know about the various aspects of cottonseed oil plant - it's manufacturing process, world market status and other features.

Refined Cotton Cellulose Production Line

- Usage: cottonseed oil

- After-sales service: free spare parts

- Voltage: 220V

- Press Series: Second

- Press Materials: Sunflower, all seeds

- Appearance: Vertical

Dingsheng Machinery has cooperated with refined cotton producers since the beginning of the industry. Our experience has been applied to smart cottonseed oil and cottonseed deep processing solutions for the entire supply chain - cottonseed oil refining, cottonseed oil hydrogenation, refined cotton cellulose, cottonseed protein and more.

The production of our refined cottonseed oil begins with the harvesting of the cotton plant. After the fibers have been separated for use in the textile industry, the seeds remain. These seeds are cleaned and freed from foreign matter and cotton lint. Next, the seeds are ginned and hulled, whereby the hulls are removed and used as a by-product.

Complete Cottonseed Oil Production Lines. Cottonseed Oil

- Type: cooking oil refining machine

- Voltage:Standard

- Dimension (L*W*H):Standard

- Power (W):Standard

- Weight:Standard

- Certification:CE ISO

For large cottonseed oil production lines with capacities of over 30 TPD, the solvent extraction method is usually adopted working together with cottonseed oil pre-press to maximize the oil yield. The large cottonseed oil production line includes a cottonseed pretreatment and pre-pressing workshop , a cottonseed cake solvent extraction workshop

Refined clear cottonseed oil without gossypol and other toxic substance can be used as cooking food. Due to clear cottonseed oil contains a large quantity of linoleic acid, it can prevent the content of cholesterol rising, maintain human body health. Human body consumption of cottonseed oil is up to 98%. Cottonseed Oil Needs Refining

Cooking Oil Refining Plant. Edible Oil Refining Equipment

- Raw Material: cottonseed oil

- Production capacity: 10T-3000T/D

- Power (W): 10-50kw

- Voltage:220V/380V/440V

- Dimension (L*W) *H):1200*400*900mm3

- Weight:According to oil refining capacity

Capacity Range: Our refinery plants range from 2 to 5,000 tons per day (TPD), accommodating various production scales.; Custom Solutions: We provide tailored refining solutions based on the specific characteristics of different crude oils, such as palm oil, soybean oil, sunflower seed oil, peanut oil, rapeseed oil, corn germ oil, cottonseed oil, linseed oil, and rice bran oil.

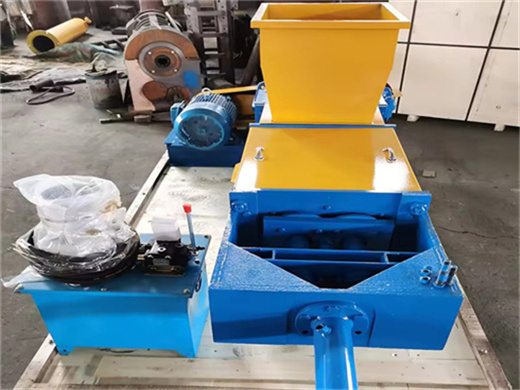

Cottonseed oil production line consists of cottonseed oil pretreatment and oil pressing machines and cottonseeds oil refinery plant and solvent extraction for large scale cotton seeds oil factory. Among them, cottonseed oil pretreatment machines include cleaning machines, husking machine, kernel & shell separating machine, flaking machine, cooking machine. And cottonseed oil pressing machine has two kinds: oil press machine and oil pre-press machine. The later one is used to get part of oil from cottonseeds, and then the pressed cake will be sent into cottonseed solvent extraction plant.