Cooking Oil Refining Plant. Edible Oil Refining Equipment

- Type: peanut oil refinery plant

- Usage/Application: peanut, groundnut

- Production capacity: 100% oil refining plant

- Voltage: 220V/380V/440V

- Weight: 2000kg

- Dimension (L*W*H): 1500*1600*2500mm

- Power (W): 18.5 kw

- Country: lagos

Capacity Range: Our refinery plants range from 2 to 5,000 tons per day (TPD), accommodating various production scales.; Custom Solutions: We provide tailored refining solutions based on the specific characteristics of different crude oils, such as palm oil, soybean oil, sunflower seed oil, peanut oil, rapeseed oil, corn germ oil, cottonseed oil, linseed oil, and rice bran oil.

mini small peanut oil refinery plant machine in lagos

- Type: peanut oil refinery machine

- Production capacity: 80-5000 kg/h

- Voltage: 220 V

- Warranty: 1 year, 1 year

- Weight: 1100 KG

- Dimension (L*W*H): can be customized

This is the peanut oil extraction process. The configuration of the peanut oil production line needs to consider various factors such as the size of the investor's plant, production capacity, quality, and budget. Equipment configuration plans and quotations are provided as needed. The manufacturer has been focusing on the research and production of oil machinery for many years, producing high-quality equipment with a complete range of types and models, offering customized services and production line configurations as needed.

Please note: for self-employed entrepreneur and small-business owner, 1-10 tons/day batch type oil refinery production line is their best choice to refine crude oil into the first or second grade edible oil(e.g. peanut oil, rapeseed oil, tea seed oil, soybean oil, sunflower oil, etc.) with features of multi-purpose, easy transportation, small

Peanut Oil Production Line,Peanut Oil Pressing Plant

- Usage: peanut oil

- Production capacity: 5TPD

- Voltage: 220V/110V

- Oil type: Cooking oil

- Main components: Motor

- Dimension (L*W*H): 42 * 16 *32cm<br /Weight: 11 KG

Peanut oil (groundnut oil), as a kind of light yellow transparent edible oil with a pleasant fragrance and good taste, is relatively easy to digest. Peanut oil contains more than 80% unsaturated fatty acids (including 41.2% oleic acid and 37.6% linoleic acid).

Peanut oil pressing, also called mechanical pressing method, refers to the use of mechanical forces to squeeze oil out of peanut. The mechanical oil pressing method uses the power which is generated from the gradual reduction of the volume between the squeezed screw and the pressing chamber, as well as the power generated by the friction between the material and the machine to extrude the oil inside pretreated peanut.

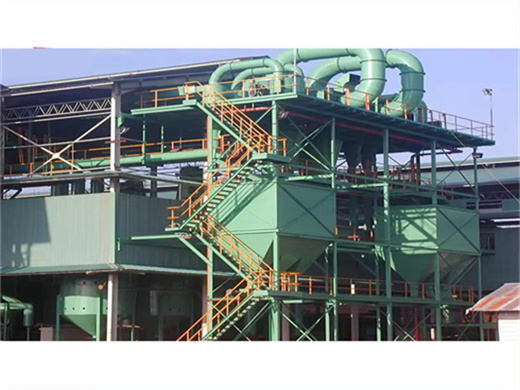

Oil Refinery - Edible Oil Refinery Technology and Equipment

- Type: cooking oil refining machine

- Production capacity: 1-100t/d

- Voltage: 220V/380V/440V

- Weight: Depends on capacity

- Dimension (L*W*H): Depends on capacity

- Power ( W): 50kw

In CHEMSTA Edible Oil Refinery production lines, we make use of Siemens PLC control system, which is one of mainstream automatic control systems in today`s industry. The efficient, stable and advanced DCS control system consists of operation station, control station and communication network.

Especially, a mini complete oil extraction and refinery plant can process various oilseeds into edible oils, including groundnut/peanut, sunflower seeds, coconut/copra, cottonseeds, mustard seeds, corn germ, rice bran, palm kernel, sesame seeds, south africa seeds, soybean, and more, which provides more flexibility for your mini oil mill business.

Groundnut Oil Refining Plant | Peanut Oil Processing Plant

- Raw Material: peanut

- Weight (KG): 7845

- Function: Extraction machine

- Main components : PLC

- Material: 303/316

- Process: Co2 extraction machine/equipment with supercritical fluid

Apart from its alluring strong aroma and universally liked peanut flavour, the all-purpose cooking oil brings multiple health benefits to the table. By being an active agent in lowering cholesterol and especially the bad cholesterol, it is being accepted gleefully across the globe.

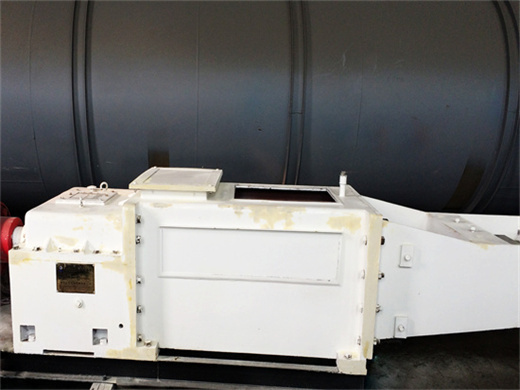

Peanut Oil Extraction: Customers can choose rotocel extractor or drag chain extractor based on their requirements. For different raw materials, the grid tray clearance and grid tray arrangement will be properly adjusted to ensure that the Peanut Oil residues in the seed meal is at a minimum.