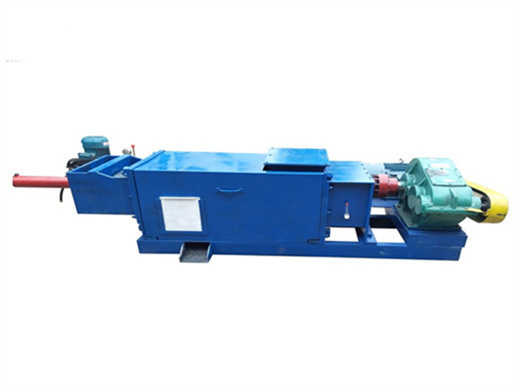

Copra Grinder Machines for pressing cold coocnut oil

- Type: coconut oil machine

- Usage/Application: coconut, copra

- Production capacity: 80-5000kg/h

- Voltage: 220V380V

- Main components: motor, container pressure, PLC

- Weight: 300 KG

- Dimension (L*W*H): 1.2 *0.78*1.1 m

- Country: nairobi

Copra grinder machines epitomize technological ingenuity, offering a gateway to enhanced efficiency, superior quality, and sustainable practices in coconut oil extraction. By embracing innovation and leveraging advanced machinery, manufacturers can unlock new horizons of success in the dynamic realm of agricultural processing.

Design Consideration and Performance Evaluation of a Coconut

- Type: coconut oil processing machine

- Production capacity:210kw

- Voltage:380v

- Power:2.2kw

- Weight :6t, 6T

- Dimension (length*width*height):8*2*4m

The production machine is novel for easier, safer and more economical extraction of virgin coconut oil over the traditional and conventional methods. Flowchart of Sequence of Operation/Design System

This document presents the design, construction, and performance evaluation of a coconut oil extracting machine aimed at improving extraction efficiency and oil quality. The machine, which utilizes a low pressure oil extraction method, achieved a production efficiency of 69.5% and yielded approximately 20.7% oil, significantly higher than traditional methods. User experience ratings were

A comprehensive review on the techniques for coconut oil

- Usage: coconut oil

- Production capacity: 1TPD-1000TPD

- Voltage: 380V/440V or required

- Function: Edible oil manufacturing

- Weight: 5500KG, 5500KG

- Dimension (L*W*H): 2900*1850*3640mm, 2900 *1850*3640mm

This method however requires a longer time to extract coconut oil as it needs to settle for days . An automated coconut oil extraction machine applying this method of extraction is designed by Fabian in year 2018. Without using the automated machine, the maximum percent oil recovery of VCO is at 88.35% and a yield of 30–31%.

Discover the diverse techniques behind Coconut Oil Extraction Methods, from traditional approaches to modern innovations like cold pressing, hot extraction, and centrifugation. Unveil the quality and yield disparities between cold pressing and hot extraction, as well as the purity and efficiency advantages of centrifugation. Stay informed about the evolving methods that drive the multi-billion

CoCoMaN Coconut Machines

- Type: cooking oil extraction machine

- Production capacity: 1TPD-1000TPD

- Power(W): 7.5kw

- Voltage: 220V/380V/440V

- Dimension ( L*W* H): 1200*400*900mm3

- Weight: According to baking press capacity

Specifically designed for coconut processing from dehusking to coconut oil extracting, coconut husk processing and coconut shell processing. We have exported and installed our coconut machines in countries such as Indonesia, south africaia, Ghana, Papua New ethiopia, Fiji, Tahiti, Bahamas, Dominican Republic, Guyana, Ecuador and Mexico.

point of refined coconut oil is higher than that of unrefined coconut oil. Hence, it can be heated up to 204 °C. This oil is best for recipes that do not desire natural coconut flavor and scent. The manufacturing process of this oil includes extracting oil from copra or dried coconut meat and steaming it to remove the natural aroma of coconut.

Design Consideration and Performance Evaluation of a Coconut

- Raw Material: coconut

- Product Residual oil in cake: 1%

- Solvent: n -hexane

- Keyword: oil mill machinery prices

- Voltage: 380V or 440 V

- Extractor dimension ( L*W*H): according to capacity

B. Methods Description of The Coconut Extractor; The coconut oil extractor is shown in figures 1 and 2. Key components of the extractor include a rigid frame that forms a firm housing for other machine components, a feed hopper that forms a receptacle for the admission of coconut milk, a cylindrical extraction chamber, oil and cake outlets, a power unit, and a shaft assembly.

The chip is heated by the heating system after which it is pressed. The coconut oil drops on the oil tray, it passes through the oil tray to the oil tank. A 5kg sized Copra was used to examine the performance of the machine. Data obtained reveal that the required heating time was 15mins with a heater band of 2000 watts at 80°C.