Copra Grinder Machines for pressing cold coocnut oil

- Type: coconut oil extractor machine

- Usage/Application: coconut, copra

- Certification: SGS,CE,ISO

- product type: cooking oil machinery

- project: Turkey project

- warranty period: 12 months

- business scope: FFB to CPO or CPKO

- Country: zambia

Copra grinder machines epitomize technological ingenuity, offering a gateway to enhanced efficiency, superior quality, and sustainable practices in coconut oil extraction. By embracing innovation and leveraging advanced machinery, manufacturers can unlock new horizons of success in the dynamic realm of agricultural processing.

Design and Fabrication of Portable Virgin Coconut Oil

- Type: coconut oil processing machine

- Press Materials: Oil Crops

- Press Series: Second

- Advantage: Easy operation

- Capacity: 1-1000 tons

- Custom: Custom

The proposed portable machine can be operated manually without skills or much power. It consists of a screw rod, cylinder, piston plate, tray, and frame to apply pressure to coconut meat and extract the oil. The machine is compact, low-cost, durable, and efficient at extracting virgin coconut oil for both domestic and commercial use.

Mechanical Coconut Oil Extraction Process: the dry coconut with 10% ~ 12% moisture is transported to the automatic scale to remove the broken iron through the magnetic chamber, and is ground into particles of about 0.3 cm in diameter, and the particles are pressed into a thin sheet to enlarge the surface of the dried coconut oil extracting.

Design Consideration and Performance Evaluation of a Coconut

- Usage: coconut oil

- Voltage: 220/110 V

- Dimension (L*W*H): 450*180*305MM

- Function: Oil seed press

- Main components: Motor

- Weight: 15KG

The production machine is novel for easier, safer and more economical extraction of virgin coconut oil over the traditional and conventional methods. Flowchart of Sequence of Operation/Design System

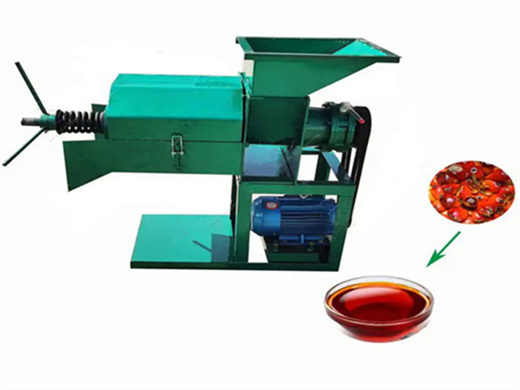

B. Methods Description of The Coconut Extractor; The coconut oil extractor is shown in figures 1 and 2. Key components of the extractor include a rigid frame that forms a firm housing for other machine components, a feed hopper that forms a receptacle for the admission of coconut milk, a cylindrical extraction chamber, oil and cake outlets, a power unit, and a shaft assembly.

Coconut Oil Extraction Machine - Oil Expeller

- Type: cooking oil extraction machine

- Voltage: 380 V

- Main components: motor, pressure vessel, pump, PLC, gear, bearing, motor, gearbox , others

- Weight: 1000 KG

- Oil ProductRaw material: Sunflower, Palm, Sesame, Olive

- Function: Essential oil extraction

Hence it is also called cold pressed coconut oil. (Read more: Virgin Coconut Oil (VCO) Extraction Plant Process) Expelled Coconut Oil – Made from Copra. Extracted from dried coconut meat – Copra. The coconut is dried in the sun or in a drier before pressing the oil. The copra is then sent to a coconut extracting machine to obtain crude oil.

When customers use specialized oil extraction machine for coconut oil processing, they need the right pressure, precise temperature control and a durable and efficient mechanical system. Benefiting from more than 20 years of professional experience, we manufacture high quality parts to ensure robust and durable machines that have been

Cold & Hot Pressed Coconut Oil Making Machine For sale

- Raw Material: coconut

- Production capacity: 20~2000T/D

- Power ( W): 7.5kw

- Voltage: 380v/50Hz

- Dimension (L*W*H) : 2050*1350*2000Weight: 1000kg

- Function: oil machine line

The coconut oil screw press machine, also known as a screw oil extraction machine, is a high-efficiency oil pressing equipment, which uses the rotation of a screw shaft to extrude the coconut oil while extruding the oil cake with the help of mechanical force. The following are the outstanding features of the oil extraction machine.

Coconut Milk Extractor. Input Capacity- Upto700kg of white meat Output Capacity- upto 350 Ltrs of milk • High juicing rate,good quality and high capacity. • The milk extracting rate of the virgin grind is more than 50%. • Automatically and continuously separate process.