Sunflower Oil Production Plant Process Flowchart - GOYUM GROUP

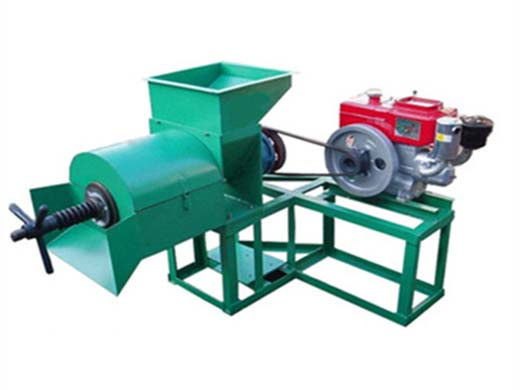

- Type: sunflower oil processing equipment

- Usage/Application: sunflower

- Production capacity: 1TPD-1000TPD

- Voltage: 220 V

- Weight: 130kg

- Dimension (L* W*H): 46*32*36cm

- Power (W): 5.5 kW

- Country: kenya

Wide application of Sunflower Oil Production. Cooking Oil: Sunflower oil is known for its premium characteristics such as light colour, bland flavour, rich unsaturated fatty acids, low linoleic acid and high smoke point. From improving heart health and keeping the skin glowing from within to boosting energy and strengthening the immune system

Invest in Affordable Small Sunflower Oil Production Line

- Type: sunflower oil processing machine

- Product extraction system: roasting system

- residual oil content: maximum 1%

- Capacoty: according to your requirements

- solvent raw material: rice bran, canola, seed sunflower, peanut, soybean, groundnut, etc.

- Packaging detail: 20ft, 40ft container

Complete Sunflower Oil Processing Steps. Undertake 1~100ton/day Sunflower Oil Production Line with Cusotmized Business Plan. Complete Sunflower Oil Manfuacturing Process: Cleaning of seeds, de-hulling, oil pressing, solvent extraction and crude oil refining. Sunflower Oil Production Flow Chart

The vegetable oil produced by Kanonga’s company, Mimosa Simence, is not only replacing oil imported through Zambia but it is also offering a healthier option – her food products are organic. Ange Kanonga during an interview with some bottled sunflower oil displayed on the table.

Sunflower Oil Production Line for Sunflower Oil Plant to

- Usage: sunflower oil

- Production capacity: more than 95%

- Voltage: 220V/110V

- Main components: motor, PLC, gearbox

- Weight: 60 KG

- Dimension (L*W*H): 70*45*65CM

Sunflower oil is an excellent vegetable oil which is extracted from sunflower seeds that begin with sunflower seeds pre-treatment, pre-pressing, embryonic material leaching, wet meal desolventizing and crude sunflower oil refinery process. Sunflower seed oil is rich in linoleic acid, which helps reduce blood cholesterol levels in the body,

De-shelled pressing-leaching technology is the key point of sunflower oil production line which avoids the negative impact of over-refining, high temperature, and acid and alkali effects on oils, so that the nutrients in the oil can be well preserved. For example, the content of vitamin E in de-shelled squeezed sunflower oil is 75.5mg/100g.

Method and Process of Sunflower Oil Production Line

- Type: cooking oil extraction machine

- Production capacity: 50-1000 kg/h

- Power: 75kw+11kw

- Voltage: 380 V/440 V or required

- Dimension (L*W*H): 3740x1920x3843mm

- Weight: 9000kg

Hongde complete sunflower oil production line capacity 10-5000TPD can be customized for design, manufacturing, installation and debugging. Sunflower seeds is a common oilseeds, in which there are 45-54% oil content.

Capacity 1 TPD to 5,000 TPD. The sunflower oil production line includes cleaning, shelling, kernel separation, cooking, pressing, filtering, extracting, refining, and packing. Some steps can be customized based on specific requirements, fully automated or semi-automatic options for varying budget levels.

Start Sunflower Oil Production Line in kenya

- Raw Material: sunflower

- Dimension (L*W*H): 1*1*1

- Main components: Others

- Weight: 100 KG

- Oil Product Feature: High quality material

- Used for: Oil press equipment

Buy sunflower oil extracting machine kenya from solvent oil extraction plant equipment manufacturer or supplier at factory price, get FREE technical instruction of sunflower oil extraction process and business plan to set up sunflower oil extraction project in lesotho, Panama, Pakistan, lusaka, Kazakhstan, etc., at low cost.

As a cooking oil, it is used for frying in both commercial and home cooking. Sunflower seed oil is extracted from sunflower seed with Oil pressing machine and Extraction Machine. Sunflower seed oil pre-press line. Sunflower seed→Sheller→Kernel and shell separator→Cleaning→ metering →Crusher→Steam cooking→ flaking→ pre-pressing