What are the steps in making palm oil? - Palm oil extraction

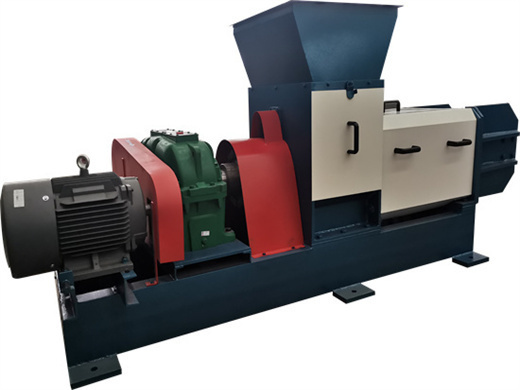

- Type: palm oil processing machine

- Usage/Application: palm fruit, palm kernel

- Production capacity: 1000~6000kg/h

- Voltage: 220V/380V

- Dimension (L*W*H): 1313*1020*1440 mm

- Weight: 240~1400kg

- Power (W): 15~45KW

- Country: zambia

The photo of packaged palm fruit oil. The above are the steps in making palm oil. In conclusion, the palm oil making process is intricate and demands precision at every step, from the initial care of palm trees to the final stages of packaging the refined product. Each stage plays a crucial role in determining the quality and yield of the oil.

Palm Oil Filling Machine: Streamlining The Production Process

- Type: palm oil processing machine

- Production capacity: ≥94

- Voltage: 380 V

- Main components: Others, Gearbox

- Weight: 750 KG

- Dimension (L*W*H): 1865*1230*1420

With a palm oil filling machine, the risk of injury is significantly reduced, as the machine automates the filling process and minimizes direct human contact with the palm oil. In conclusion, efficient production in palm oil processing is crucial for cost-effectiveness, product quality, sustainability, and worker safety.

A full range of palm oil milling equipment, with everything you need for your oil room and (crude palm oil) CPO washing; Reliable palm oil refining process technologies with complete plant solutions for bleaching and deodorizing; Advancements to improve end-product quality while simultaneously boosting capacity, limiting loss and increasing yield

Palm Oil Business Plan Proposal Sample Prepared By

- Usage: palm oil

- Customized: Customized

- Machine: Palm Oil Press

- Dry type or wet type: Wet type palm oil press

- Raw material: Palm

- Capacity: 1t /H 2t/H 5t/H Palm oil press

Palm oil is a versatile and cost-effective ingredient used in a wide range of consumer products. The increasing demand for palm oil presents a lucrative opportunity for Agrolearner.com Farm to capitalize on the market growth. Sustainable Sourcing: There is a rising emphasis on sustainable and environmentally friendly palm oil production.

Palm oil processing By Shamsul Bin Zakaria http://ocw.ump.edu.my/course/view.php?id=68 The student should be able to understand and compare: • The refining routes

Palm Kernel Oil Extraction: Traditional and Modern Methods

- Type: cooking oil extraction machine

- Production capacity: High

- Dimension (L*W*H): 1200*800*1160 mm

- Voltage: 220 V

- Weight: 230 KG

- Warranty: 1 year, one year

Higher Oil Yield: Extracts almost all available oil from the palm kernel cake, achieving up to 98% oil recovery. Efficiency and Cost-Effectiveness: The ability to recover and reuse the solvent reduces processing costs and minimizes waste.

The oil is rich in palmitic acid, β-carotene and vitamin E. CPO has been fractionated mainly into liquid palm olein and solid palm stearin in order to diversify its food applications.

[Beginners Guide] How To Process Palm Oil

- Raw Material: palm

- Production capacity: 45 sets per year

- Power (W): 30KW

- Voltage: 380V/440V

- Dimension (L*W* H):1200*2800*1200mm

- Weight:500TON

Benefits of Processing Palm Oil. Processing palm oil offers several benefits that contribute to its value and usefulness. Some key advantages include: Improved Quality: Processing palm oil allows for the removal of impurities, resulting in a higher-quality oil that is free from contaminants. The refining process removes undesirable components

Before extracting oil, the palm fruits need to be crushed in digester machines. To augment oil yield, the fruit pulp is also warmed in this process. The mesocarp and nuts can be squeezed together in palm oil making/pressing machine. But if you plan to make Grade A Palm Oil, the palm nut/kernel should be removed before oil pressing section.