Physical and Chemical Process in Palm Oil Refining Plant

- Type: palm oil refinery machine

- Usage/Application: palm fruit, palm kernel

- Feature: Waterpoof

- Material: Vinyl Paper

- Color: As per design

- Industrial use: Food

- Custom Order: Accept

- Country: lagos

It adopts vacuum system to remove the impurities and color pigments from the crude palm oil and crude palm kernel oil. Deodourising process; The palm oil and palm kernel oil are steamed at a temperature of 240°C to 260°C to get away the odors and tastes, and then they are cooled into room temperature (about 55°C) for further use.

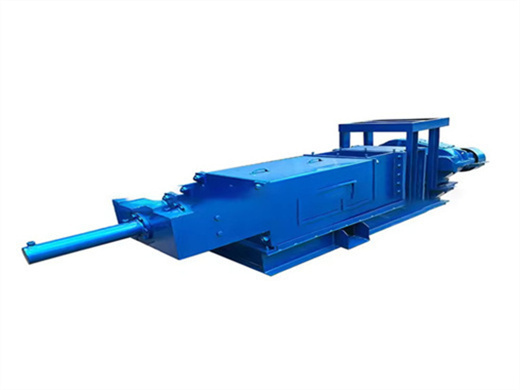

Palm Oil Refining Machine

- Type: palm oil refinery machine

- Production capacity: 2T/D---10T/D

- Voltage: 380v/50Hz

- Weight: as per specification

- Dimension (L*W) *H): 1360*950*1170mm

- Power (W): up to specification

Palm Oil Refining Machine. Palm Oil Refinery is the main oil machinery and equipment to ensure the quality, grade and edible safety of oil in the palm oil processing process. The palm oil refining machine produced by Henan Hongde Cereals and Oils Machinery Co., Ltd. can flexibly adapt to different production needs with advanced technology

In order to obtain high-quality palm oil, crude palm oil needs to be refined through palm oil refining machine. The purpose of palm oil refining is to remove phospholipids, FFA, pigments, gums, waxes, odors and other impurities in crude palm oil. We can provide palm oil refining machine from 1 ton to 1000 tons. Generally speaking, the

Palm Oil Refining Processing Machinery - Find Edible Oil

- Usage: palm oil

- Voltage: 220V/380V

- Power (W): According to capacity

- Grade: high

- Weight : 1050 KG

- Dimension (L*W*H): 1610x615x1260mm

Physical Refining of Palm Oil; Physical refining is also known as steam refining. In degumming process, it utilizes citric acid or food grade phosphoric acid to remove natural gums in the form of phosphatides. Then, in bleaching process, under vacuum, Fuller’s Earth is used to remove colouring matters and adsorb any metal ions.

Palm kernel oil refining processing line adopts advanced and scientific physical refining and totally stainless steel tank refining. Palm kernel oil is non-drying oil with low gum content, which is suitable for physical refinery. Fatty acid composes of 45%-51% lauric acid and 13%-25% cardamom acid. Palm kernel oil contains soap grade and food

Palm Kernel Oil Refining - Palm Oil Mill Machine Leading

- Type: cooking oil refining machine

- Voltage: 220V/380V/440V

- Dimension (L*W*H): 1050*660*760mm

- Power (W): 11KW

- Weight: 700kg

- Material: 304 stainless steel

Palm kernel oil contains soap grade and food grade.The process of Palm kernel oil refinery is to refine the crude edible oil, to remove gossypol, protein, phospholipid, grume, moisture and other impurities, in order to reach the purchase of food and storage.The process of palm kernel oil refinery includes mechanical refinery method, chemical

The main palm kernel oil refinery process is: crude palm kernel oil degumming neutralization decolorization deodorization process. During palm kernel oil refinery process, we adopts water hydration degumming, alkali neutralization or steam distillation deacid, adsorbent activated clay or activated carbon decolorization, high temperature

Best Palm Kernel Oil Refinery Machine Supplier | Manufacturer

- Raw Material: palm

- Production capacity: 1-500T/D

- Power (W): according to capacity

- Voltage:380 V

- Dimension (L*W* H): various with capacity

- Weight: changes with capacity

Oil refinery, commonly known as "oil refining", uses physical and chemical methods to remove the solid impurities contained in crude palm kernel oil, like free fatty acids, phospholipids, gum, wax, pigment, odor through a series of Palm Kernel Oil Refining Process collectively, which finally can improve the tasete, quality and shelf-life of

Main process of palm kernel oil refinery plant: 1. Crude palm kernel oil degumming process: degumming process aims to removing the gum impurities in the crude oil to make it suitable for further refinery process. Physical oil refining is applicable because of low gum content in palm kernel oil. 2.