(PDF) Defatting and Defatted Peanuts: A Critical Review on

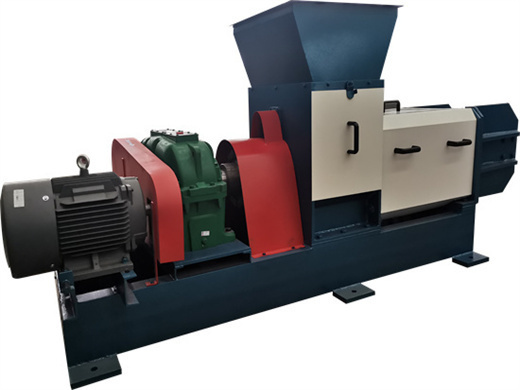

- Type: peanut oil extraction machine

- Usage/Application: peanut, groundnut

- Warranty: 2 years

- Main components: motor, fan

- Power: 2.2kw+0.75

- Capacity: 13~100t/h

- Product /Function: Remove Impurities

- Country: botswana

This review elucidates the methods used for extracting peanut oil, including mechanical and chemical processes that have been combined with biological or physical pre-treatment techniques.

Effect of glycerol, peanut oil and soybean lecithin contents

- Type: peanut oil processing machine

- Production capacity: 10-1000T/D

- Voltage: 380V/220V

- Key selling points: Energy saving

- Weight: changed according to capacity

- Dimension (L*W*H): various with capacity

with added glycerol, peanut oil and soy lecithin were determined. Starch was obtained by cold water extraction from native cassava from the varieties Bocou 1, Bocou 2, Yavo and TMS. Films preparation was made bycasting method with cassava, glycerol (25-30 %), peanut oil (5-10 %) and soybean lecithin (0-5 %). Increasing the glycerol

2.2.2 Oil Content and Physicochemical properties of peanut oil Soxhlet apparatus using n-hexane as the solvent was used for the extraction of the oil. The specific gravity of the oil was determined by using pycnometer, and its specific gravity was calculated by the following formula (2): Specificgravity¼densityof oil=densityof water: ð2Þ

Peanuts Mechanical Methods of Oil Extraction from

- Usage: peanut oil

- Voltage: 220V/380V/440V

- Power (W): 22kw

- Certification: ISO CE

- Weight: 30 tons

- Dimension (L*W*H): 48m*12M*15M(30TPD)

techniques for oil extraction from peanuts are grouped into three main sections: extrusion and screw pressing, cold pressing, and hydraulic pressing. oil extraction mechanical methods defatting peanuts defatted peanuts peanut proteins texturization MEPSI 1. Introduction Peanut, or

processing most widely used is the peanut oil. The peanut cake or meal obtained after oil extraction which can be full fatted, partially defatted or defatted is later used as flour, isolates and concentrates [6]. Oil extraction from the peanut kernel is a well-established industrial since the early 1950s. They have thus supported in

Peanut Oil Processing Technology - ScienceDirect

- Type: cooking oil extraction machine

- Main components: motor

- Arc current: standard

- Rated Duty Cycle: Standard

- Pilot arc current: standard

- Pulse frequency: standard

The leaching procedure mainly makes use of the solid-liquid extraction principle to select certain fat-dissolving organic solvents to extract the peanut oil. Generally speaking, the leaching solvent should meet the following conditions: good fat solubility, stable physiochemical properties, easy separation from the fat and meal, and be safe

Peanuts, being crucial crops of global importance, have gained widespread recognition for their versatility and nutritional value. In addition to direct consumption, either with or without treatment, peanuts can be the subject of diverse applications focusing mainly on two distinct objectives: oil extraction and defatting processes. As a result of the first process, a solid matrix is generated

Peanut proteins: Extraction, modifications, and applications

- Raw Material: peanut

- Production capacity: 10 - 5000 TPD

- Power (W): As output of cooking oil extraction machine every day

- Voltage: 380v 440v

- Dimension (L*W*H): Depends on the output of cooking oil extraction machine per day

- Weight: Depends on production

Peanut oil is typically isolated from peanuts using conventional extraction methods, such as mechanical pressing and solvent (n-hexane) extraction [29]. However, many of the peanut proteins are denatured as a result of high temperatures during pressing or due to exposure to the organic solvent.

the traditional oil extraction process, aqueous enzymatic extraction has the advantages of being environmentally friendly, nonuse of organic solvents, low energy consump-tion, and mild reaction conditions2, 3). Furthermore, peanut oil requires low degree of refinement and peanut protein can be recycled at the same time4-6). Cell wall