Cottonseed Oil Production Line

- Type: cottonseed oil making equipment

- Usage/Application: cottonseed

- Voltage: 380V or according to your request

- Power (W): according to your requirements.

- Weight: According to your requirements.

- Dimension (L*W*H): According to your requirements

- Dimension (L*W*H): According to your requirements

- Country: rwanda

The deodorization process can not only remove the odors from crude cottonseed oil, but also improve smoke point, flavor, steadily and quality of final oil. At last, cottonseed oil refining has a special process -- cottonseed oil fractionation process. It is to seperate the solids and liquids in cottonseed at a specific temperature.

Steps of Cottonseed Oil Processing Process - Oil Mill Machinery

- Type: cottonseed oil refinery machine

- Production capacity: 1-100T/D

- Voltage:380V/440v

- Weight: depends on capacity

- Dimension (L*W*H): depends on capacity

- Power (W) : 20-50KW

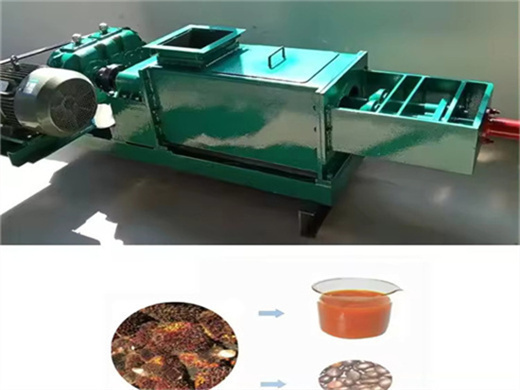

The residue & solid powder is separated through automatic oil-dreg separator. After separating, we can get two products, one is crude oil with impurity of 1% which will be refined or filtered further by Filtered Press; the other is residue with oil which is conveyed back into Screw Press to repress to get rest oil. Cottonseed Oil & Cottonseed Meal

The report on the cottonseed oil market provides an overall analysis, market size and forecast, trends, growth drivers and challenges as well as vendor analysis covering around 25 vendors. (source: researchandmarkets.com) Application of Cottonseed Oil. The cottonseed oil is cholesterol free and extracted from the seeds of various cotton plants.

Complete Equipment and Machinery for Cottonseed Oil Mill Plant

- Usage: cottonseed oil

- Voltage: 380 V

- Power (W): Standard

- Certification: CE,ISO

- Weight: Standard

- Dimension (L*W*H): Standard

Manufacturing of cottonseed oil requires particular storage climate conditions. This heating criteria should be maintained during the entire transport chain. The tanks that are needed for transporting cottonseed oils must be completely dry. There should be no ventilation under any circumstances. Cottonseed oil exhibitions 3rd order biotic activity.

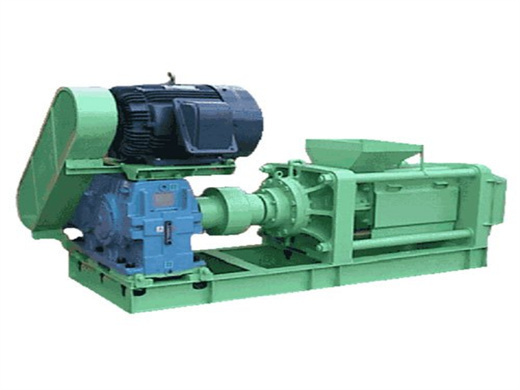

One of the widely used machine used in cottonseed oil manufacturing plant is screw cottonseed oil machine, a type of cottonseed oil machinery. It’s very simple in nature and can be used to extract oil from various seed plants. The screw cottonseed oil press is a mini cottonseed oil machine that can be used for small-scale extraction oil plants.

How To Establish Small Scale Oil Mill of Cotton Seed? Mini

- Type: cooking oil refining machine

- Product type: Nut and seed oil

- Cultivation type: COMMON

- Processing type: Refined

- Packaging: Bottle glass, bulk, can (Tinned), Drum, Jar, Plastic bottle

- Purity (%): 100

Read more about cottonseed oil solvent extraction method >>. Set Up A Cottonseed Oil Mill Plant. This small small oil mill is not only suitable for cotton seeds, it is also ideal choice for extracting oil from many other oil seeds and nuts, such as mustard seed, peanut, flaxseed, linseed, poppyseed, groundnuts, sesame seed, canola seed, sunflower seed, soybeans, etc.

For large cottonseed oil production lines with capacities of over 30 TPD, the solvent extraction method is usually adopted working together with cottonseed oil pre-press to maximize the oil yield. The large cottonseed oil production line includes a cottonseed pretreatment and pre-pressing workshop , a cottonseed cake solvent extraction workshop

Mini/Small Solvent Extraction Equipment for Cottonseed Oil

- Raw Material: cottonseed oil

- Production capacity: 180 kg/h

- Dimension(L*W*H): 1270*570*640

- Voltage: 220 V/380 V

- Weight: 430 KG

- Warranty: 1 year, cooking oil filter machine backed by 1 year

The oil content is up to 35~45% and the protein content is about 39%. Cottonseed oil contains a lot of essential fatty acids for human consumption. The refined cottonseed oil is popular edible oil around the world. (Read more: Edible Oil Manufacturing Plant Cost >>) New Cottonseed Oil Extraction

Thanks to our extensive experience with refined cotton manufacturers in the chemical fiber industry, it can be seen from the experimental data in the past five years that this set of refined cotton production equipment can reduce COD emissions, enabling the cotton lint processing enterprises to reduce chemical emissions and develop in the direction of environmental protection and energy saving.