Soybean Oil Expeller Machine in bangladesh

- Type: soybean oil expeller

- Usage/Application: soybean

- Voltage: 220V

- Screw size: 235mm

- Press per hour: 3-5 kg

- Motor power: 200 W

- Rated power: 610 W

- Country: bangladesh

Setting up a soybean oil refinery plant is an ambitious but rewarding venture now. With the increasing demand for high-quality soybean oil, understanding the intricacies of the refining process and the necessary refining machines can significantly boost efficiency and profitability. This blog will walk you through the essential soybean oil refinery process steps, machines, and considerations for starting your own soybean oil refinery business.

Nut Hydraulic Press Oil Machine in bangladesh

- Type: soybean oil processing machine

- Voltage: 220V/380V

- Power (W): 18.5kw

- Raw material: order various seeds

- Weight: 1100kg

- Dimension (L*W*H): 2050*1350*2000mm

It has the advantages of high oil yield, no pollution to oil, and so on, and it is suitable for nut products, peanut sesame, and other production lines. In general, the oil press is used in conjunction with the baking machine. Contents hide. Features. 1. Hydraulic oil press, imported Korean technology, beautiful appearance, high pressure, low

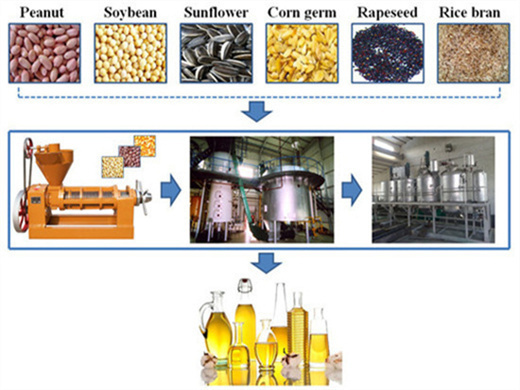

There are two methods of soybean oil production, one is mechanical way, which is a traditional method that use screw press machine to squeeze oil out from seeds and kernels; the other way is chemical method that extract oil with solvents. Both two oil production methods have advantages and disadvantages. The previous one is natural and healthy but the oil yield is much lower, however, oil yield of the solvent extraction method is much more higher. You can choose one according to the capacity and your oil making needs, or you can use the two together.

Turnkey Soybean Oil Processing Project Installed In Africa

- Usage: soybean oil

- Production capacity: 100-2000 tons

- Voltage: 380v 440v

- Weight: depends on the corn oil machine capacity

- Dimension (L*W*H) ): According to the capacity of corn oil machine

- Power (W): As production of corn oil machine every day

This is a turnkey soybean oil mill plant established in Africa for one of our customer, and this unit consists mainly of oil expeller, oil filtering equipment, cooking kettle, cleaning equipment, etc. It is a turnkey project with a raw material extraction capacity of 50 tonnes per day.

Prior to the mechanical extraction of oil, soybean is processed inside the extrude barrel, the soybeans are being compressed, ground and heated that frees the oil by rupturing oil seed cell walls. Due to dry extrusion the fat cells open and as a result fats are easily digested by domestic animals.

flax seed oil expeller machine palm oil extractor in bangladesh

- Type: cooking oil extraction machine

- Production capacity: 80-5000 kg/h

- Voltage: 380 V

- Main components: motor

- Weight: 590 KG

- Dimension (length x width x height): cotton candy machine

Flaxseed oil press machine/Flaxseed oil expeller machineThe above video is 1-5tph small scale palm oil processing machine 3D animation, from this video,

Oil Expeller / Oil Press – G 150; Oil Expeller / Oil Press – G MK-IV; Oil Expeller / Oil Press – G MK-V-C; Oil Expeller / Oil Press – G 240; Oil Expeller / Oil Press – G 600; Oil Expeller / Oil Press – G 1500; Oil Expeller / Oil Press – G 2400; Oil Expeller / Oil Press – Palm Kernel; Soybean Extruder; Seed Preparatory Equipments

Oil Mill Machinery, Oil Expeller, Seed Cleaner, Decorticator

- Raw Material: soybean

- Production capacity: 1t/day-1t/hour-100%

- Dimension (L*W*H): 2100* 1500*1750 mm

- Voltage: 380V/50HZ

- Weight: 920 KG

- Main components: Motor

We bought Oil Mill Spare Parts in the year of 2010 " Mr. Abdul - Saudi Arabia "Recently Gagan International has supplied us Refinery Plant, the plant is running since more than a year ago and we have pleasure to certify that it is running to the higher than rated capacity with consistent quality. the plant has achieved the guarantees given by

Expeltec systems would basically consist of the following: 1. Seed intake, storage, aeration, fumigation systems: It is crucual that seeds be received correctly, dried if too wet to avoid spoiling, stored properly and aerated when required to maintain quality and finally fumigated when necessary to avoid losses and to maintain oil quality and quantity.