Coconut Processing Plant Report 2025: Setup & Cost - IMARC Group

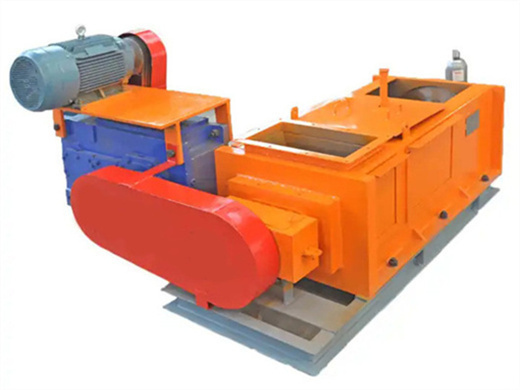

- Type: coconut oil extraction equipment

- Usage/Application: coconut, copra

- Production capacity: 100%

- Voltage: 220V/380V

- Weight: 1000 kg

- Dimension (L*W*H): 1.5* 2.6*3.6 M

- Power (W ): 7.5 kw

- Country: lagos

The report also provides detailed information related to the process flow and various unit operations involved in a coconut processing plant. Furthermore, information related to mass balance and raw material requirements has also been provided in the report with a list of necessary quality assurance criteria and technical tests.

How Coconut Oil Is Made: The Surprising Truth & Process

- Type: coconut oil processing machine

- Production capacity: 100TPD

- Voltage: 220V/380V

- Weight: According to the capacity of peanut screw oil presser machine

- Dimension (L *W*H): 1200*400*900mm3

- Power (W): According to the capacity of the peanut screw oil press machine

The journey of coconut oil production progresses with the heating of either the freshly extracted coconut milk or the dried coconut meat known as copra. In the wet mill method, the coconut milk is gently heated, allowing the lighter oil molecules to separate and rise to the top, a process that can be enhanced by fermentation or other separation

If you’re thinking to start an own Coconut Oil Production Plant and invest in Coconut Oil Manufacturing business, feel free to contact us. We help you setting up a Complete Copra Oil Mill plant , also can offer a turnkey project plan, including factory layout design, equipments manufacturing, onsite plant installation and commissioning,

Coconut Food Production

- Usage: coconut oil

- Production capacity: 1-100T/DAY

- Voltage: 380v

- Main components warranty: 5 years

- Weight: 6000 KG

- Dimension (L*W*H): according to capacity

Figure 6.1 Integrated Processing of Coconut Products (Flowchart) Coconut water is also considered a by-product of desiccated coconut or coconut milk production, where the mature coconuts are collected and halved. As consumers increasingly demand the best quality coconut water, manufacturers prefer to drill the mature coconuts instead.

Syndicated Analytics latest report titled "Mascara Manufacturing Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost

Simplified process flow diagram of a coconut processing plant

- Type: cooking oil extraction machine

- Unit Dimension (length x width x height): 2280 1250 1380 mm

- Cutting width: 110 cm

- Weight: 268

- Feed: 0.6 kg/s

- Matching power: 188F diesel engine

The common process flow diagram of a typical coconut mill/ processing plant is illustrated in Figure 1. The coconut milk to be dispatched from coconut mills are used by food manufacturers to

Coconut water (CW), also called coconut juice (not to be confused with coconut milk), is a sweet refreshing drink taken directly from the inner part of coconut fruits [6].Itdiffersfromcoconutmilk,whichisthe oily white liquid extracted from the grated fresh kernel. The coconut water consumed as a beverage usually comes from immature coconut

What Are the Different Methods of Coconut Processing?

- Raw Material: coconut

- Suitable for: sunflower, soybean, peanut

- Capacity: 15-18t/D 25t-30t/D

- Machine type: cooking oil extraction machine

- Motor power: 30kw-37kw

- Machine size: 2700*1000*2700mm

The manufacturers rely on the latest varieties of coconut machinery to efficiently process the coconut fruit. It includes the following – 1. Coconut Dehusking. This process involves separating the coconut husk by using the dehusking machine. 2. Coconut Deshelling. In this process, the manufacturers crack the outer shell of the coconut fruit.

In Detailed Project Report Here we cover Commercial Coconut Processing Unit Process, Technology and its formulation. Latest Proven Process and Technology is used for Coconut Processing Unit. We will also arrange the Technology transfer. It is the Core your business total business is Depend on Coconut Processing Unit Process and Technology.