Cotton Seed Oil Refining Machine Equipment in bangladesh

- Type: cottonseed oil line

- Usage/Application: cottonseed

- Production capacity: 1-2000TPD

- Voltage: 220V/380V/440V

- Weight: 1200kg

- Dimension (L*W*H): 2000x1400x1850mm

- Power ( W): 7.5kw

- Country: bangladesh

You can get 14% to 25% oil from cottonseed and 30% to 40% oil from the kernels. The hulls also have residue wax, pesticide, brown pigment, and lint, which can compromise the quality of cottonseed products. Cottonseed oil processing equipment is a continuous oil making equipment. It can use organic solvents to dissolve grease.

How is cottonseed oil extracted? | cottonseed oil processing

- Type: cottonseed oil refinery machine

- Production capacity: 20 TONS/DAY

- Voltage: 50 HP

- Main components warranty: 5 years

- Weight: 6000 KG

- Dimension (L*W*H): 2261MM*686MM*1423MM

Refining equipment: The degreased cottonseed oil enters the refining equipment, and impurities, pigments and odors are further removed by chemical and physical methods to obtain refined cottonseed

Dingsheng provide smart cottonseed oil and cottonseed deep processing solutions, covering the entire supply chain - for cottonseed pre-treatment, cottonseed cake solvent extraction, crude oil refining, cottonseed oil hydrogenation, refined cotton cellulose, cottonseed protein and more.

Steps of Cottonseed Oil Processing Process - Oil Mill Machinery

- Usage: cottonseed oil

- Power source: Electric

- Voltage: 380V 50HZ (can be customized)

- Dimension (L*W*H): about 8400*850*2050mm

- Weight: 1300kg

- Power (W): 15 KW

The residue & solid powder is separated through automatic oil-dreg separator. After separating, we can get two products, one is crude oil with impurity of 1% which will be refined or filtered further by Filtered Press; the other is residue with oil which is conveyed back into Screw Press to repress to get rest oil. Cottonseed Oil & Cottonseed Meal

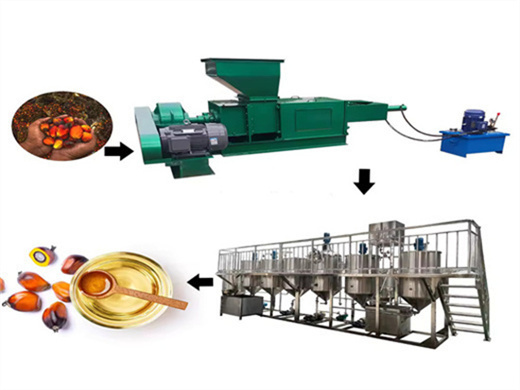

Then, the crude cottonseed oil is made and the cottonseed oil cake is discharged for next processing for feed or other usages. Oil Refining: Since the crude cottonseed oil contains high content of gossypol, it needed to be refined to improve the quality and ensure the final refined cottonseed oil is completely safe for eating.

Cotton Seed Processing, Oil Extraction & Refining Plant

- Type: cooking oil refining machine

- Production capacity: 45 kg per hour

- Dimension (L*W*H): 840*240*540 mm

- Voltage: 220-240 volts

- Weight: 67 KG

- Main components warranty: 2 years

Cottonseed could either be processed by the traditional crude method of crushing seed without Delinting in un-decorticated form or by scientific processing used for Cotton Seed Processing, which involves removal of De-linters, decortication, separation of hull, expelling, solvent extraction and refining of oil. Scientific processing of Cotton

10-20T/D Edible Oil Production Line; 1-50T/D Edible Oil Production Line; Oil Refinery Plant. Large Continuous Edible Oil Refinery Plant 20-5000TPD; Batch-type Edible Oil Refining Equipment 1TPD to 20TPD; 10T/D Edible Oil Refinery Plant; 1-5T/D Edible Oil Refinery Plant; Cotton Seeds Oil Refinery Plants; Seed Oil Press. Integrated Screw Oil

Cottonseed Oil Hydrogenation Production Line

- Raw Material: cottonseed oil

- Voltage: 220/110V

- Main components: stainless steel

- Weight: 7 KG

- Oil type: Palm oil

- Product Function: Oil press

The use of miscella oil refining process for cottonseed oil can help remove gossypol in the process, reduce refining losses, improve oil color, improve product quality, simplify oil processing, and have better results than other refining processes. This is more suitable for refining specific oils of cottonseed oil.

Wintone as a professional edible oil refinery plant manufacture can provide design, manufacture, installation, calibration and after service of cottonseed oil refining equipment and other cooking oil processing plants.