Cottonseed Oil Extraction Plant

- Type: cottonseed oil refinery plant

- Usage/Application: cottonseed

- Production capacity: 1-500T/D

- Voltage: 380V-415V

- Weight: depends on the machine mode of oil

- Dimension (L*W*H): depends on the oil machine mode

- Power ( W): depends on the oil machine mode

- Country: nairobi

3. Cottonseed oil extraction plant has multiple oil extractors for selection and advanced mineral oil system. 4. Adopting negative pressure evaporation system, saving energy and reducing steam consumption. 5. Low residual oil rate in the meal, good oil, and meal quality. The Process of Cottonseed Oil Plant

Cotton Seed Processing, Oil Extraction & Refining Plant

- Type: cottonseed oil refinery machine

- Production capacity: high

- Voltage: 380

- Warranty: 2 years

- Weight: 3000 KG

- Dimension (L*W*H): corresponding

Cottonseed could either be processed by the traditional crude method of crushing seed without Delinting in un-decorticated form or by scientific processing used for Cotton Seed Processing, which involves removal of De-linters, decortication, separation of hull, expelling, solvent extraction and refining of oil. Scientific processing of Cotton

3.Cottonseed oil Refinery : A.Flow chart: Degumming →Deacidification →Decoloration → Deodorization →edible oil B. Points for cottonseed oil refining plant ♦ Cottonseed oil refinery can be divided into batch refining (50 t/d) depending on capacity.

Cottonseed Solvent Extraction Plant - Oil Expeller

- Usage: cottonseed oil

- Production capacity: 250-300 KG/H

- Voltage: 380V

- Weight: 2200 kg

- Dimension (L*W*H): 2000x1200x2500mm

- Power (W ): 3KW

Solvent Extraction. The cotton seed cake solvent extracted or pre-pressed cake or full pressed cake or expanded collets. The pre-pressed cake / expanded collets / fully pressed cake from preparatory section is carried by Redler Conveyor and fed to Extractor Either through rotary valve or Plug O Seal to extractor feed hopper incorporated with high and low level arrangement to ensure proper

Within the cottonseed oil processing plant, oils extracted from cottonseed must be refined to remove gossypol, a naturally occurring toxin that protects the cotton plant from insect damage. Cottonseed meal is a good source of protein. It is the byproduct remaining after cotton is ginned and the seeds crushed and the oil extracted.

Cottonseed Oil Mill / Oil Extraction Plant Manufacturers

- Type: cooking oil refining machine

- Production capacity: more than 95%

- Dimension (L*W*H): 45*21.5* 24 cm

- Voltage: 220V/110V

- Weight: 12 KG

- Main components: Gearbox, Motor, PLC

Undecorticated Cottonseed obtained after Delinting process can be used as a raw material for Cottonseed Oil Extraction Plant. Cottonseed contains 18 – 20 % oil content. After a single stage pressing, about 6 – 7 % residual oil is left in the cottonseed meal which is an excellent source of Cattle Feed.

Cottonseed Oil Decolorization. The main purpose of bleaching is to remove pigments from cottonseed oil to improve the color and appearance of the oil. First, we need to heat the degummed (or deacidified) cottonseed oil to 110-120°C. Second, add 0.5-1.5% of an adsorbent such as activated carbon or clay.

Cottonseed Oil Mill Plant

- Raw Material: cottonseed oil

- Production capacity: 1000 KG

- Dimension (L*W*H): 1100*1000*1500 mm

- Voltage: 220 V/380 V

- Weight: 1320 KG

- Advantage: Automatic and easy operation

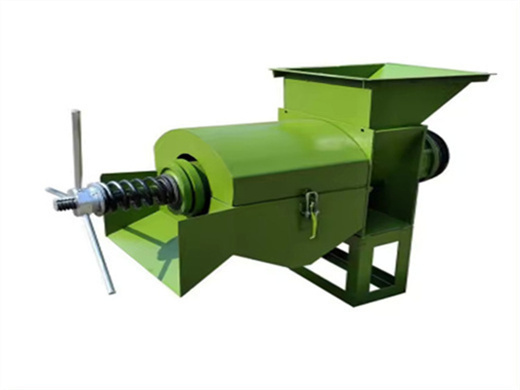

Cottonseed Oil Pressing / Expelling (by using Mechanical Screw type Oil Press); Cottonseeds can be pre-pressed before they get sent directly to the refinery plant. To handle 20 tons of cottonseed per day, the solvent extraction method is used with cottonseed oil prepress to take parts of the oil.

Cottonseed oil contains pressing cottonseed oil, solvent extraction cottonseed oil, genetically modified organism cottonseed oil, crude cottonseed oil, and finished product of cottonseed oil. Its color is deep redder than other oils, can be used as cooking oil after refining, as well as contains a large sum of fatty acid which is essential to