How To Establish Small Scale Oil Mill of Cotton Seed? Mini

- Type: cottonseed oil processing plant

- Usage/Application: cottonseed

- Production capacity: 3-8 kg/h

- Voltage: 220 V/110 v

- Key Selling Points: Energy Saving

- Weight: 13 kg

- Dimension (length x width x height): 450*180* 360 cm

- Country: johannesburg

Read more about cottonseed oil solvent extraction method >>. Set Up A Cottonseed Oil Mill Plant. This small small oil mill is not only suitable for cotton seeds, it is also ideal choice for extracting oil from many other oil seeds and nuts, such as mustard seed, peanut, flaxseed, linseed, poppyseed, groundnuts, sesame seed, canola seed, sunflower seed, soybeans, etc.

Oil Seed Processing Plants | Sesame, Sunflower & Cottonseed

- Type: cottonseed oil processing machine

- Mechanical principle: Pressure filtration

- Performance: Temperature

- Weight: 8 tons

- Power: 32kw

- Capacity: 1t/D

Explore turnkey oil seed processing plants for cleaning, sorting, dehulling, and packaging of chia, cotton, sesame, hazelnut, hemp, pumpkin, sunflower seeds, and more.

Within the cottonseed oil processing plant, oils extracted from cottonseed must be refined to remove gossypol, a naturally occurring toxin that protects the cotton plant from insect damage. Cottonseed meal is a good source of protein. It is the byproduct remaining after cotton is ginned and the seeds crushed and the oil extracted.

Cotton Seed Processing, Oil Extraction & Refining Plant

- Usage: cottonseed oil

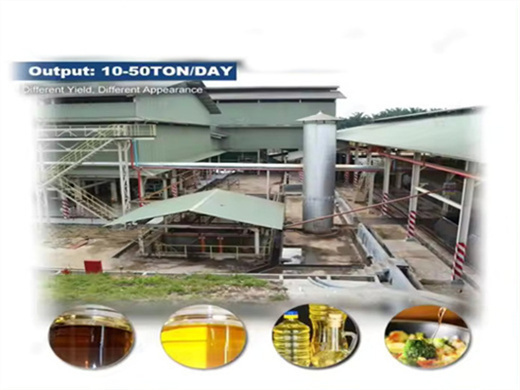

- Production capacity: 10-1000MT

- Voltage: 220V/380V/415V

- Feature: High oil performance efficiency

- Dimension (L*W*H): 1200*400*900mm3

- Power ( W): 1-30kw

Cottonseed could either be processed by the traditional crude method of crushing seed without Delinting in un-decorticated form or by scientific processing used for Cotton Seed Processing, which involves removal of De-linters, decortication, separation of hull, expelling, solvent extraction and refining of oil. Scientific processing of Cotton

The products of the cottonseed oil processing plant are cottonseed oil, cottonseed meal, cottonseed hull, and soapstock. Features of Cottonseed Oil Processing Plant. 1. Cottonseed oil mill plant has high automation degree, continuous operation, saving labor. 2. The pre-pressed cake has low residual oil rate and is easy for solvent penetration. 3.

Cotton Seed Processing Plants | Oil - Oil Extraction Plants

- Type: cooking oil extraction machine

- Weight: 1000 KG

- Oil type: Cooking oil

- Main components: Motor, Others, Gears, Motor

- Name of the item : YZYX10 Mini 11W Oil Press Machine

- Material: Cast Iron

We offer cottonseed processing plants which includes several stages of processing like delinting, dehulling, hullbeating, meats recovery, cooking and conditioning etc.The cooked meats are subjected to oil recovery by expellers. The residual oil contained in the Expeller Cake is recovered through solvent extraction process.

Cottonseed oil is extracted from the seeds of cotton plants. Refined cotton seed oil is edible. India, China, Pakistan, USA and Brazil are among the top producers of cotton seed oil in the world. Let us now know about the various aspects of cottonseed oil plant - it's manufacturing process, world market status and other features.

Complete Cottonseed Oil Production Lines. Cottonseed Oil

- Raw Material: cottonseed oil

- Production capacity: 5t/day-5t/hour

- Dimension (L*W*H): 1200*400 *900 mm

- Voltage: 220v

- Weight: 260 KG

- Main components: motor, pressure vessel, pump, PLC, gear, bearing, motor, gearbox, others

Cottonseeds can be once-pressed and then sent to the cottonseed oil refinery plant in small cottonseed oil plants. For cottonseed oil production lines with a capacity of over 20 TPD, a solvent extraction method is adopted to work together with cottonseed oil pre-press to extract the rest cottonseed oil.

Small Cotton Seed Oil Processing Plant. The pre-treatment equipment used in cotton seed oil pressing plant for cottonseed includes cleaning equipment (magnetic separator, cleaning screen and destoner), sheller, shell separating screen, embryo flaking machine, steam frying pan or cooking machine, and a series of other equipment.