Refining into refined,bleached and deodorised rbd palm oil

- Type: palm oil machine

- Usage/Application: palm fruit, palm kernel

- Production capacity: High

- Voltage: 380 V, 50 Hz, three-phase

- Oil advantages: Heavy duty, high yield

- Weight: 280 KG

- Dimension (L*W*H): 1400*600*1300 mm

- Country: lusaka

Batch type palm oil refining machine: 1-20tpd Semi-continuous palm oil refining machine: 20-50tpd Fully continuous palm oil refining machine: 50-1000tpd: Applications: Process almost all kinds of crude oil for edible purpose: vegetable oil, palm oil, castor oil, sunflower oil, rice bran oil, soybean oil, canola oil, cottonseed oil, mustard oil

palm oil line

- Type: palm oil refinery machine

- Production capacity: 50 to 200 tpd cooking oil processing

- Voltage: 220V/ 380 V/440 V

- Material: Stainless steel

- Weight: 850 KG

- Power (W): 15 kW Dimension (L*W*H): 5432*2636*2345

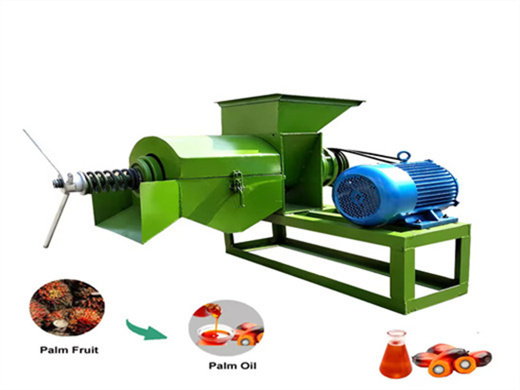

The pulp is then pressed, which bursts the oil-containing cells, releasing the palm oil. There are several types of oil making machines that may be used to press the fruit pulp, including manual presses, hydraulic presses, and screw presses. The screw press is the most commonly used palm oil making machine in both small and large scale palm oil

According to the degree of automation, the refinery process can also be divided into Batch Refinery Plant, Semi-continuous Refinery Plant and Continuous Refinery Plant. Batch type is the ideal choice for mini and small sized production (1-20TPD), while the latter two are normally designed for middle-large size production line (10-50TPD).

Palm Oil Mill Plant Production Line - QI'E Group

- Usage: palm oil

- Production capacity: 50-500 kg/h

- Voltage: 110 V/220 V

- Main components: motor, gear

- Weight: 100kg

- Dimension (L*W*H): 530*270* 350mm

The oil refining process is suitable for refining soybean oil, rapeseed oil, sunflower oil, palm oil ,cottonseed oil and etc. QI'E GROUP is a large - sized joint - equity enterprise which is specialized in producing edible oil mechanical equipment. Palm Oil Mill Plant Production Line is our unique patented technology equipment. With more than

Regarding to the palm oil refinery,the process is as follow: degumming, deacidifying, bleaching, deoodorization. fractionation. Please inform us which section you needs.or inform us the finished oil standard you want, then we can check the processing details for you. Bottles and plastice jerrycans making machine for fillwing with refined oil.

Crude palm oil refining machine and palm oil refining process

- Type: cooking oil refining machine

- Production capacity: 40-600 kg/h

- Voltage: 220v

- Main components: Motor, PLC, Others, Gear oil

- Weight: 6.5 KG

- Dimension (length x width x height): 390*150*280mm

We can provide palm oil refining machine from 1 ton to 1000 tons. Generally speaking, the production capacity of batch type palm oil refining machine is 1-20TPD; the recommended production capacity of semi-automatic palm oil refining machine is 20-50TPD; the continuous palm oil refining machine is used for production capacity above 50TPD

Simple type palm oil making machine. If you want to build a palm oil mill plant with a very sufficient budget, we have a very complete palm oil press production line, and the FOB price is about 70,000 US dollars. The main equipment includes more than 10 pieces of equipment, including sterilizer, thresher, digester, palm oil press, clarification

Palm Oil Machine - Palm Oil Production Line

- Raw Material: palm

- Production capacity: 250-300 KG/H

- Power (W ): 3KW

- Voltage: 380V

- Dimension (L*W*H): 2000x1200x2500mm

- Weight: 2200kg

The crude palm oil is refined by palm oil refining machine to remove impurities, sourness and color, and it can become clear edible oil in the supermarket; if the customer needs to produce industrial oil or cosmetic raw materials, the oil can also be separated by distillation equipment according to different melting points.

Huatai Palm Oil Mill Plant Machine. Huatai Palm Oil Mill Plant Machine Offers Complete Palm Oil Mill Plant Solutions. In addition, we also provide a professional technical team to design the whole palm oil mill plant and help customers maximize commercial profits by making the most use of the by-products produced during the process of palm oil